Cleaning device

A cleaning device and a technology to be cleaned are applied in the field of copper ball cleaning devices for electroplating and cleaning devices, which can solve the problems of poor cleaning effect, high manual labor intensity, and low cleaning efficiency, and achieve easy maintenance, good support effect, and machine durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

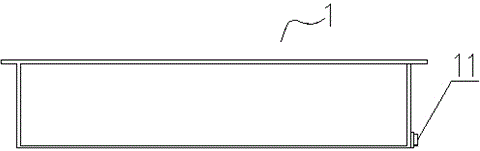

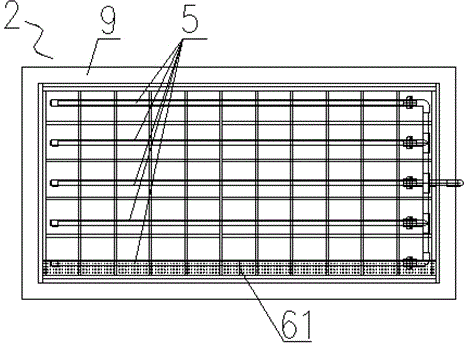

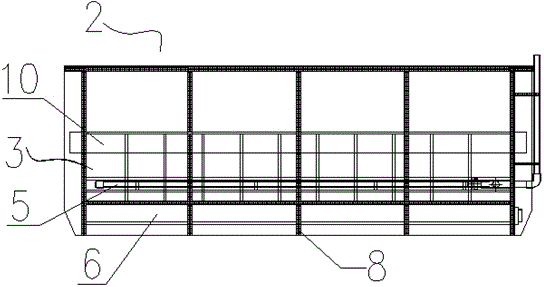

[0059] This embodiment provides a cleaning device, taking the cleaning of copper balls for electroplating as an example, and referring to the attached Figure 1-6 Shown in detail.

[0060] Such as Figure 1-4 As shown, the above-mentioned cleaning device includes a cleaning container 2, and also includes a dividing device that carries the parts to be cleaned and divides the inner cavity of the cleaning container 2 into an upper space 21 and a lower space 22, and a drum is arranged in the lower space 22. The wind device 4 is provided on the partition device to introduce the air bubbles generated by the blower device 4 from the lower space 22 into the upper space 21 to push the cleaning liquid to flush when cleaning the piece to be cleaned. The communication part of the article to be cleaned.

[0061] The above-mentioned technical solution is the core technical solution of the present invention. When the above-mentioned cleaning device is used to clean the copper balls for ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com