Inverted umbrella type forest fruit vibration harvesting mechanism

A form and umbrella-shaped technology, which is applied in the field of the inverted umbrella-shaped fruit vibration harvesting mechanism, can solve the problems such as being unsuitable for fruit harvesting in orchards, and achieve the effects of reducing harvesting costs, simple operation and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

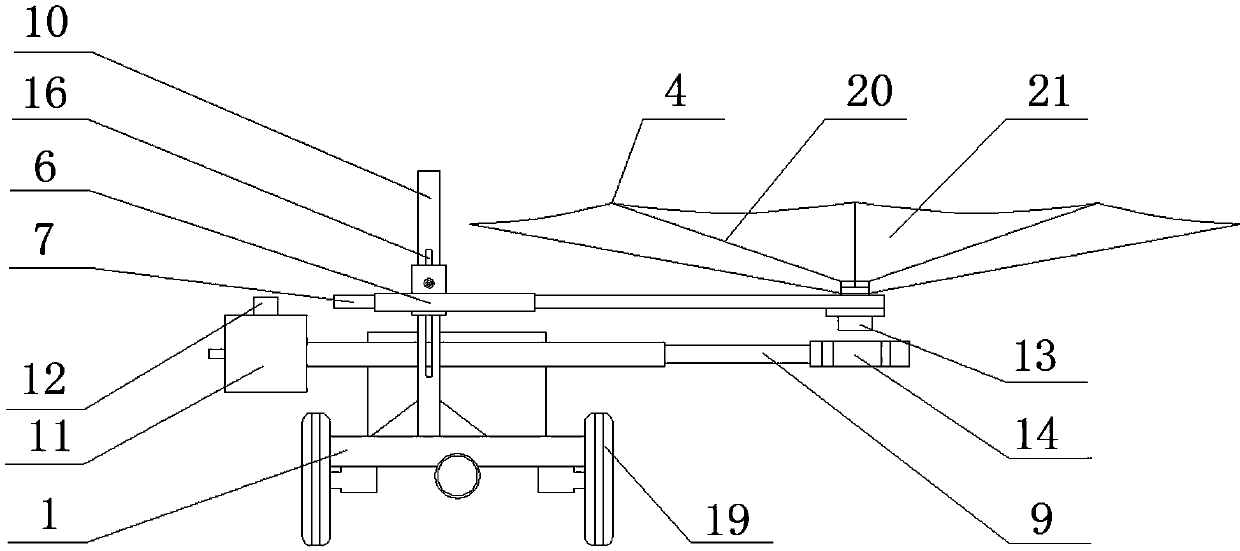

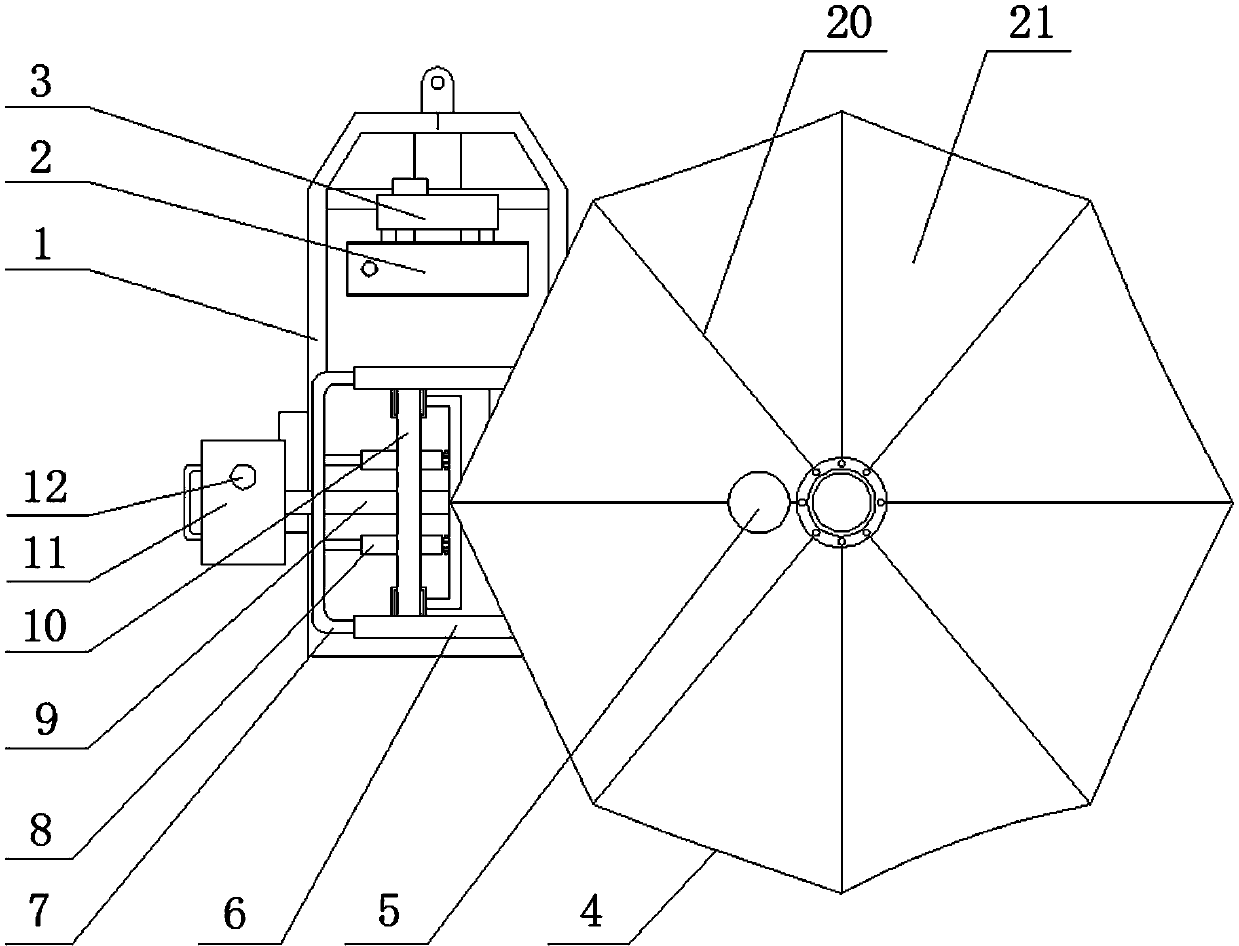

[0025] Such as figure 1 , figure 2 As shown, the inverted umbrella form fruit vibration harvesting mechanism includes a traction chassis 1, a walking wheel 19, a power transmission device 3, a hydraulic control system 2, a harvesting fixed frame 10, a vibrating box 11, a vibrating clamping cantilever 9, and an inverted umbrella joint. The fruit mechanism 4 and the fruit frame 7 etc. are composed; the power transmission device 3 and the hydraulic control system 2 are installed on the front end of the traction chassis 1, and the harvesting fixed frame 10 is installed behind the hydraulic control system 2, and the harvesting fixed frame 10 is suspended in the center of the beam. Vibrating clamping cantilever 9, vibrating box 11 is arranged at the tail of vibrating clamping cantilever 9, clamping device 14 is set at the front end of vibrating clamping cantilever 9, hydraulic motor 12 and eccentric vibrating block are housed in vibrating box 11, vibration clamping cantilever 9 Th...

Embodiment 2

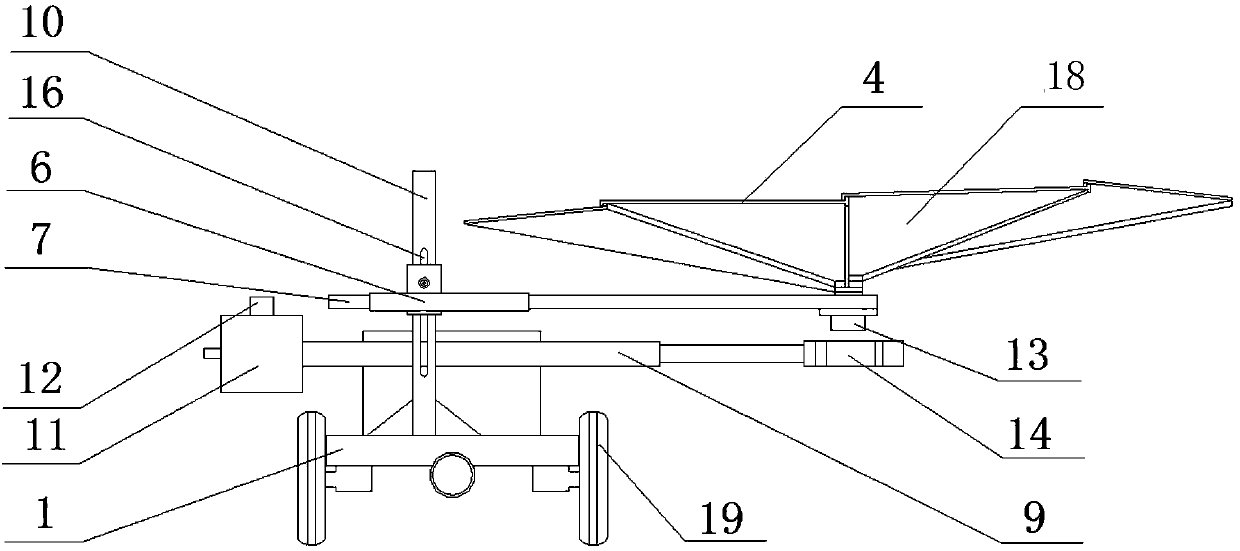

[0027] Such as image 3 , Figure 4 As shown, the inverted umbrella form fruit vibration harvesting mechanism includes a traction chassis 1, a walking wheel 15, a power transmission device 3, a hydraulic control system 2, a harvesting fixed frame 10, a vibrating box 11, a vibrating clamping cantilever 9, and an inverted umbrella joint. The fruit mechanism 4 and the fruit frame 7 etc. are composed; the power transmission device 3 and the hydraulic control system 2 are installed on the front end of the traction chassis 1, and the harvesting fixed frame 10 is installed behind the hydraulic control system 2, and the harvesting fixed frame 10 is suspended in the center of the beam. Next to the vibrating box 11 and the vibrating clamping cantilever 9, the vibrating box 11 is equipped with a hydraulic motor 12 and an eccentric vibrating block. The column is vertical, the sliding fixed frame 6 is fixedly connected with the harvesting fixed frame 10, the fruit receiving frame 7 is adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com