Multi-stage filler constructed wetland construction method

A technology of artificial wetland and construction method, which is applied in the field of ecology and environmental protection, can solve the problems of combined use of multi-stage wetlands and low purification efficiency, and achieves the effect of avoiding wetland blockage and improving the level of reoxygenation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

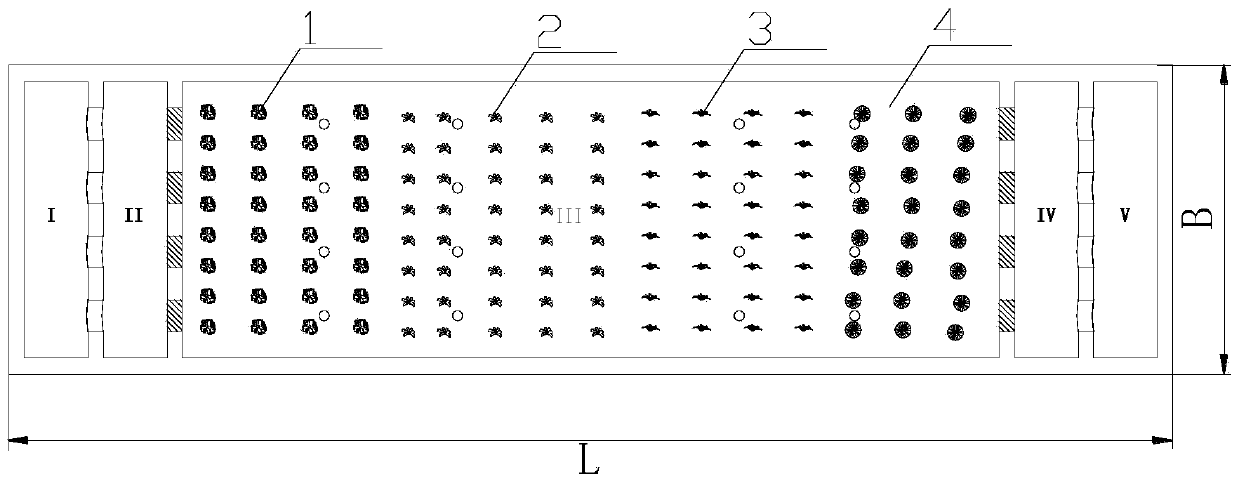

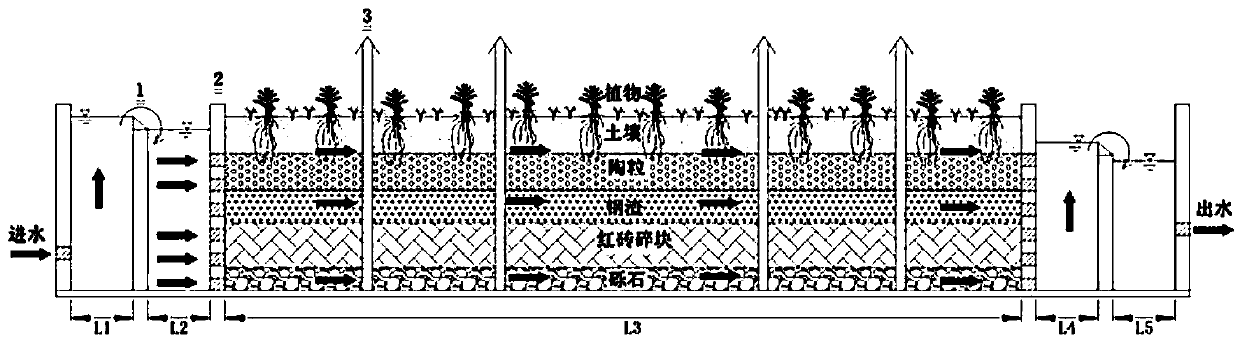

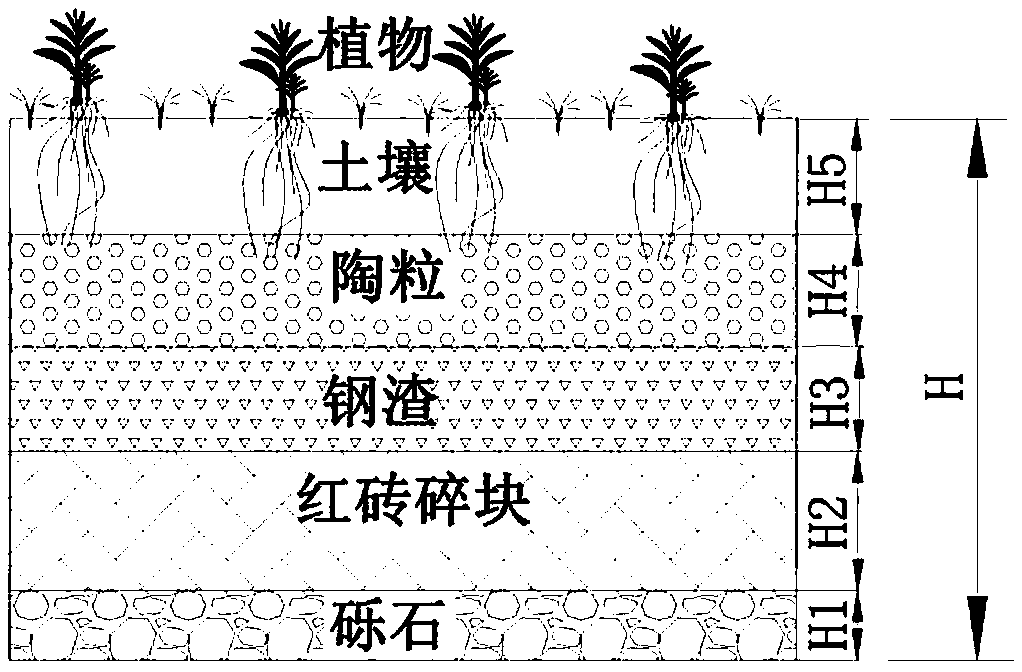

[0027] as attached figure 1 , attached figure 2 and attached image 3 As shown, the treated tail water volume is 12m 3 The overall specification of the multi-stage filler subsurface flow constructed wetland in / d is L×B×H=15.96m×3.74m×2.00m, which is divided into 5 areas, and a set of length L1=1.0m is built sequentially along the tailwater flow direction Pool I, water distribution tank II with length L2=1.0m, wetland bed area III with length L3=10m, sedimentation area IV with length L4=1.0m and clear water pool V with length L5=1.0m, the overall It is made of notoginseng wall bricks, and the water distribution tank and the sedimentation area are separated by two or four brick walls (small holes with a diameter of 20mm at a distance of 300mm are laid on the wall). The wetland bed area is sequentially filled with gravel with a particle size of 40-50 mm and a thickness of H1 = 26 cm, red brick fragments with a particle size of 20-40 mm and a thickness of H2 = 52 cm, steel sl...

Embodiment 2

[0029] as attached figure 1 , attached figure 2 and attached image 3 As shown, the treated tail water volume is 21m 3 The overall specification of the multi-stage filler subsurface flow constructed wetland in / d is L×B×H=17.96m×5.24m×2.00m, which is divided into 5 areas, and a set of length L1=1.0m is constructed sequentially along the tailwater flow direction Pool I, water distribution tank II with length L2 = 1.0m, wetland bed area III with length L3 = 12m, sedimentation area IV with length L4 = 1.0m, and clear water pool V with length L5 = 1.0m. It is made of notoginseng wall bricks, and the water distribution tank and the sedimentation area are separated by two or four brick water distribution walls (small holes with a diameter of 20mm at a distance of 300mm are laid on the wall). The wetland bed area is sequentially filled with gravel with a particle size of 40-50 mm and a thickness of H1 = 26 cm, red brick fragments with a particle size of 20-40 mm and a thickness o...

Embodiment 3

[0031] as attached figure 1 , attached figure 2 and attached image 3 As shown, the treated tail water volume is 56m 3 The overall specification of the multi-stage filler subsurface flow constructed wetland in / d is L×B×H=26.96m×4.74m×2.00m, which is divided into 5 areas, and a set of length L1=1.0m is built sequentially along the tailwater flow direction Pool I, water distribution tank II with length L2 = 1.0m, wetland bed area III with length L3 = 21m, sedimentation area IV with length L4 = 1.0m, and clear water pool V with length L5 = 1.0m. It is made of notoginseng wall bricks, and the water distribution tank and the sedimentation area are separated by two or four brick water distribution walls (small holes with a diameter of 20mm at a distance of 300mm are laid on the wall). The wetland bed area is sequentially filled with gravel with a particle size of 40-50 mm and a thickness of H1 = 26 cm, red brick fragments with a particle size of 20-40 mm and a thickness of H2 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com