Rolling bearing integrated with permanent support suitable for jack-up construction

A technology of permanent support and jacking method, which is applied in the erection/assembly of bridges, bridges, buildings, etc. It can solve the problems of large influence of flexible piers, adverse effects of bridge piers, complex device structure, etc., and achieve low cost and simplified construction operation process , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

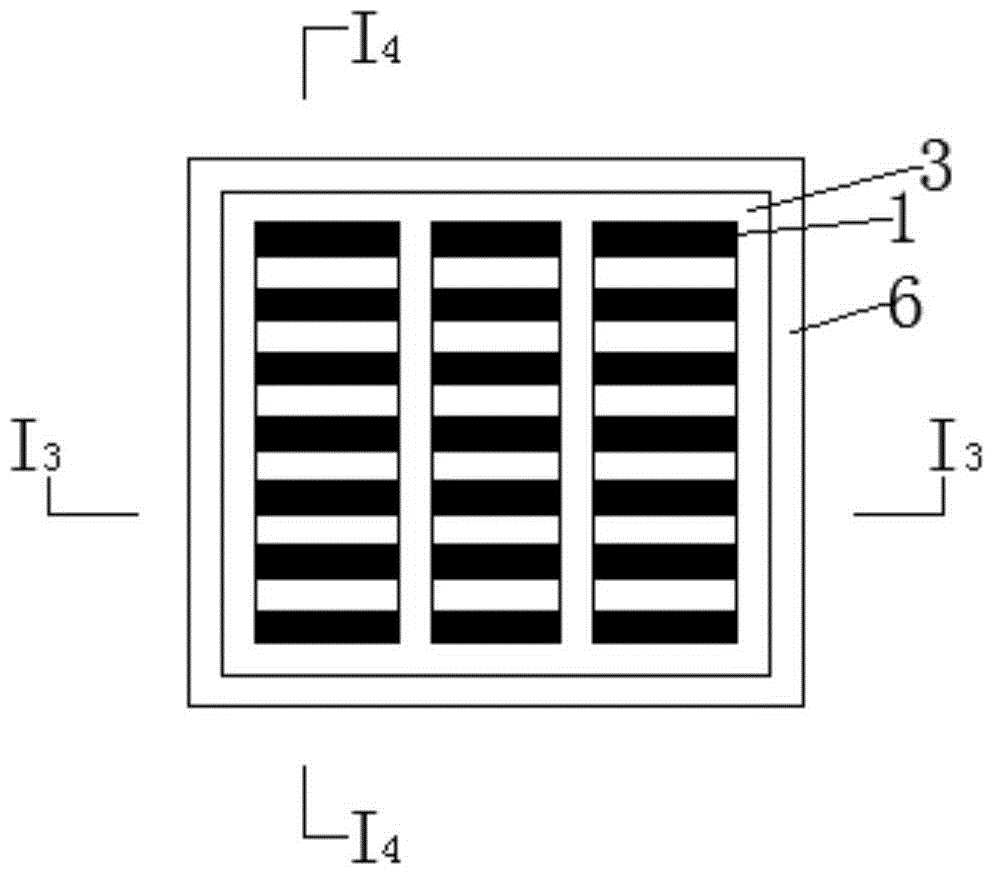

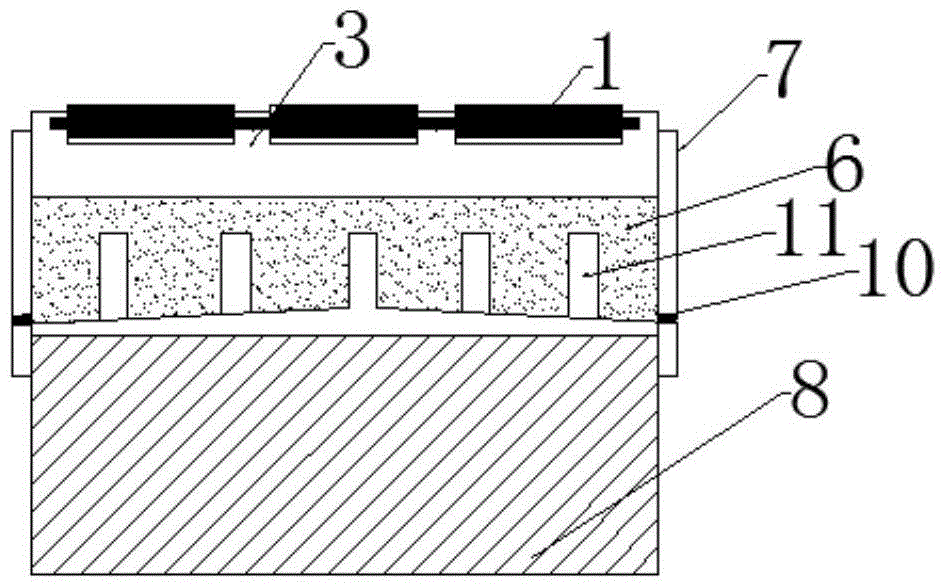

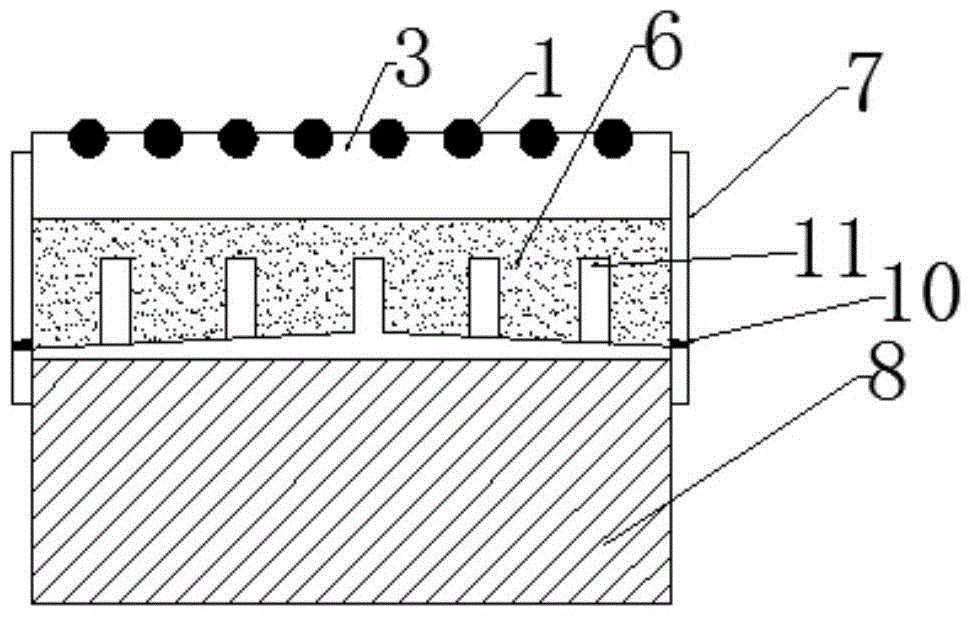

[0012] The rolling bearing integrated with the permanent support suitable for the jacking method construction provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 — image 3 As shown, the rolling bearing integrated with the permanent support suitable for the jacking method construction provided by the present invention includes a plurality of cast steel rollers 1, standard sand 6, a slide plate 3, a casing 7, a common support 8, and a plurality of screws 10 and a plurality of steel columns 11; wherein the shell 7 is a box structure with an opening formed on the upper end, and the lower end is fixed on the upper end of the common support 8, and at least one screw hole is formed at the lower part of each side, and is blocked by a screw 10 The screw hole is equipped with standard sand 6 inside; the lower ends of multiple steel columns 11 are fixed on the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com