Welding equipment and combined welding method for combined welding

A technology of welding equipment and welding method, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult operation, inconsistent pressing force, and low efficiency of the method, so as to improve welding quality and ensure Welding precision, achieve the effect of repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

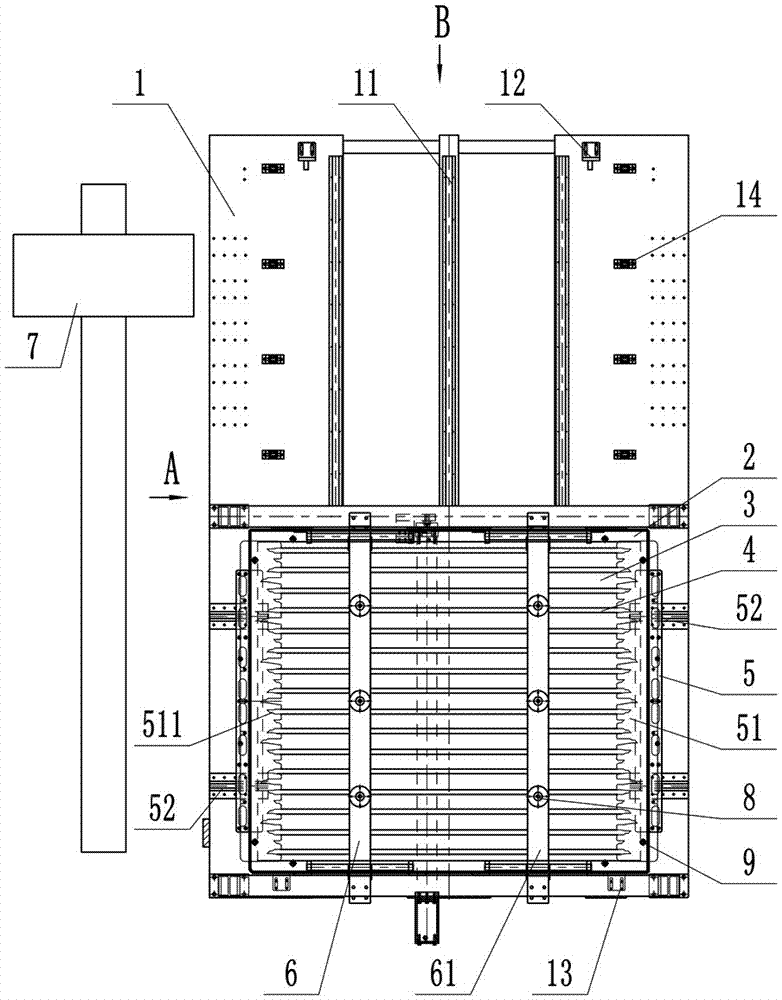

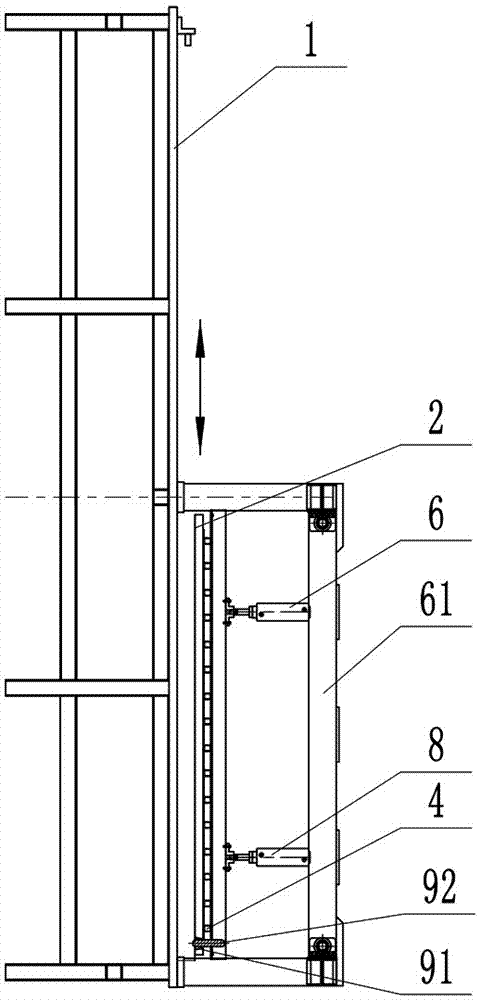

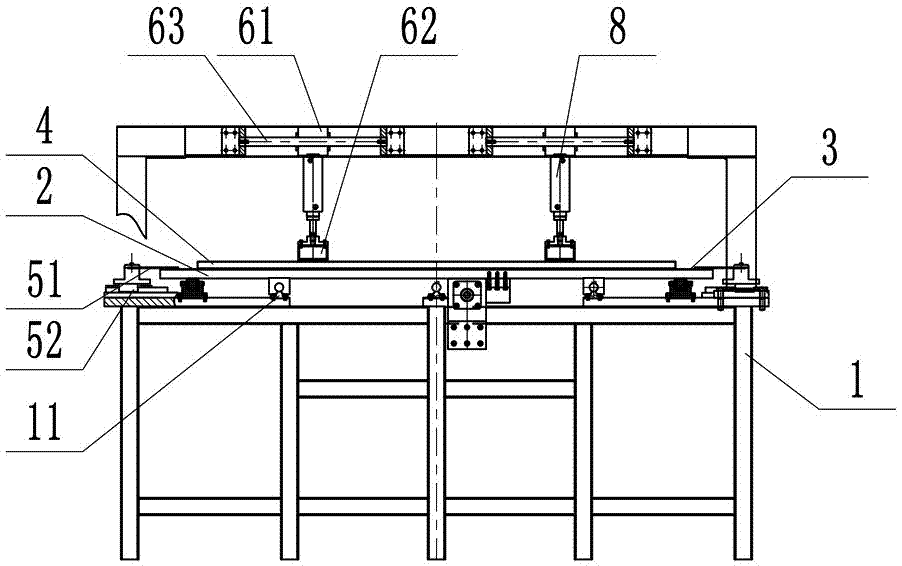

[0030] like Figure 1 to Figure 3 As shown, the welding equipment used for combined welding in this embodiment includes a machine bed 1 and a working platform 2. The working platform 2 is arranged on the machine bed 1, and the working platform 2 is used to place the base material 3. In this embodiment The welding equipment used for combined welding also includes a base metal positioning assembly 9, a sub-piece positioning assembly 5 and a pressing assembly 6. Part 4, the pressing assembly 6 presses the positioned sub-part 4 on the base material 3. The setting of the base material positioning assembly 9 and the sub-piece positioning assembly 5 effectively avoids the relative movement between the base material 3 and the sub-piece 4, and effectively realizes the reliable positioning of the sub-piece 4; the pressing assembly 6 compresses the sub-piece 4 on the The base material 3 avoids gaps between the sub-parts 4 and the base material 3, effectively improving the welding qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com