Dry fruit high-pressure spray cleaning machine

A high-pressure spraying and washing machine technology, applied in application, food processing, food science and other directions, can solve the problems of low cleaning efficiency and poor cleaning effect, and achieve the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

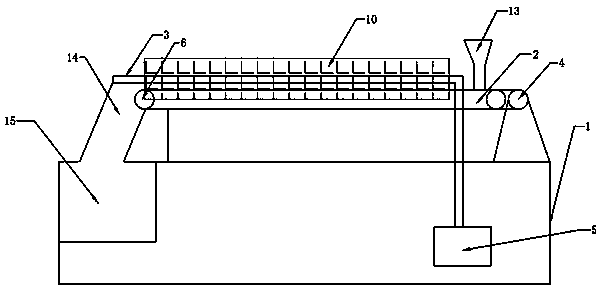

[0017] Such as figure 1 Shown, the present invention is a kind of dried fruit high-pressure spray cleaning machine, comprises frame 1, and conveying device 2 installed on frame 1, opposite spraying device 3, one-way motor 4 and water tank 5; The roller conveyor 6 linked with the one-way motor 4 and the wide belt 7 installed on the roller conveyor 6, and the wide belt 7 is provided with pushing rods 8 at intervals;

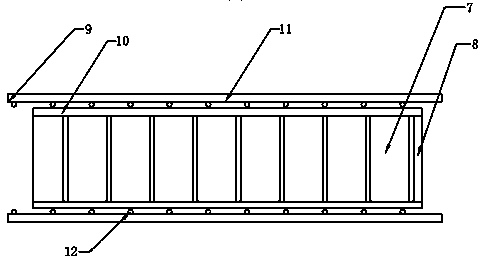

[0018] The spraying device 3 includes a left and right spraying device 9 and left and right blocking grids 10 respectively arranged on both sides of the wide belt 7, and the left and right spraying device 9 includes a spray pipe 11 communicated with the water tank 5 and a shower nozzle located on the spray pipe 11 12. The spray pipes 11 are installed outside the left and right blocking grids 10, and the nozzles 12 of the left and right spraying devices 9 are alternately arranged on the left and right; the distance between the left and right blocking grids 10 is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com