Auxiliary adhesive tape packaging tool

A technology of auxiliary tooling and adhesive tape, applied in the direction of packaging, etc., can solve the problems of easily broken transparent plastic bags, time-consuming, manpower, waste of packaging materials, etc., and achieve the effect of convenient use, low cost, and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

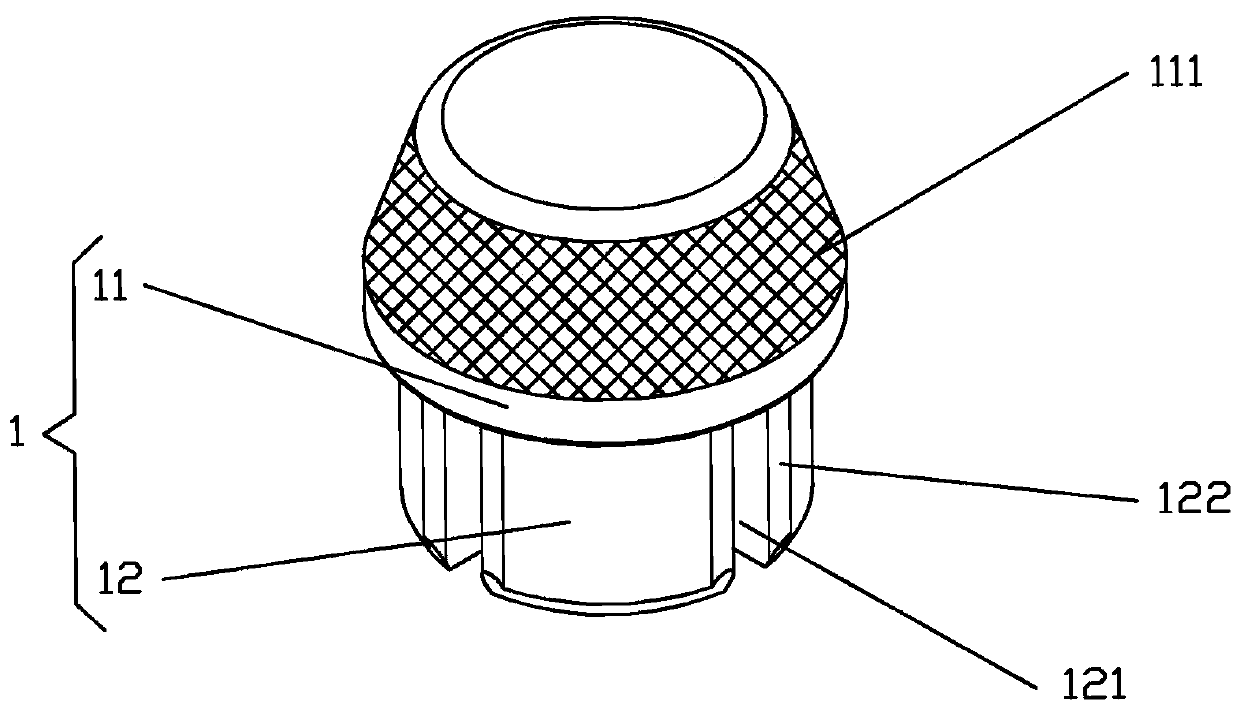

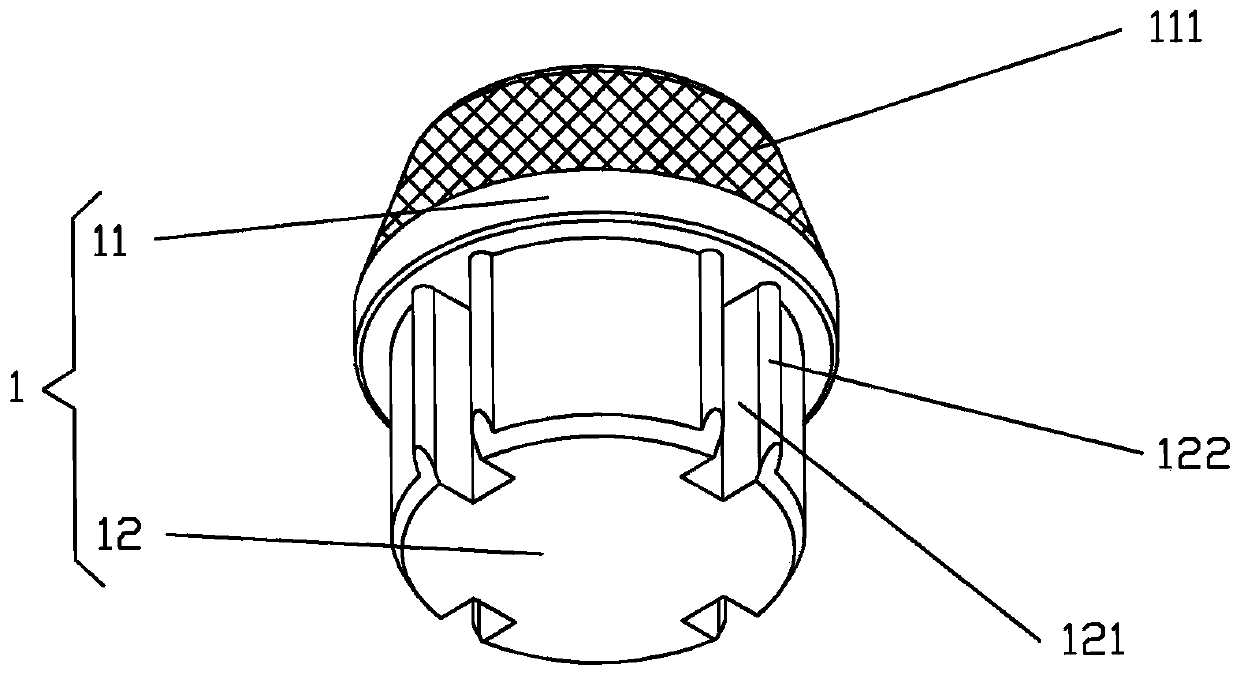

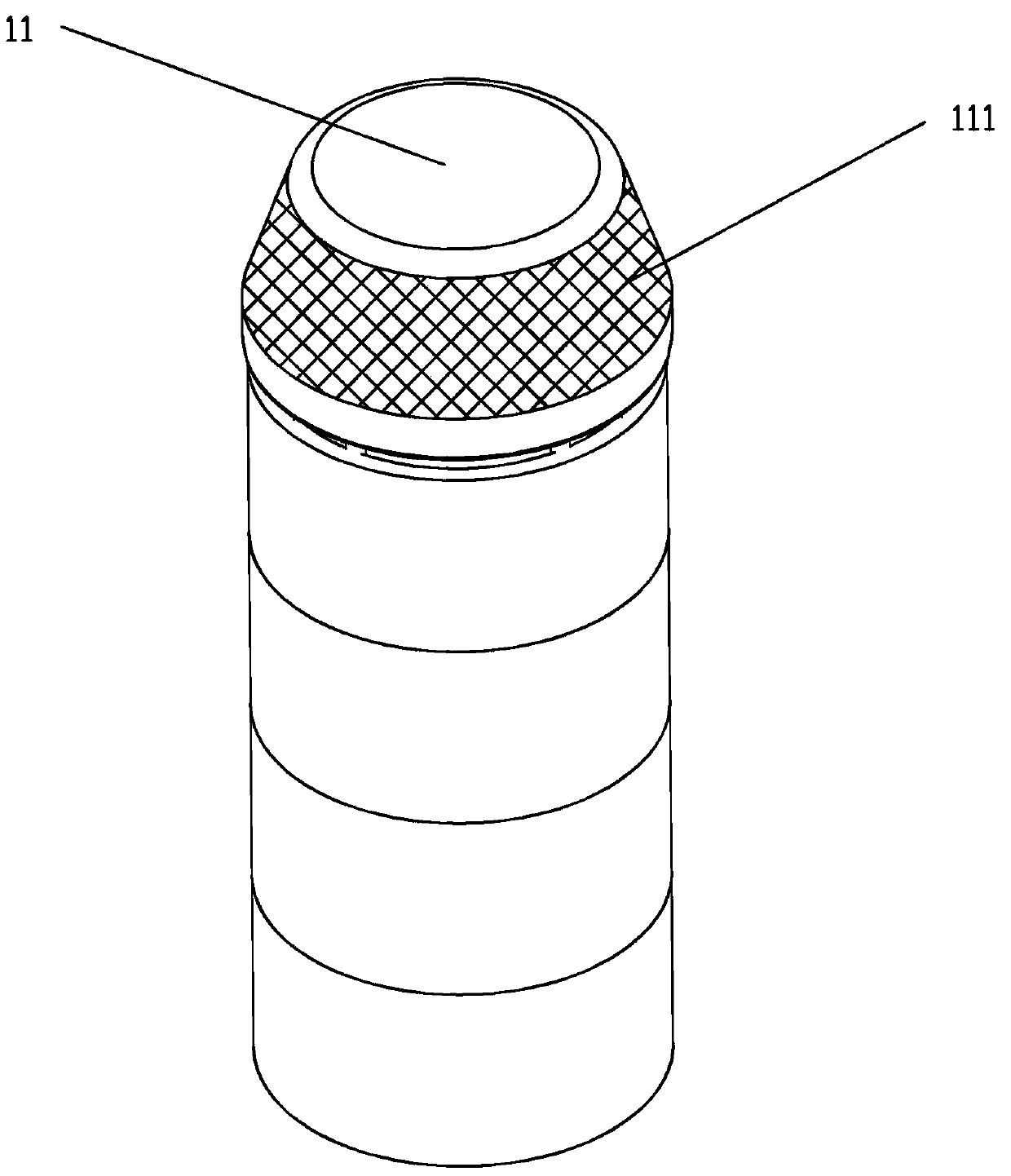

[0013] refer to Figure 1~Figure 3 , an auxiliary tool for tape packaging, including a body 1 made of plastic material, the body 1 includes a truncated cone-shaped upper guide part 11 and a lower installation part 12, the lower diameter of the guide part 11 is larger than the diameter of the outer surface of the tape 0.5mm to 1mm, guide lines 111 are provided on the side of the guide part 11, the installation part 12 is cylindrical and adapted to the inner surface of the adhesive tape, and the side of the installation part 12 is provided with circular uniform There are at least three vertical guide grooves 121 , and chamfers are provided on the upper edge of the guide part 11 and the lower edge of the installation part 12 . With the above-mentioned structure, when the tape is packaged, several tapes are stacked into a straight cylinder and the installation part 12 of the auxiliary tool is inserted into the tape at the upper end. The transparent plastic bag used for packaging i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com