Segmented type deflecting screw drill for horizontal drilling

A technology for horizontal drilling and screw drilling tools, applied in drilling equipment, earth-moving drilling, impact drilling, etc., can solve problems such as damage to the drill bit motor assembly, complicated processing and manufacturing of elastic casings, and reduced drilling efficiency, and achieve smooth sliding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

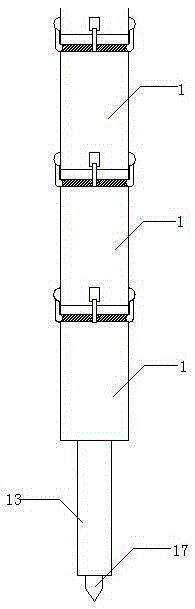

[0037] Such as figure 1 Shown is the horizontal section of the present invention picture , the present invention is a Segmented deflecting screw drilling tool for horizontal drilling , consisting of whipstock and drilling sections,

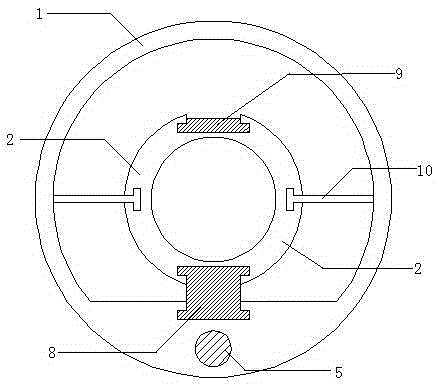

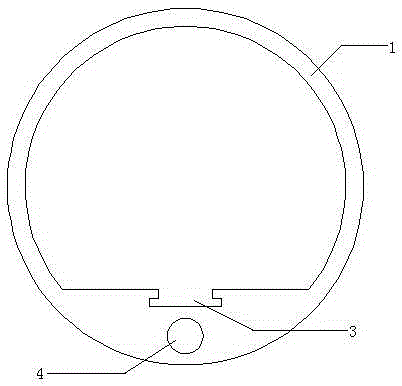

[0038] Such as figure 2 Horizontal section for kickoff picture ,include Such as image 3 The whipping outer cylinder 1 shown and Such as Figure 4 Kickoff pup 2 shown. The skew-making outer cylinder 1 is a hollow cylinder, one side of which is provided with a curved sliding groove 3 along the axial direction, and the skew-making outer cylinder 1 is provided with a columnar curved hole 4 near the edge of the curved sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com