Road surface sweeping and snow removal vehicle and manufacturing method

A cleaning and snowmobile technology, applied in road cleaning, snow surface cleaning, cleaning methods, etc., can solve the problems of low utilization rate of equipment, single equipment performance, increase equipment purchase volume, etc., and achieve high utilization rate and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

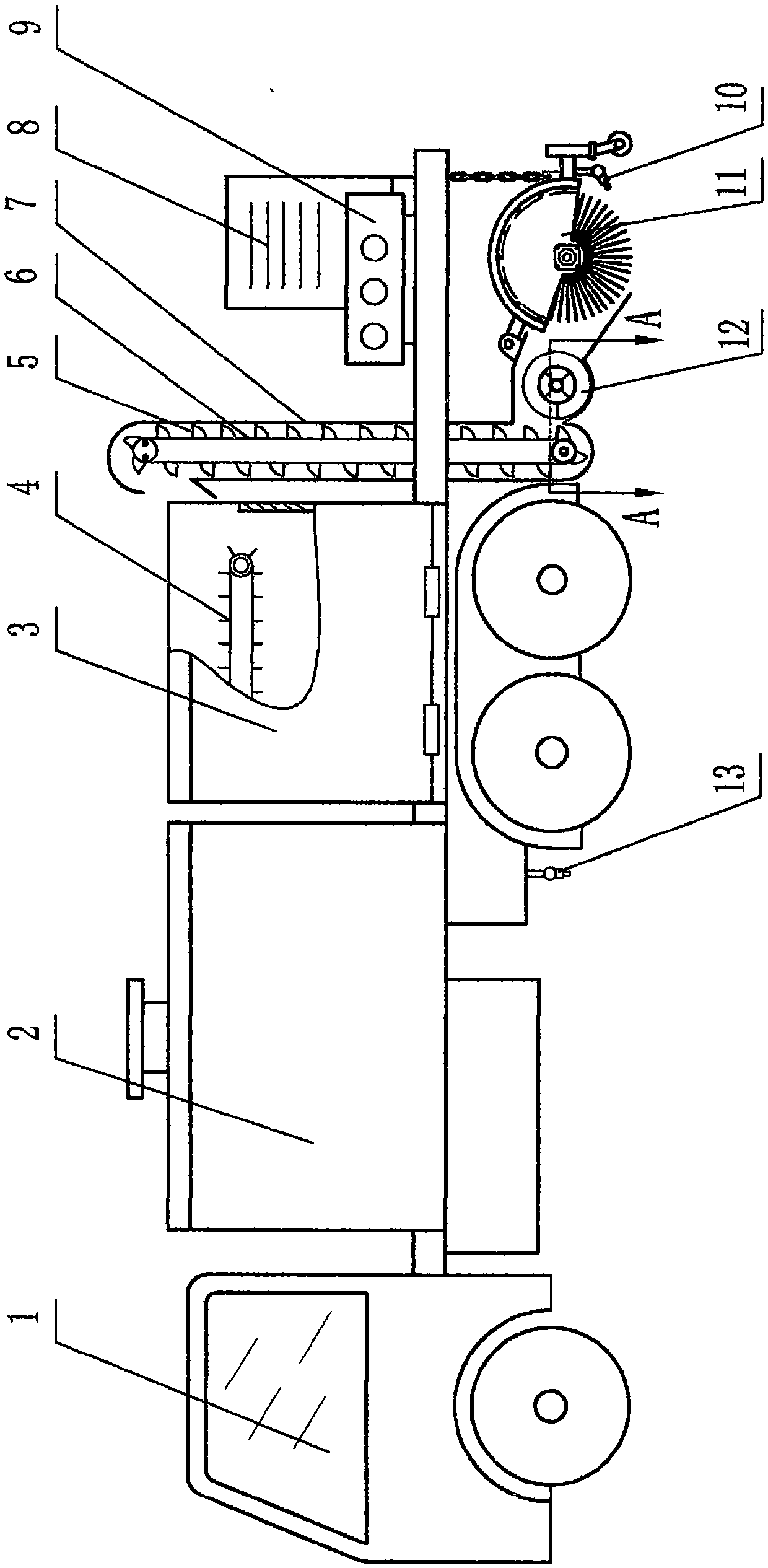

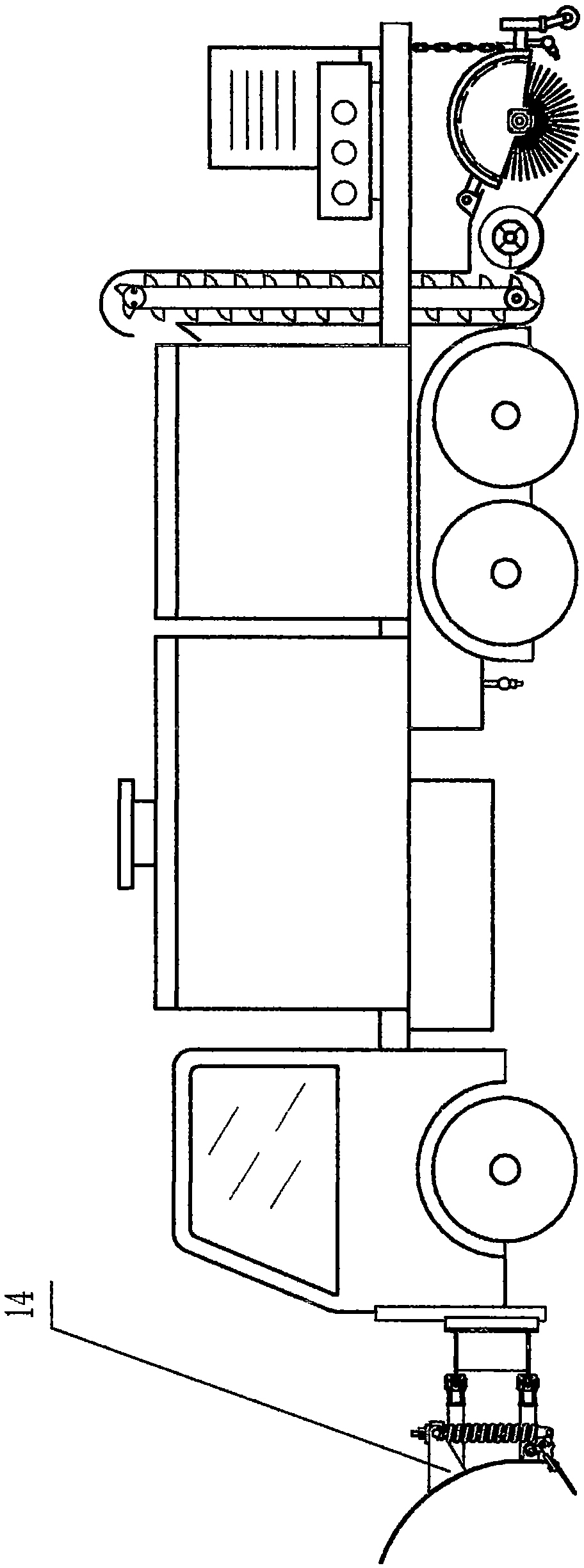

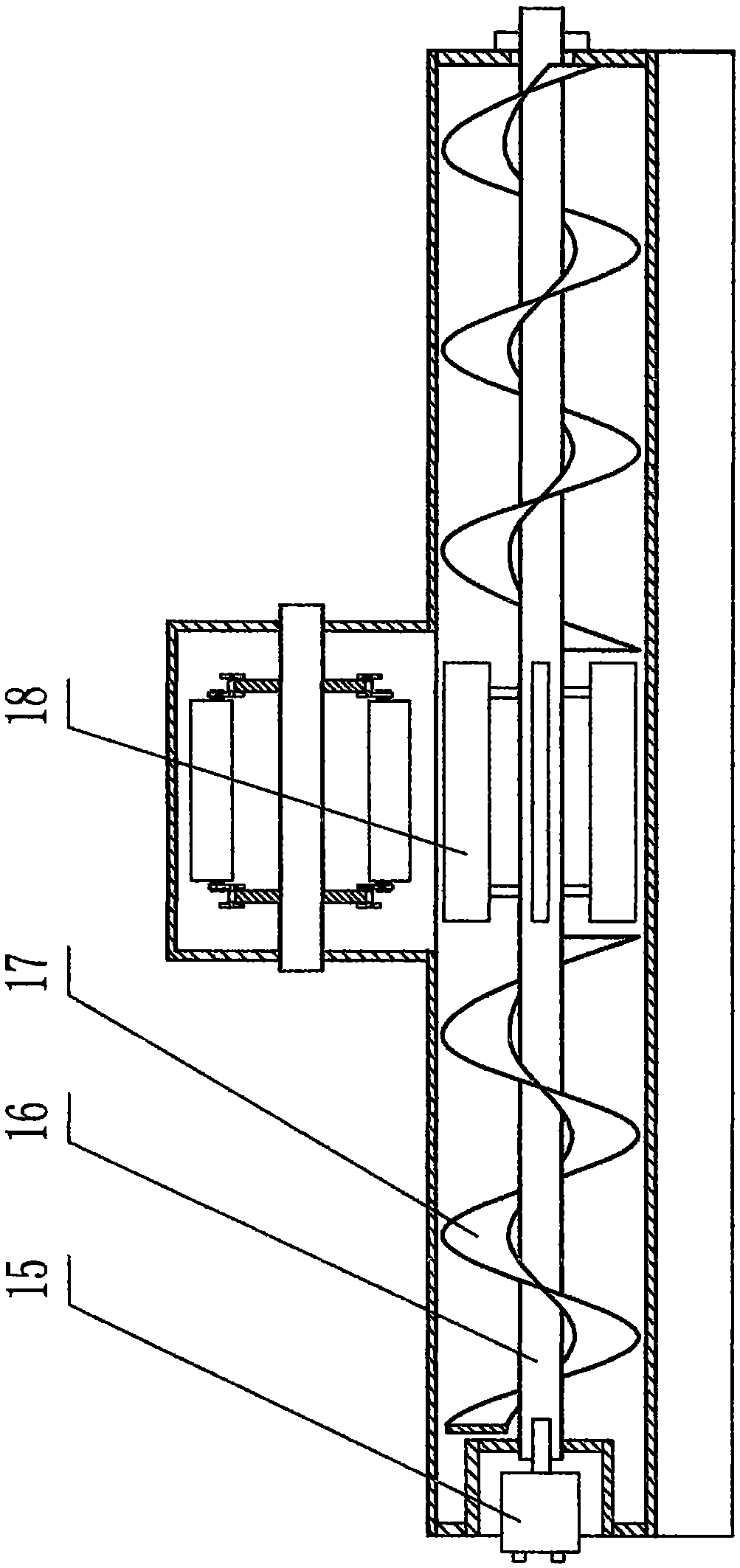

[0018] figure 1 The special-purpose vehicle chassis (1) is the second-class chassis of the engineering vehicle that meets the relevant national standards, and is connected to the hydraulic oil pump from the transmission power take-off interface to provide power for the related structural operations. The clean water tank (2) and the garbage can (3) are assembled On the special-purpose vehicle chassis (1), the special-purpose vehicle chassis (1) includes an assembled engine (8), a high-pressure water pump (9), and the engine (8) drives the high-pressure water pump (9) to work, a hoist (7), a conveyor ( 12) Both are installed on the back of the special vehicle chassis (1), the cleaning roller brush (11) is installed on the back of the conveyor (12) and connected with the special vehicle chassis (1), and the height can be adjusted up and down, and the high-pressure water nozzle (10) is assembled Below the cleaning roller brush (11), the spray nozzle (13) is installed in front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com