Blower

一种送风机、风扇的技术,应用在机械设备、机器/发动机、液体燃料发动机等方向,能够解决价格高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] One embodiment of the present invention will be described.

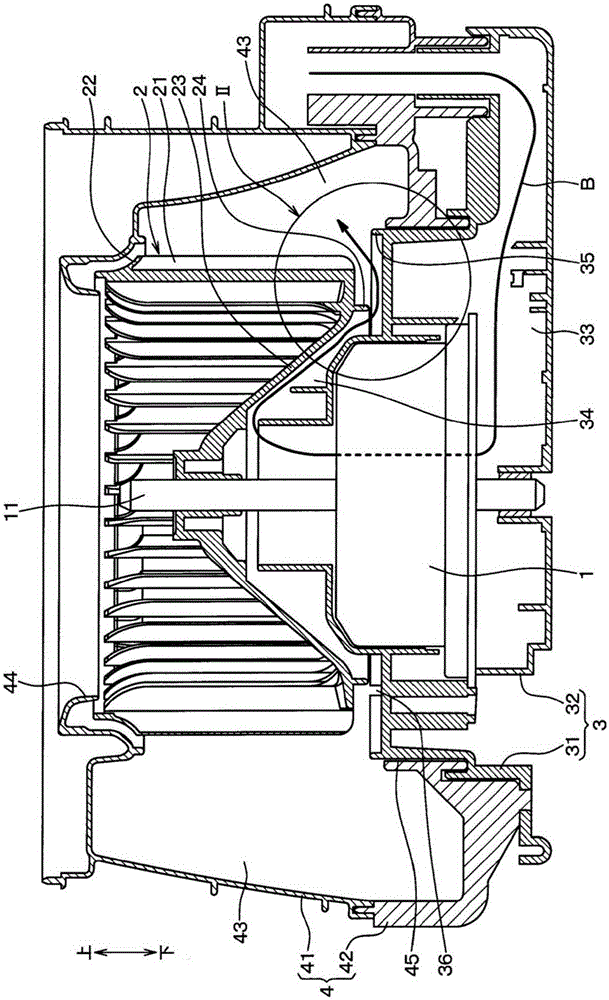

[0019] Such as figure 1 As shown, the air blower includes: a motor 1 having copper brushes; a resin fan 2 that blows air by rotating the motor 1; a resin motor case 3 that accommodates the motor 1; and a resin housing 3 that accommodates the fan 2. Made fan housing 4. In addition, below, the axial direction of the rotating shaft 11 of the electric motor 1 is called a rotating axial direction.

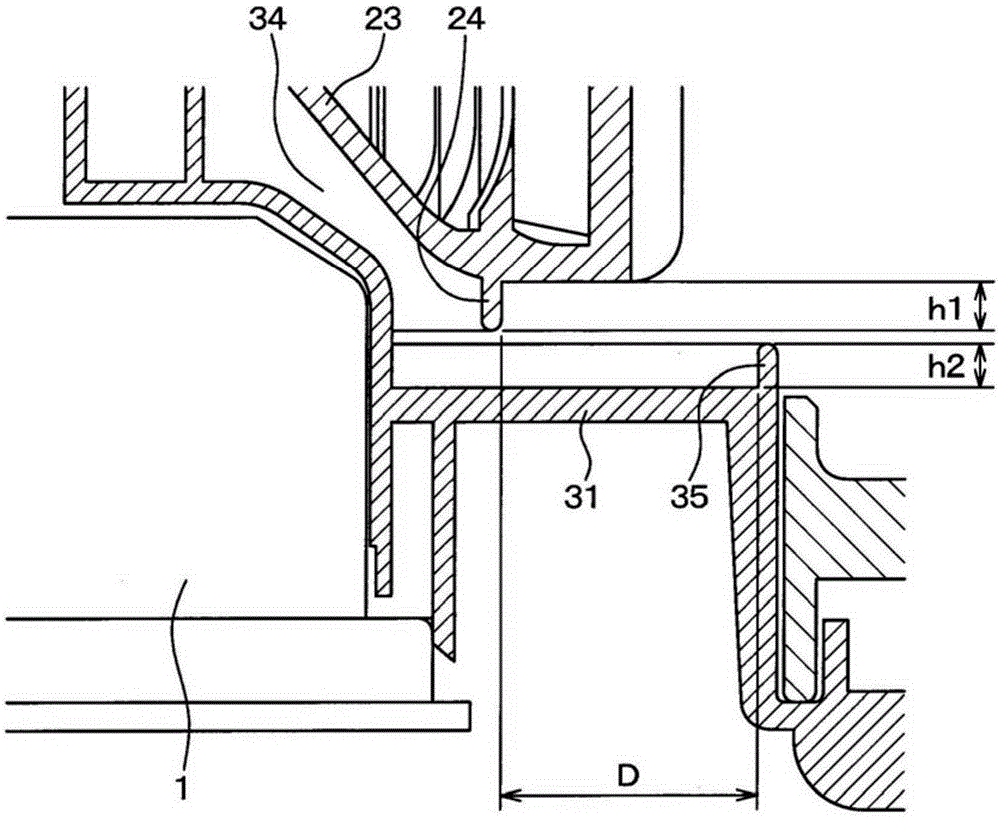

[0020] The fan 2 is provided with a plurality of plate-shaped blades 21 around the rotating shaft 11 . One end side of the blade 21 in the rotational axis, that is, an end portion on the suction port 44 side described later is connected by an annular side plate 22 . In addition, the other end of the blade 21 in the rotational axis is connected by a main plate 23 .

[0021] The main plate 23 has a substantially conical shape in which one end side in the rotational axis, that is, the side plate 22 side protrudes. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com