Array substrate and preparation method thereof and display device

A technology for array substrates and display areas, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems that the lead area cannot emit light, the display panel cannot be narrowed, and the black area of the screen cannot be displayed. , to achieve the effect of easy operation, narrow frame and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

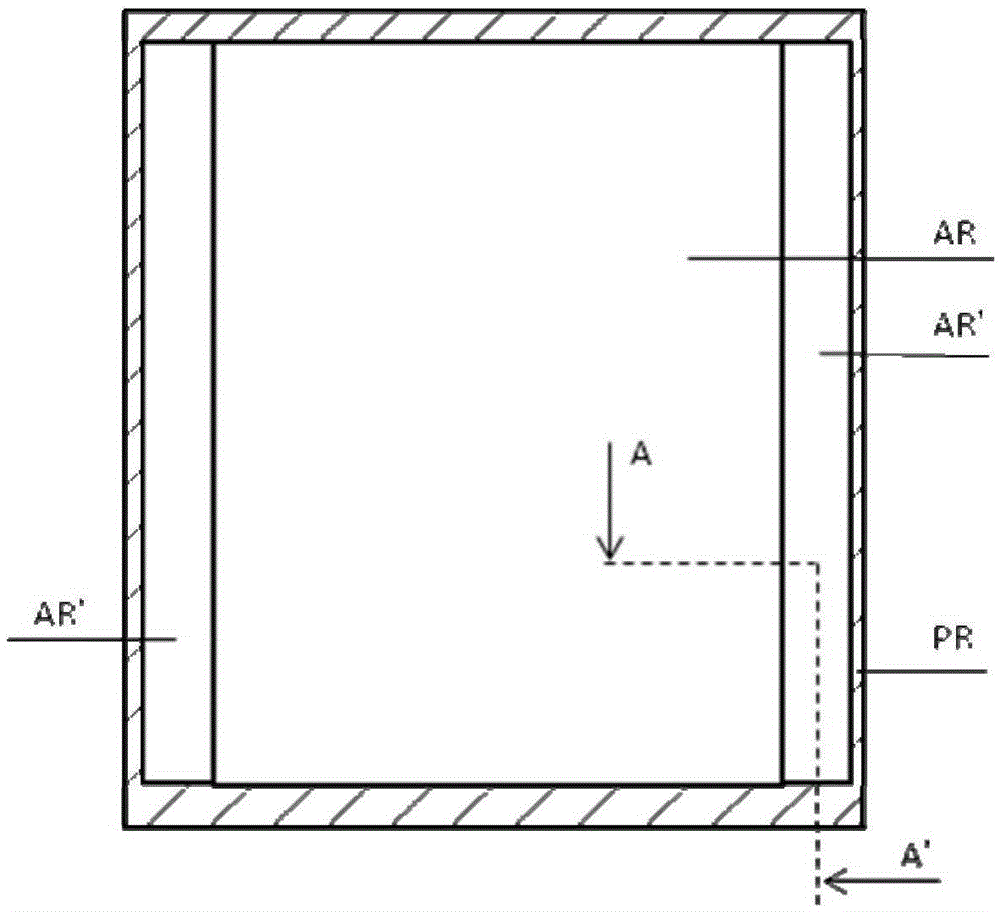

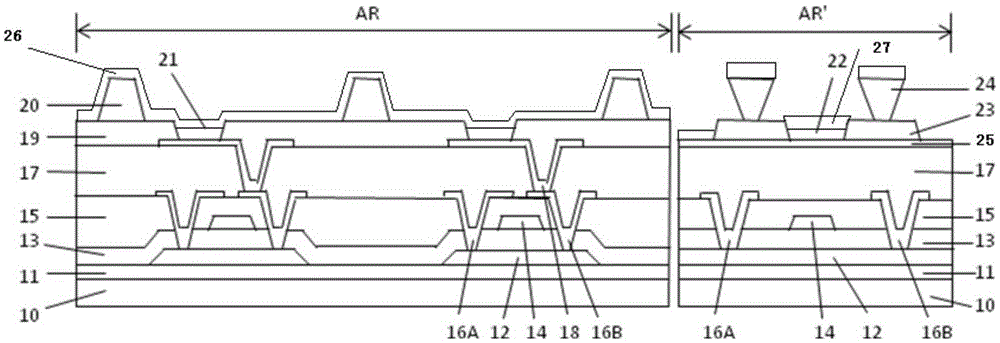

[0048] Such as figure 1 with 2As shown, this embodiment provides an array substrate, including a display area AR and a peripheral area AR' surrounding the display area AR (wherein PR shown in the figure is the entire non-display area), and in the display area AR A plurality of active organic electroluminescent diodes are provided, and a plurality of passive organic electroluminescent diodes are arranged in the peripheral area AR'; wherein, the active organic electroluminescent diodes and the passive organic electroluminescent diodes are both connected to The power drive unit is electrically connected.

[0049] Specifically, those skilled in the art can understand that the array substrate includes a substrate 10, a plurality of gate lines and a plurality of data lines intersecting and insulated on the substrate, wherein the positions where adjacent gate lines and adjacent data lines intersect A pixel will be defined, and each pixel includes a light-emitting element and a swit...

Embodiment 2

[0058] to combine Figure 2-6 This embodiment provides a method for preparing an array substrate, wherein the array substrate may be the array substrate in Embodiment 1, and the preparation method of this embodiment specifically includes the following steps:

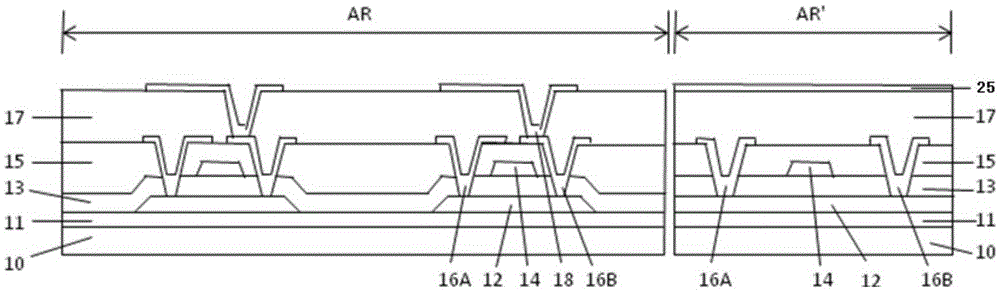

[0059] Step 1: Deposit the buffer layer 11 and the active layer thin film in sequence on the substrate, and use patterning technology to form the pattern of the active layer 12 including the switching transistor in the display area AR', and form each of the gate drive circuits in the peripheral area AR' The pattern of the active layer 12 of the transistor. Then, a gate insulating layer 13 is formed on the substrate on which the active layer is formed.

[0060] Wherein, the materials of the buffer layer 11 and the gate insulating layer 13 can be silicon oxide (SiOx), silicon nitride (SiNx), hafnium oxide (HfOx), silicon oxynitride (SiOxNy), aluminum Oxide (AlOx), etc. or a multilayer film composed of two or three of the...

Embodiment 3

[0083] This embodiment provides a display device, which includes the array substrate of Embodiment 1. The display device can be any product or component with a display function such as an OLED panel, a mobile phone, a tablet computer, a TV set, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com