Entrainment capturing device and preparation process thereof

A technology of capturing device and manufacturing process, applied in the field of gas-liquid separation device, can solve the problems of complex structure, difficult manufacturing, easy damage, etc., and achieve the effects of high precision, difficult modification and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

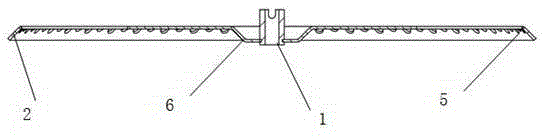

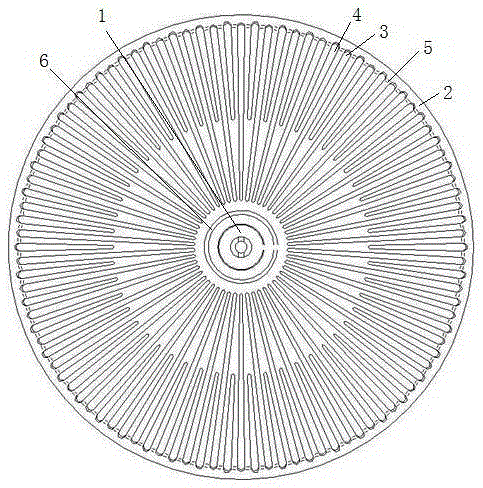

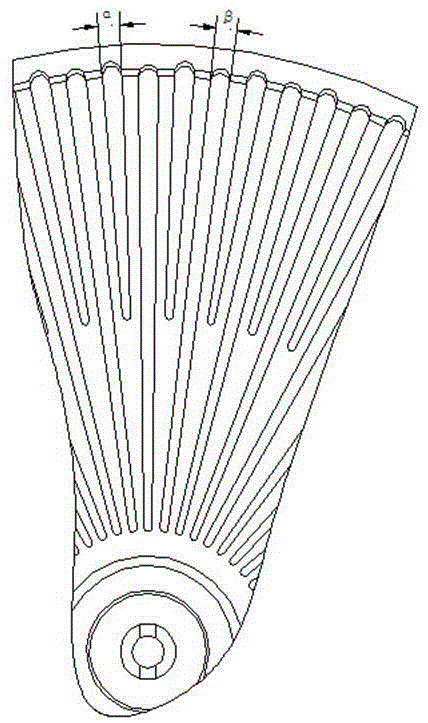

[0057] Such as figure 1 As shown, the outer diameter of the separation disc is: φ300mm; there are 50 long fan-shaped holes and 50 small fan-shaped holes on the disc surface; the total area of the separation disc openings: S=0.0617m 2 ;Separation disc thickness: δ=2 mm; Set the speed of the separation disc: n=1450 rpm; Set the wind speed: Q=5 meters3 / sec; yields:

[0058] α≤3nδS / 50Q;

[0059] α≤(3×1450×2×0.0617) / (50×5);

[0060] α≤2.15 degrees;

[0061] Similarly: β≤2.15 degrees;

[0062] That is, the side angle of the fan-shaped hole is less than or equal to 2.15 degrees; from the calculation process, it can be seen that the higher the rotation speed of the separation disc, the greater the gas processing capacity, but it will cause an increase in noise. The larger the total opening area, the larger the gas handling capacity, but the width of the ribs will become smaller and the strength will decrease.

[0063] 2) Press the disc made in step (1) through a stretch formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com