Comb-shaped flexible electrode and battery employing comb-shaped flexible electrode

A flexible battery and flexible electrode technology, applied in the direction of active material electrodes, battery electrodes, circuits, etc., can solve the problems of battery flexibility and achieve the effects of enhanced flexibility, simple manufacture, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

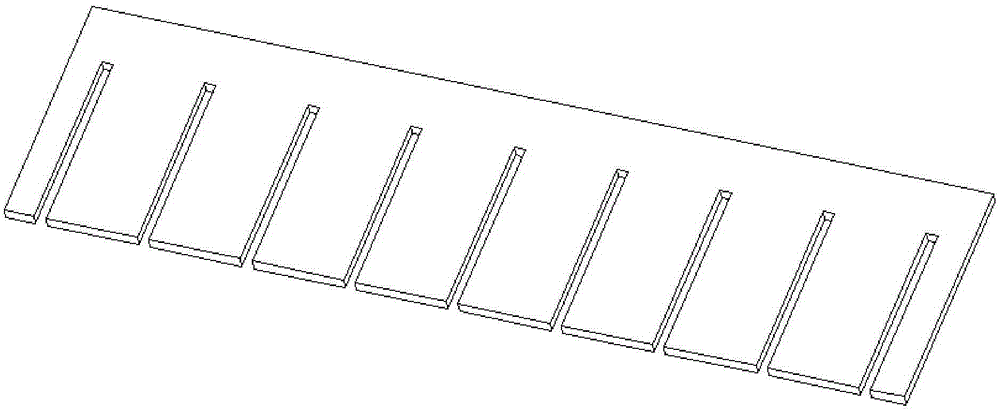

[0030] Such as figure 1 As shown, a comb-shaped flexible electrode includes a conductive substrate, the conductive substrate is coated with an active material layer, and the conductive substrate coated with the active material layer is cut into a comb-shaped structure.

[0031] Comb teeth or comb teeth are square, rectangular, circular, rhombus, zigzag, wavy or oval. Not shown in the figure.

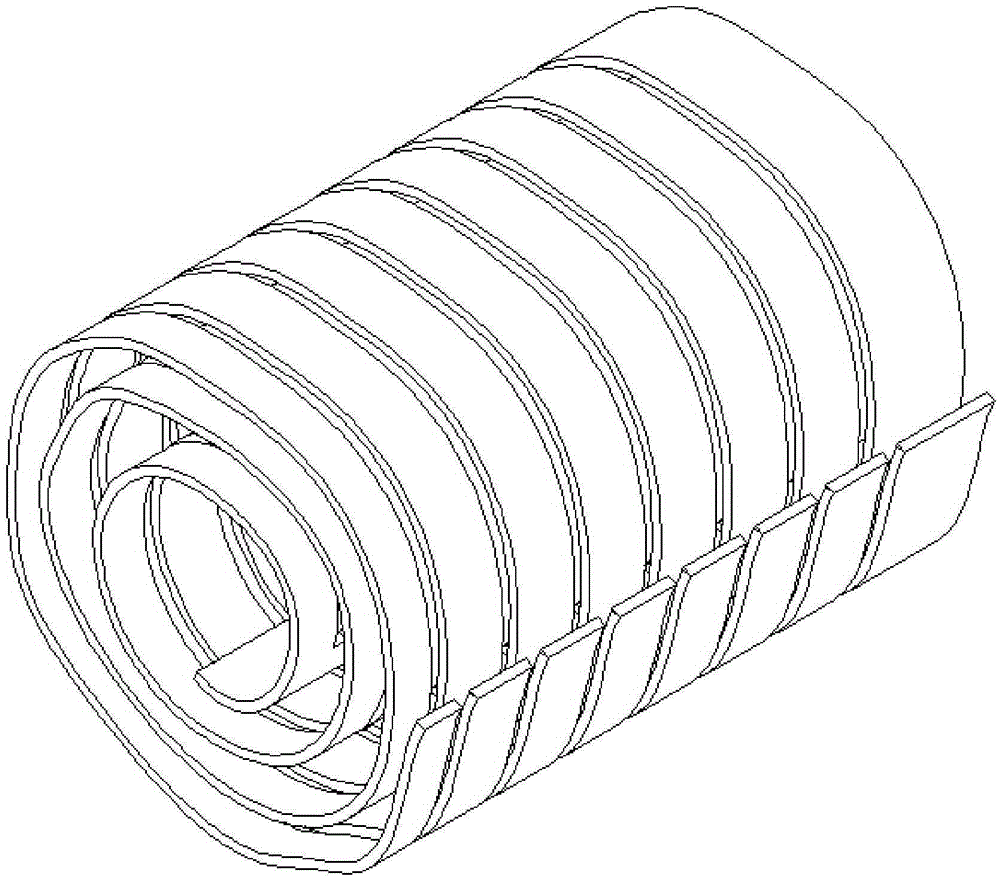

[0032] A battery comprising the comb-shaped flexible electrodes described above. Not shown in the figure.

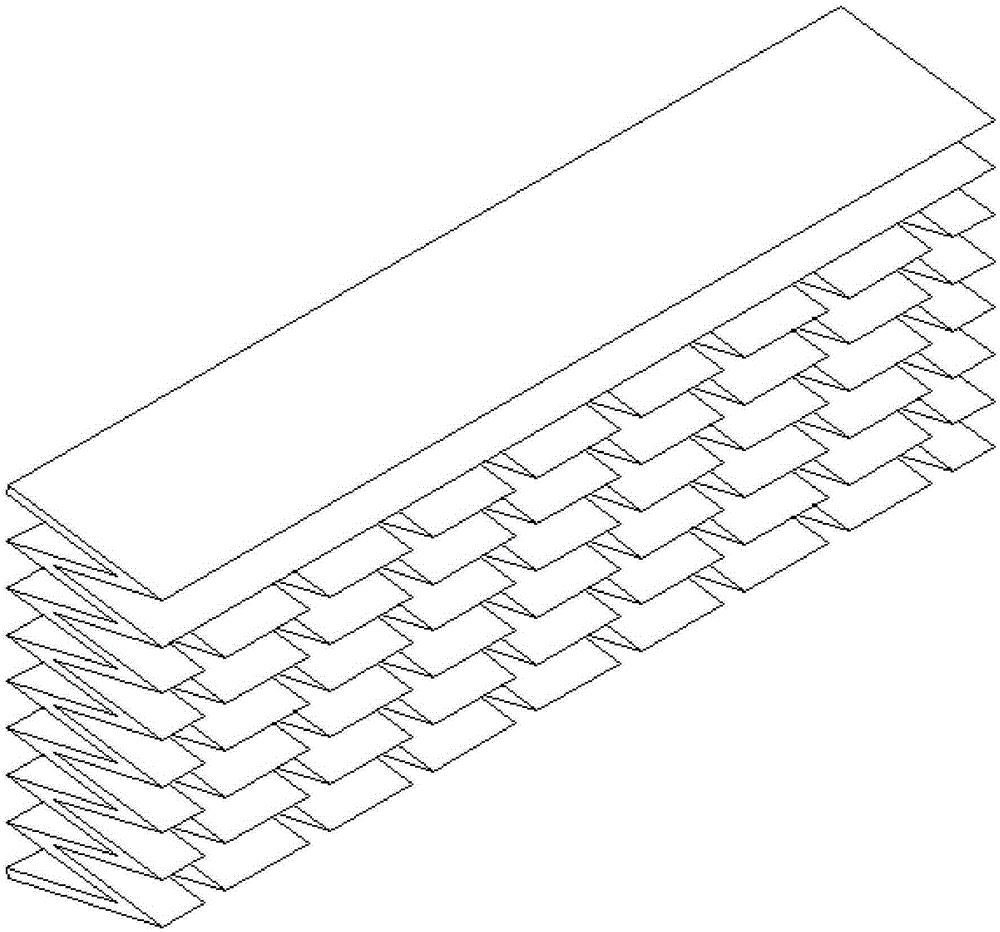

[0033] The battery is a laminated structure: it includes a flexible battery casing, a battery body located in the flexible battery casing, and an electrolyte poured into the flexible batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com