Manufacturing technology for medicine wooden door

A production process and technology for wooden doors, which are applied in the field of pharmaceutical wooden doors, can solve the problems of inability to assist pneumonia treatment, and the wooden doors do not have the ability to distribute drugs, and achieve the effect of small lines and hard density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

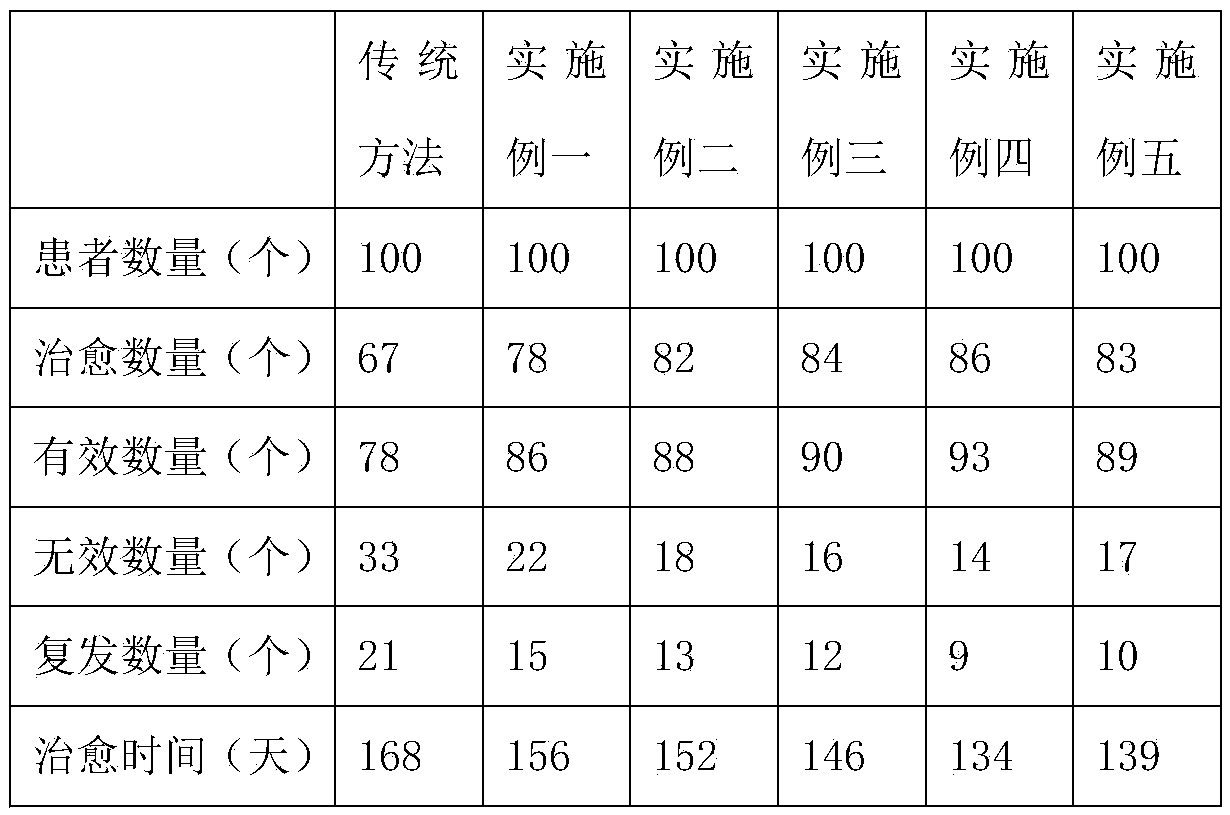

Examples

Embodiment 1

[0046] Embodiment one: the manufacturing process of medicine wooden door, comprises the following steps:

[0047] A: Timber selection: The sand path of the selected wood should be fine, the grain small, the density of the wood is hard, and it is not easy to deform or crack after drying;

[0048] B: wood soaking: prepare the water tank, add 2000kg of water into the water tank, then add mixed Chinese medicine to the water for soaking, and the soaking time is 1h. Mangosteen 30kg, mulberry leaf 13kg, loquat leaf 10kg, wood butterfly 11kg, melon 11kg, lily 16kg, honeysuckle 25kg, dandelion 15kg, rhizoma rhizome 20kg, wild chrysanthemum 12kg, hundred 6kg, licorice 10kg, lentils 23kg, fungus 17kg; then Put a high fire into the bottom of the water tank to boil the water, keep it for 15 minutes, then adjust it to a simmer, boil the mixed Chinese medicine, keep it for 2 hours, then turn it down to a low fire, keep the temperature, and saw the selected wood with a chainsaw to a thickness...

Embodiment 2

[0053] Embodiment two: the manufacturing process of medicine wooden door, comprises the following steps:

[0054] A: Timber selection: The sand path of the selected wood should be fine, the grain small, the density of the wood is hard, and it is not easy to deform or crack after drying;

[0055] B: Wood soaking: Prepare the water tank, add 2100kg of water into the water tank, then add mixed Chinese medicine to the water for soaking, the soaking time is 1-2h, and the mixed Chinese medicine includes the following components: Shishanglian 38kg, Luo Han Guo 33kg, mulberry leaves 14kg, loquat leaves 13kg, wood butterfly 17kg, Trichosanthes 15kg, lily 19kg, honeysuckle 28kg, dandelion 17kg, Imperata 24kg, wild chrysanthemum 13kg, hundred 7kg, licorice 12kg, lentils 24kg, fungus 18kg; then Put a high fire into the bottom of the water tank to boil the water, keep it for 16 minutes, then adjust it to a simmer, boil the mixed Chinese medicine, keep it for 2.5 hours, then turn it down to...

Embodiment 3

[0060] Embodiment three: the manufacturing process of medicine wooden door, comprises the following steps:

[0061] A: Timber selection: The sand path of the selected wood should be fine, the grain small, the density of the wood is hard, and it is not easy to deform or crack after drying;

[0062] B: wood soaking: prepare a water tank, add 2200kg of water into the water tank, then add mixed Chinese medicine to the water for soaking, the soaking time is 1-2h, and the mixed Chinese medicine includes the following quality components: Shishanglian 39kg, Luo Han Guo 35kg, mulberry leaves 15kg, loquat leaves 21kg, wood butterflies 19kg, Trichosanthes 19kg, lily 22kg, honeysuckle 30kg, dandelion 19kg, Imperatae 26kg, wild chrysanthemum 15kg, hundred 8kg, licorice 14kg, lentils 15kg, fungus 20kg; then Put a high fire into the bottom of the water tank to boil the water, keep it for 17 minutes, then adjust it to a simmer, boil the mixed Chinese medicine, keep it for 3 hours, then turn i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com