Electrically controlled pneumatic shunt valve

A diverter valve, electronic control technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of coil burning, leakage, truck vibration, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

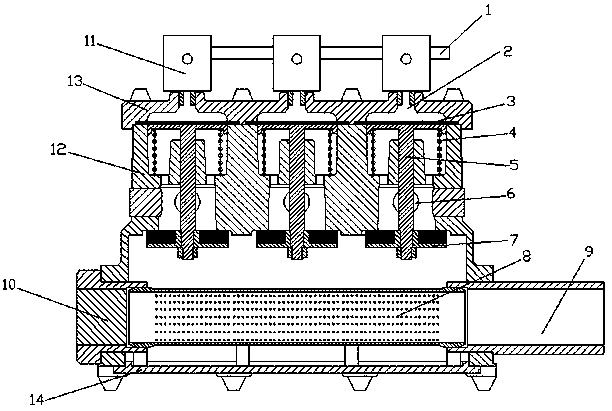

[0018] Please refer to figure 1 , in this specific embodiment, three two-position three-way solenoid valves (11) are connected in series through the intake pipe (1) and installed on the air port (2) of the housing (13); the valve body (12) is fixed on the housing (13 ) inner cavity; the piston body (5) is supported and suspended on the valve body (12) by the tension spring (4), the upper end is sealed with the housing (13) by a rubber diaphragm (3) to form an air chamber, and the lower end is passed by a blocking plate (7 ) The compressed rubber diaphragm (3) seals with the valve body (12) to form a small cavity; the valve body (12) is provided with a water outlet (6) at the position of the small cavity, and the bottom of the valve body (12) passes through the bottom plate (14) The main cavity is sealed and formed; the filter screen (8) traverses the main cavity of the valve body (12), one end is connected to the valve body (12) through a hand-tightened screw plug (10), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com