Opening current transformer capable of being installed in powered-on mode

A technology for current transformers and shells, which is applied in the field of open current transformers, which can solve the problems of difficult compliance with partial discharge indicators, weak insulation at openings, and reduced wire holding strength, so as to avoid the problem of weak insulation, low cost, and strengthen the holding The effect of line strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

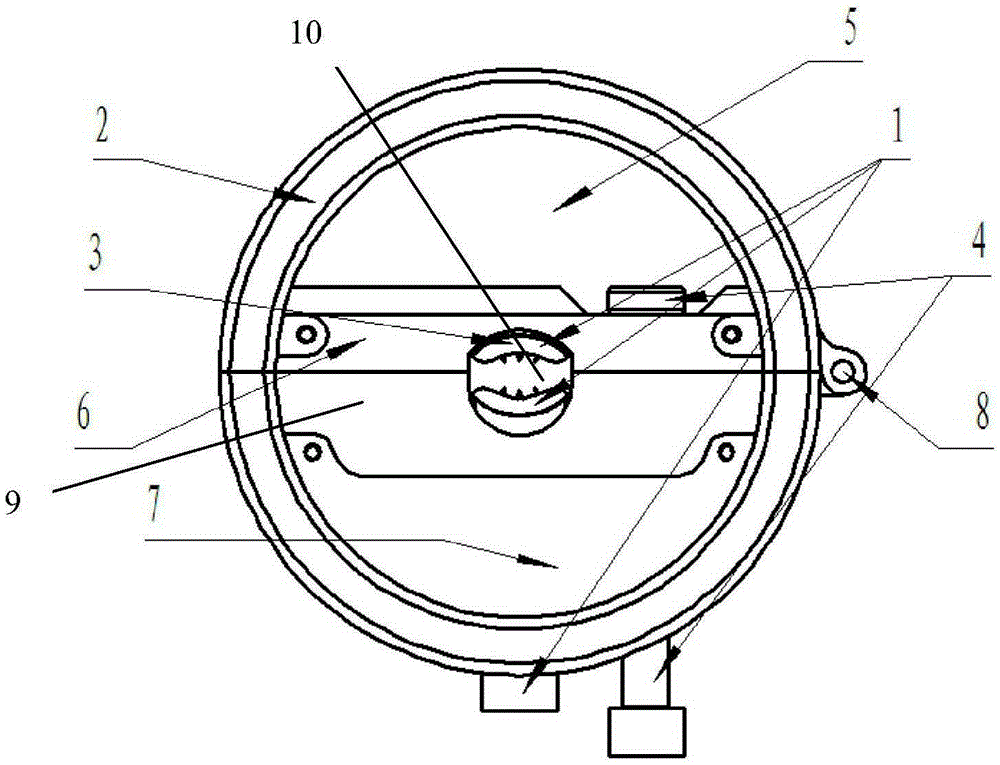

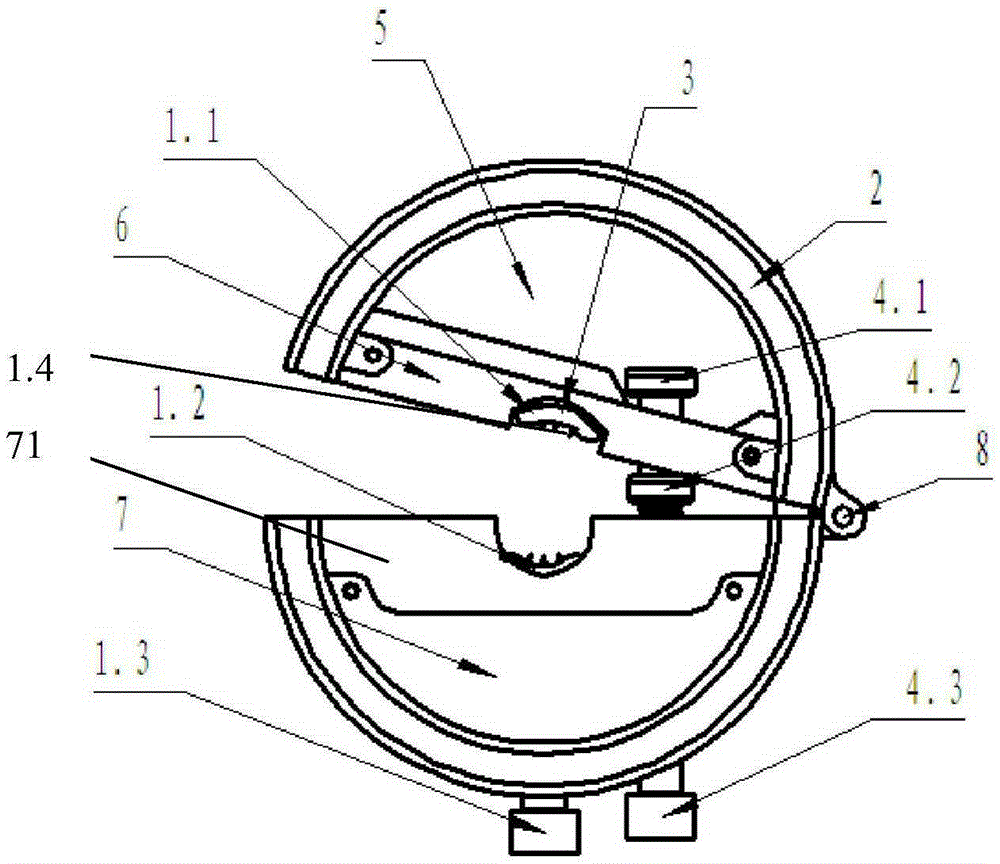

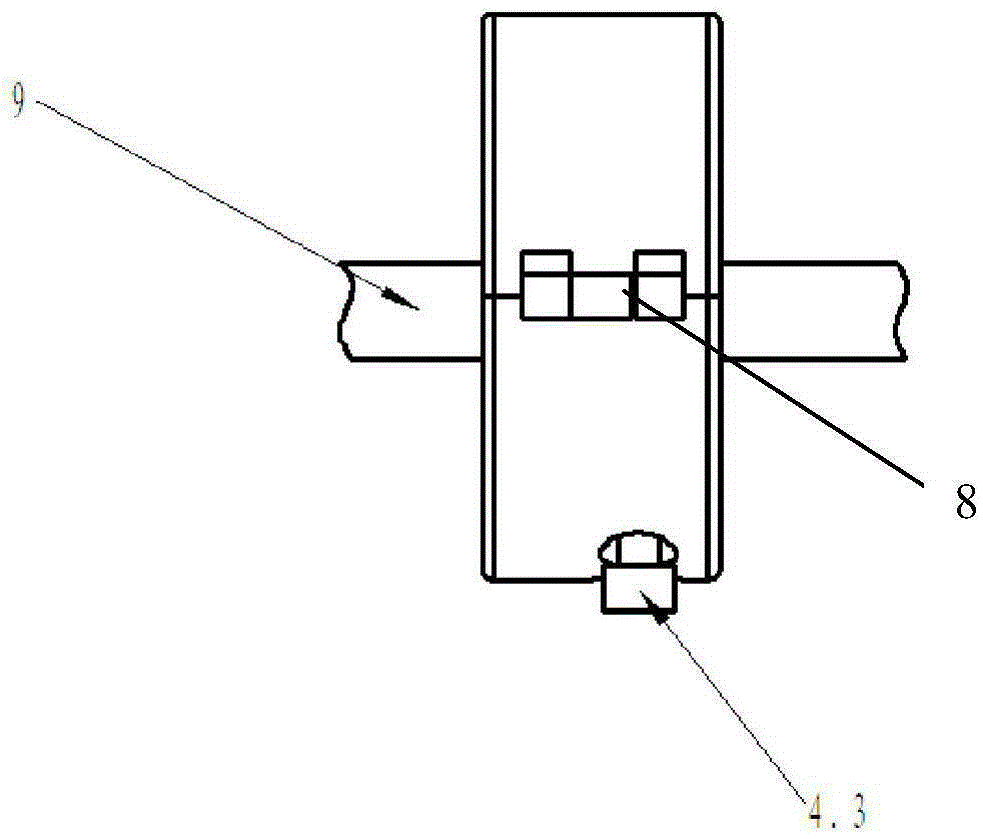

[0029] Such as Figure 1~6 As shown, it is an open current transformer that can be installed with electricity in the present invention, including a short cylindrical shell and a coil. In this embodiment, the coil is a complete circular flexible coil, specifically the flexible Rogowski coil 2, the flexible Rogowski coil 2 The coil 2 is a hollow coil that can be bent arbitrarily. It is embedded in the full circular shell formed by the moving half-ring shell 5 and the static half-ring shell 7 along the circumference, forming a secondary winding that is used as a primary winding relative to the primary busbar. . The side wall of the casing is a double-layer structure to form an annular cavity for containing the coil, and the casing is divided into two butt-joint semi-cylindrical bodies as the dynamic half-ring shell 5 and the static half-ring shell 7, and the moving half-ring shell 5 and the static half-ring shell The housing 7 is hingedly connected at one of the butt joints, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com