Mosquito-resisting PVC coating film material and coating knife-scraping process thereof

An anti-mosquito and coating film technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of erosion of the coating film material, discoloration of appearance, aging and scrapping of the film material, etc., to achieve low construction cost, production The effect of simple equipment and human safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of anti-mosquito PVC coating membrane material, comprises base cloth layer, is coated with first base coat on the front of base cloth layer, is coated with second base coat on the back side of base cloth layer, is coated with the first base coat The surface is coated with a first anti-mosquito coating, and the surface of the second base coat is coated with a second anti-mosquito coating; the base cloth layer is composed of base cloth. Both the first primer layer and the second primer layer are polyvinyl chloride paste resin layers, and the polyvinyl chloride paste resin layer is formed by scraping polyvinyl chloride paste resin doped with an adhesive. The polyvinyl chloride paste resin with a K value of 75 is selected as the vinyl paste resin, Lanxess (Lanxess) 2001 is selected as the adhesive, and the ratio of the amount of the adhesive to the polyvinyl chloride paste resin is 3:100.

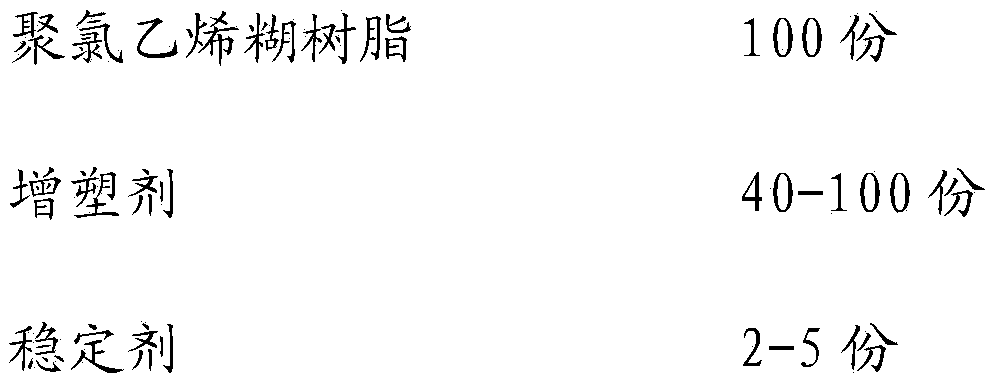

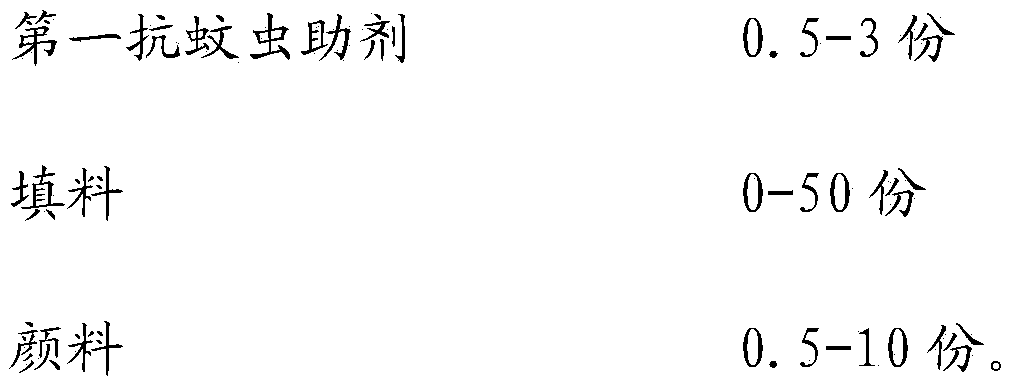

[0042] Wherein, the formula of anti-mosquito PVC paste resin slurry is as fol...

Embodiment 2-10

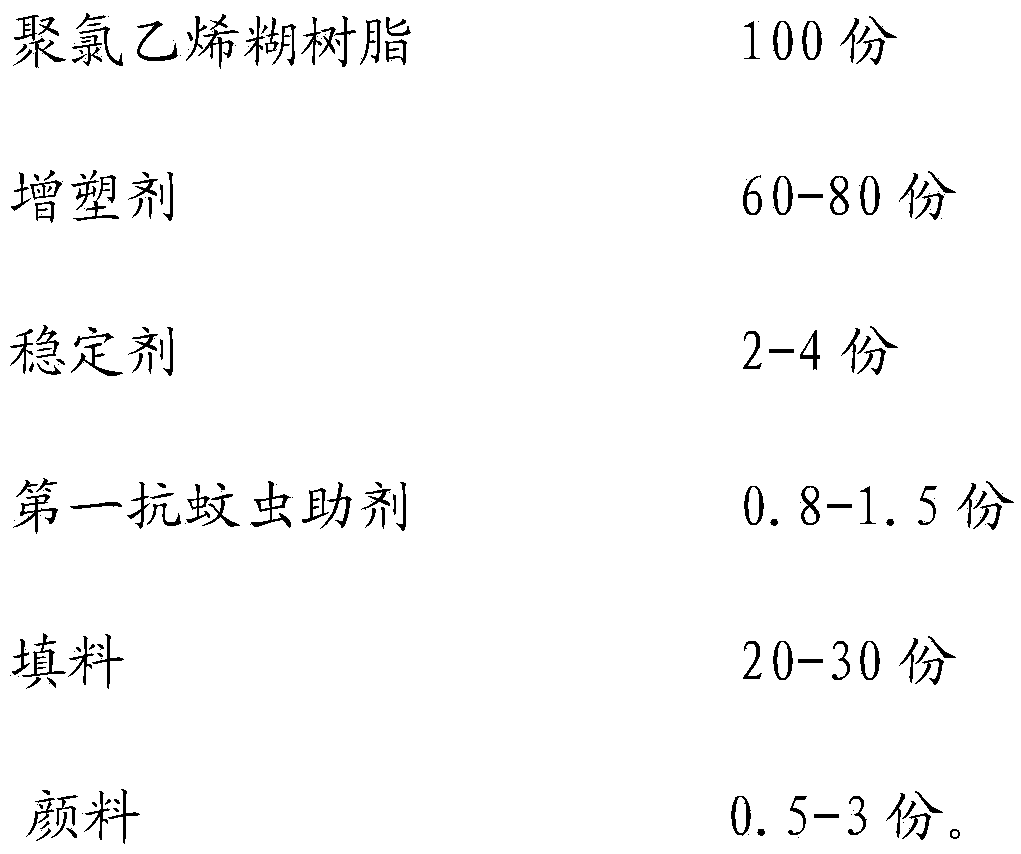

[0052] Weigh the raw materials according to the ratio in Table 3 respectively, and prepare according to the steps in Example 1. The difference is that the ratio of raw materials added is different, and the product is prepared. For details, see the anti-mosquito PVC paste resin slurry in Table 3. The formula dosage of the material:

[0053] The formula of the anti-mosquito PVC paste resin slurry of table 3 embodiment 2-10

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com