Spent fuel storage and cooling system

A cooling system and spent fuel technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve problems such as re-criticality, unavoidable storage safety, radioactivity, etc., to ensure flexibility and reliability, and ensure safety High performance and economy, high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

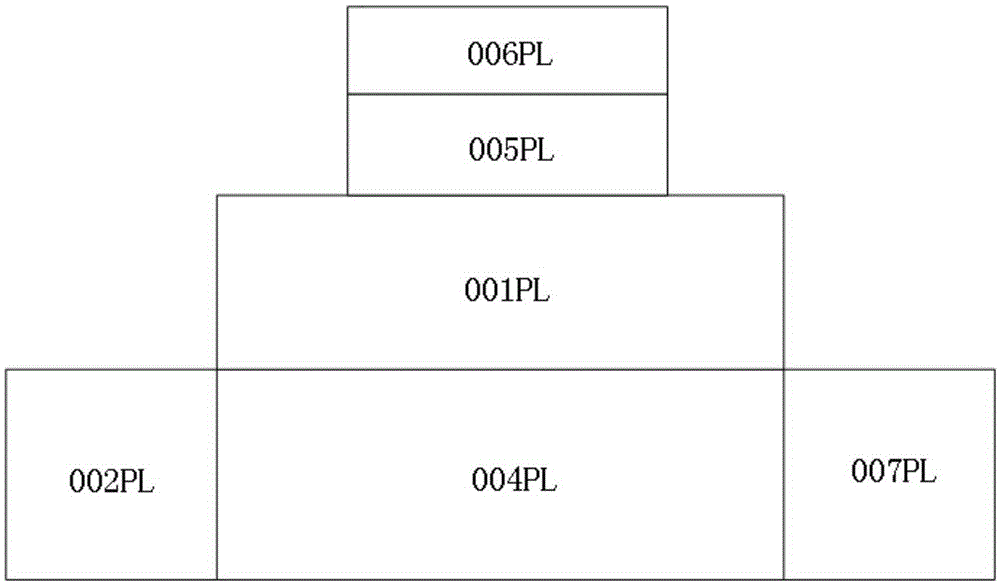

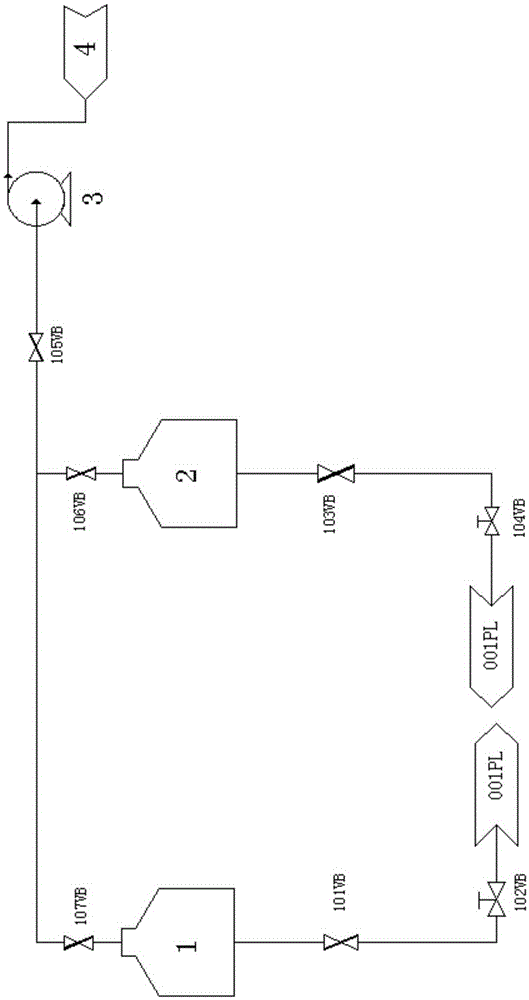

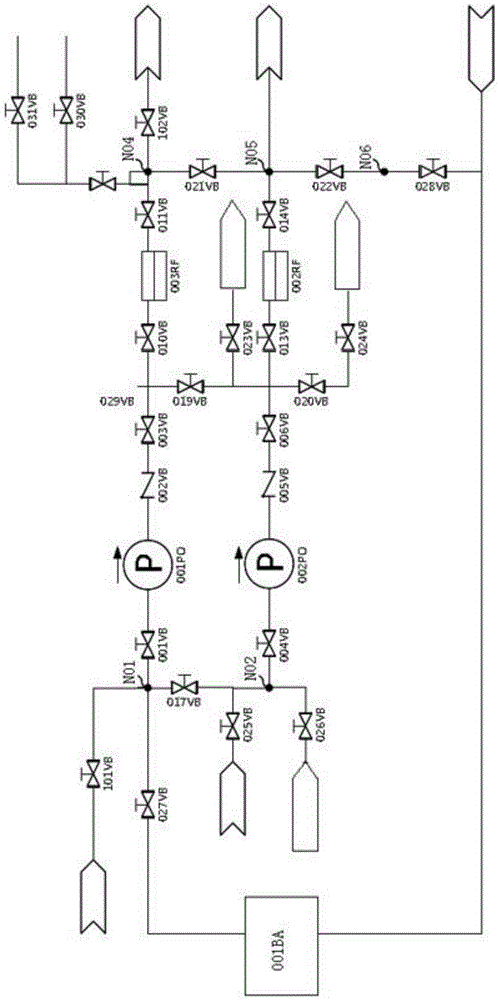

[0023] Such as figure 1 Shown is the connection diagram of the spent fuel storage and cooling system of the present invention. The storage system includes a spent fuel pool 001PL, a fuel transfer bin 004PL on one side of the spent fuel pool, a fuel loading well 005PL and a fuel flushing well 006PL on the other side of the spent fuel pool. The spent fuel pool, fuel transfer bin, fuel loading well and fuel flushing well are shared by the two piles. The storage system also includes two refueling pools 002PL and 007PL. The two refueling pools are respectively set on the two sides of the fuel transfer bin 004PL and are shared by the two stacks. Each adjacent water body is provided with a sluice gate, and an airtight device is provided on the sluice gate, and the airtight device includes an anti-shock compressed air storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com