Installation device and installation method for spring vibration isolator

A technology of spring isolator and installation device, which is applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc. Simple structure, simple construction, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

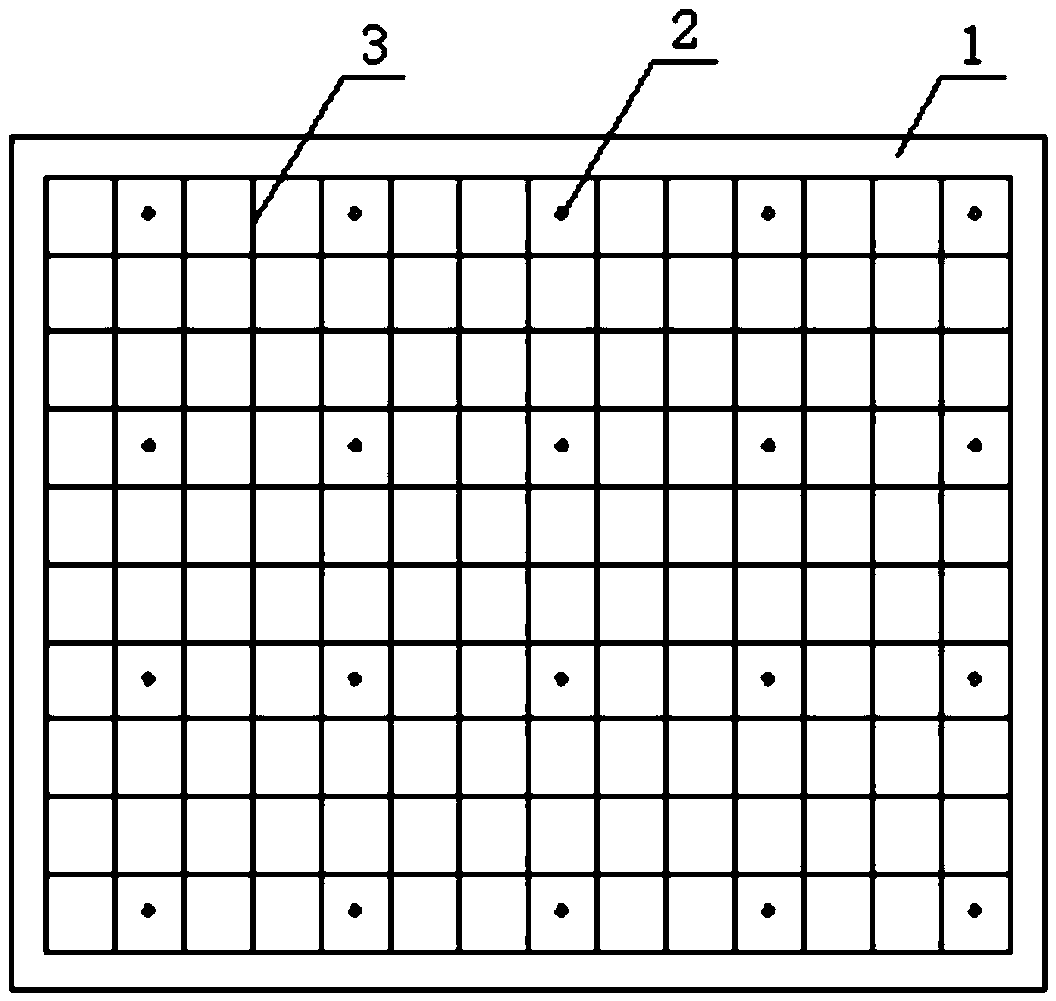

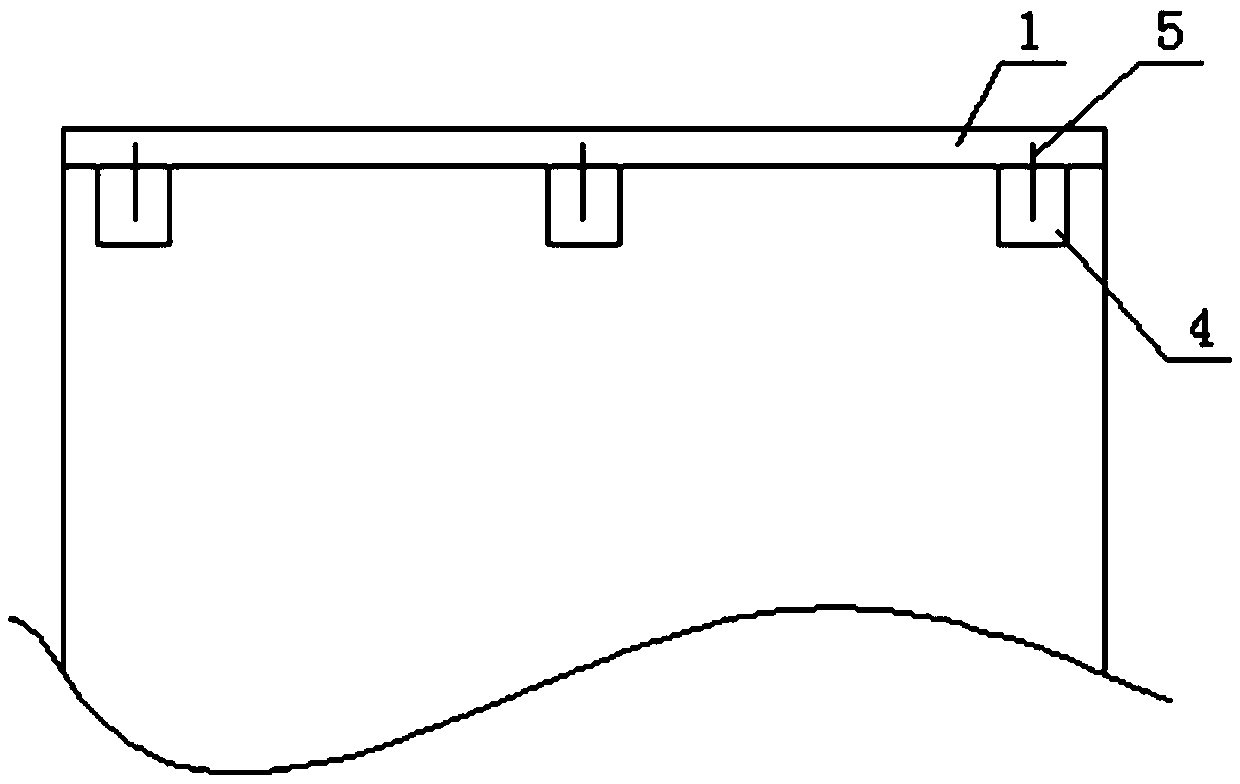

[0029] A spring vibration isolator installation device, comprising: angle steel square frame 1, new and old concrete bonding layer reinforced steel bar 2, anti-cracking reinforced steel bar 3, steel plate embedded parts 4, short steel bars 5; the angle steel square is welded by ∠50*5 angle steel Frame 1, the anti-crack reinforcement mesh 3 is installed in the angle steel frame 1, the new and old concrete bonding layer reinforcement bars 2 are interspersed in the crack prevention reinforcement mesh 3, and the new and old concrete bonding layer reinforcement bars 2 and the crack prevention reinforcement mesh 3 are located The plane is vertical, the steel plate embedded part 4 is located under the angle steel frame 1, and the short steel bar 5 is welded on the steel plate embedded part 4.

[0030] Before pouring the first layer of the spring isolator foundation, three 10cm*10cm steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com