A cylinder processing fixture

A technology for fixing devices and cylinders, applied in positioning devices, clamping devices, metal processing equipment, etc., can solve problems such as cumbersome operation, insufficient pressing force, and processing defects, so as to improve processing efficiency, increase pressing force, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

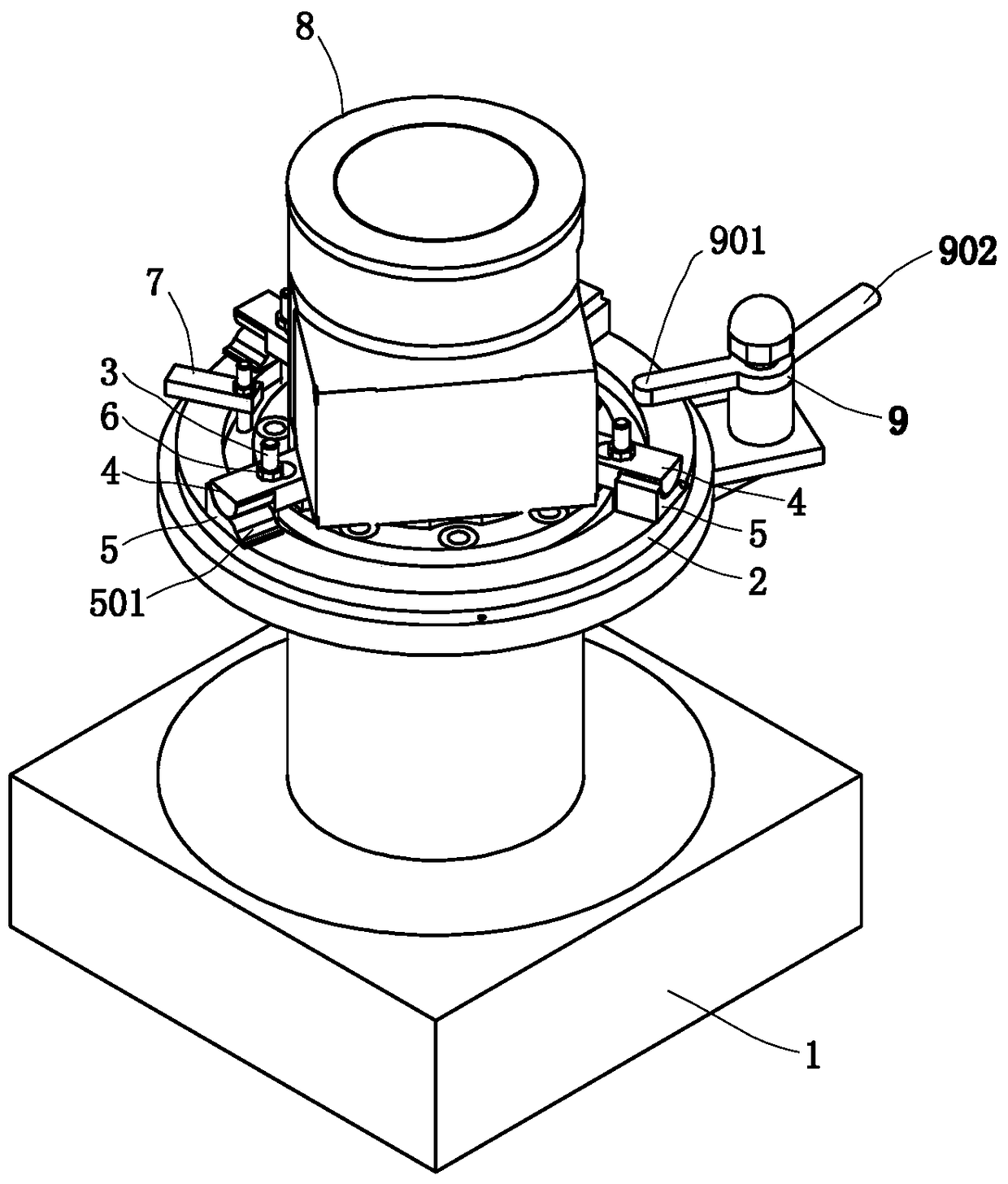

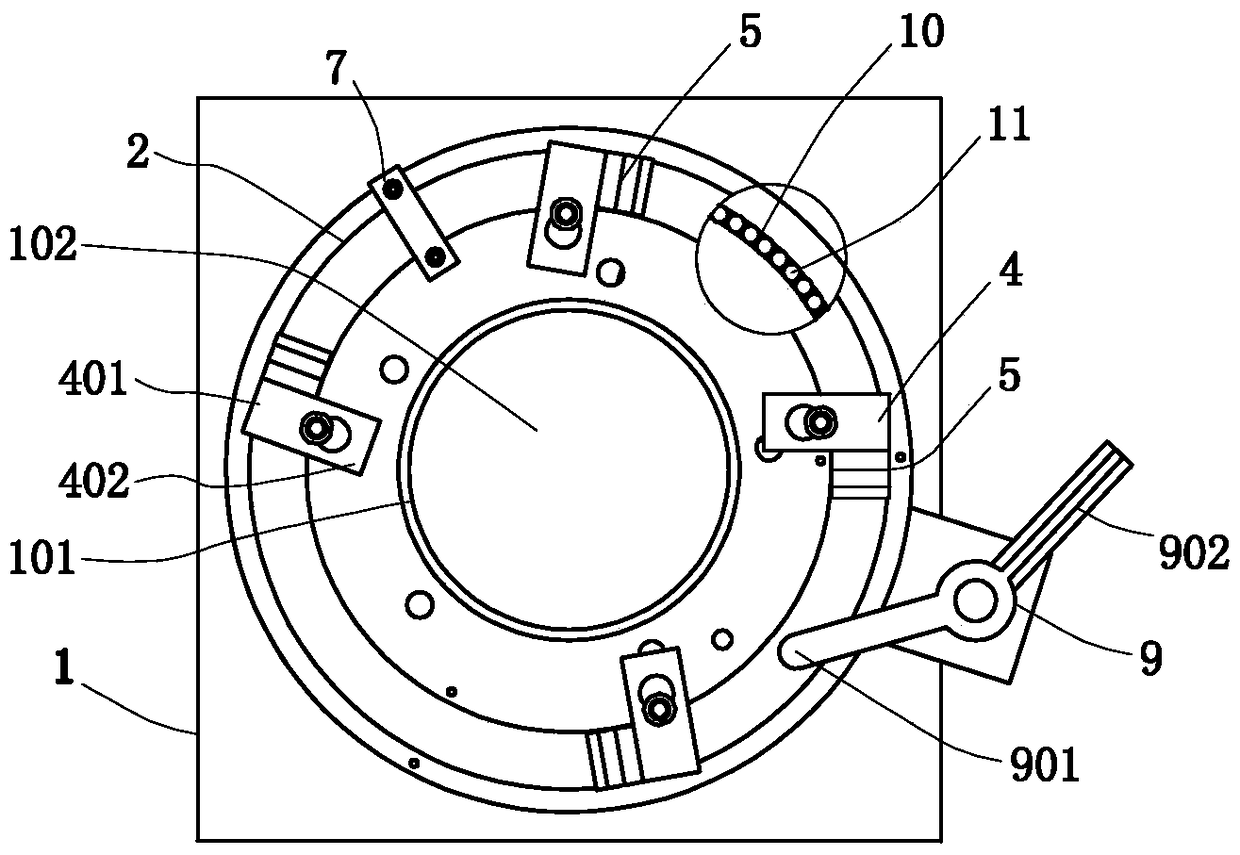

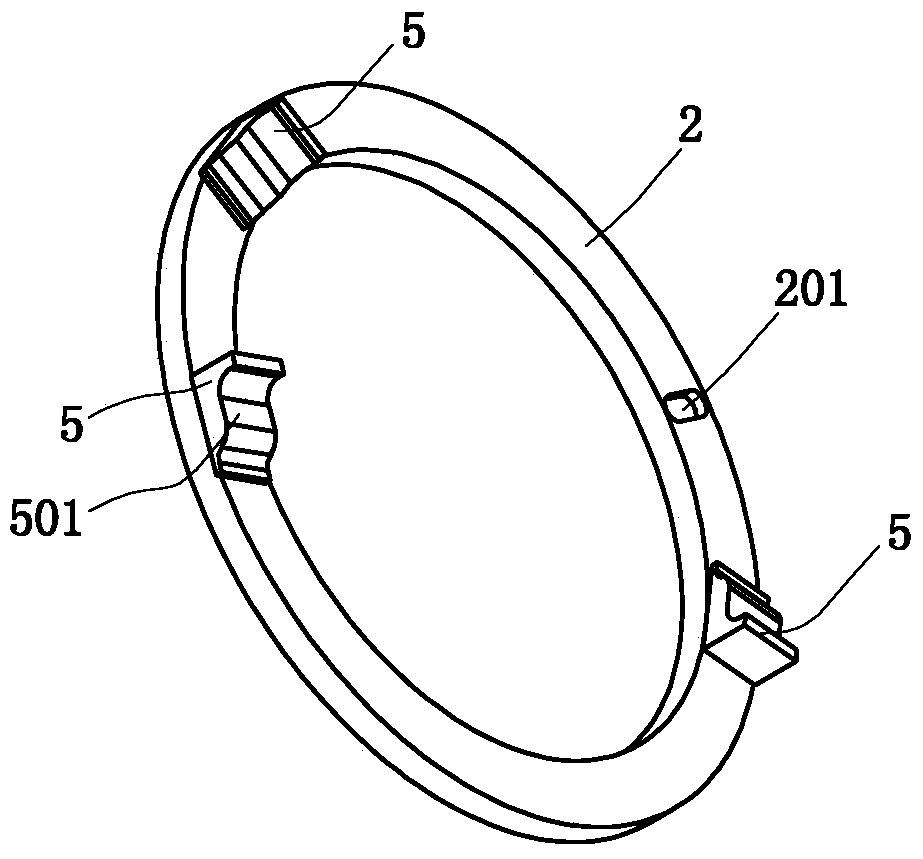

Embodiment 1

[0025] Such as Figure 1 to Figure 3 Commonly shown, the present invention provides a cylinder processing fixture, including a support base 1, the top of the support base 1 is provided with a limit groove 101 that matches the end of the outer flange of the rotary workpiece 8, directly The end of the outer flange of the rotary workpiece 8 is placed in the limit groove 101, which realizes fast alignment and positioning. A swivel 2 is installed on the outer circumference of the limit groove 101 on the support seat 1, and the swivel 2 is connected to the rotary There are a number of fixed shafts 3 fixedly installed on the support base 1 between the workpieces 8, and a pressing block 4 is constrained to be installed on each fixed shaft 3. As for the connection method between the pressing block 4 and the fixed shaft 3, specifically, it can be used In the following structure, the pressing block 4 is provided with a through hole, the fixed shaft 3 passes through the through hole and t...

Embodiment 2

[0031] The present invention provides a cylinder processing and fixing device, the structure of which is basically the same as that of Embodiment 1, the difference being that: the power device includes a driving gear driven by a motor, and a ring gear meshing with the driving gear is provided on the swivel 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com