Method for heating viscoelastic components of an actuator and clutch actuator

An actuator, viscoelastic technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

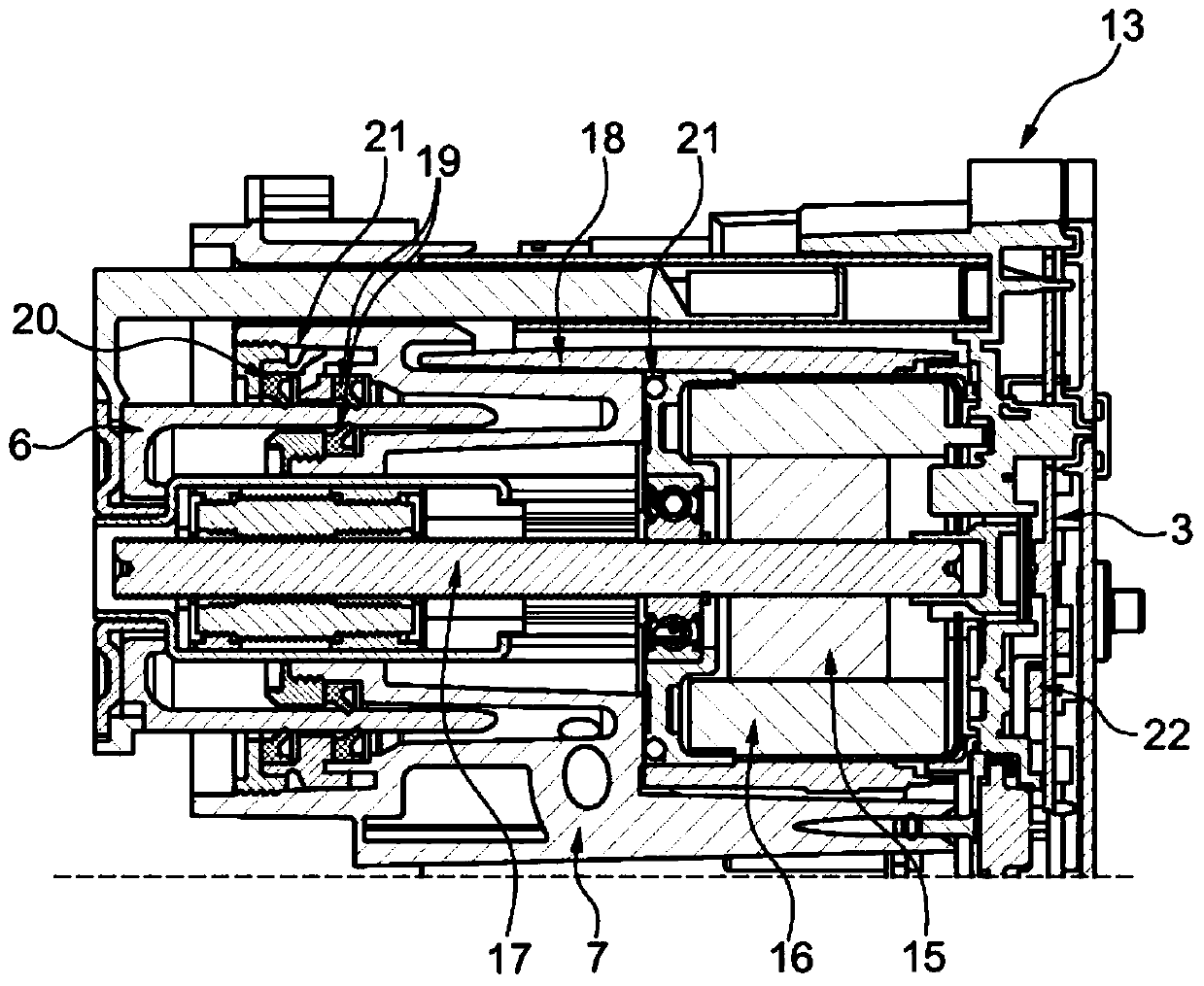

[0017] The same features are provided with the same reference signs.

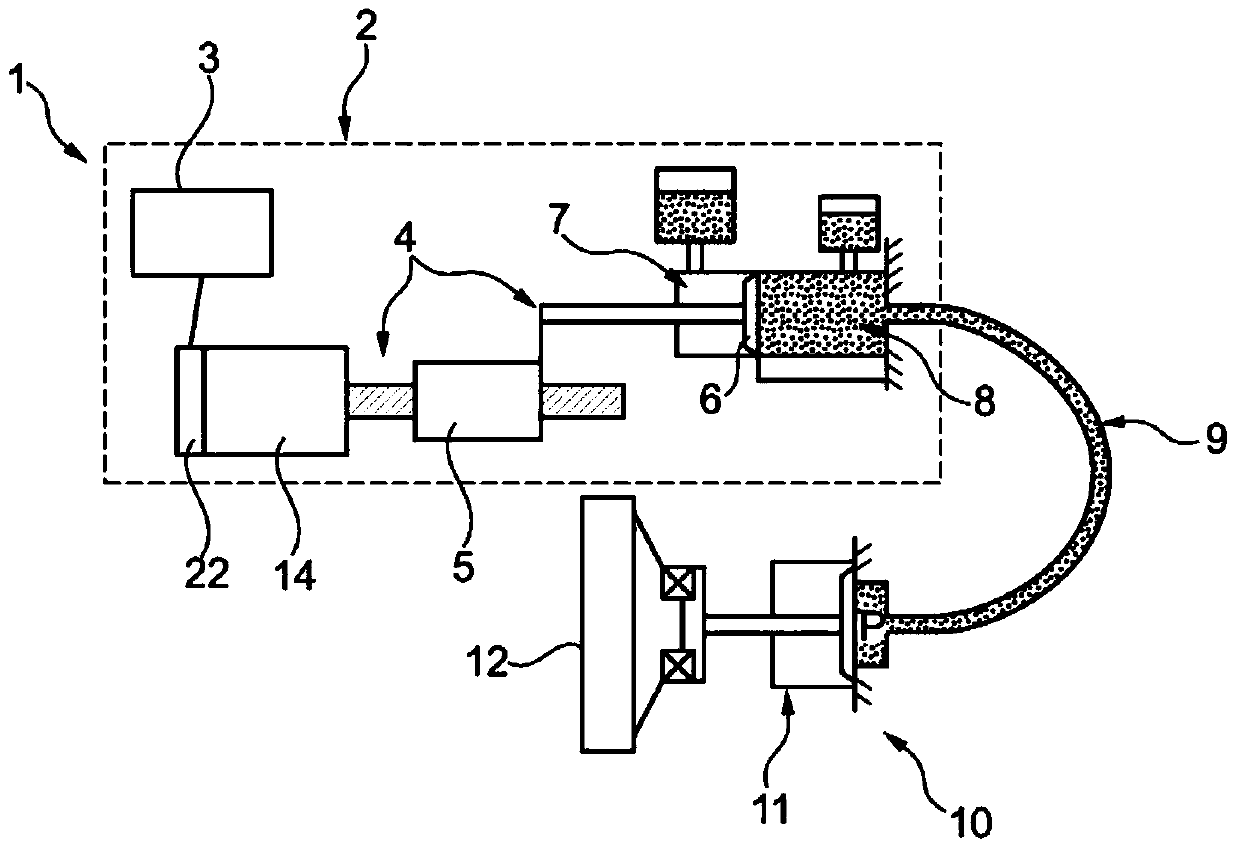

[0018] figure 1 The principle structure of a hydrostatic clutch system 1 for a motor vehicle is shown. The schematic diagram only shows the structure of one of the two clutches used to operate the dual clutch transmission, and the operation of the other clutch is similarly performed. The hydrostatic clutch system 1 includes a control device 3 on the active side 2, which controls an actuator 4. The actuator 4 is connected to the piston 6 of the master cylinder 7 via the transmission device 5. When the actuator 4 and then the piston 6 in the active cylinder 7 shift to the right along the actuator path, the volume of the active cylinder 7 changes, thereby building a pressure p in the active cylinder 7, which pressure passes through the hydraulic fluid 8 The pipeline 9 is transmitted to the driven side 10 of the hydrostatic clutch system 1. The length and shape of the hydraulic line 9 are adapted to the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com