Electroplating drying machine

A dryer and rack technology, applied in the direction of dryers, drying, progressive dryers, etc., can solve problems such as complex operation, achieve good cooling effect, reduce manual operation, and extend the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

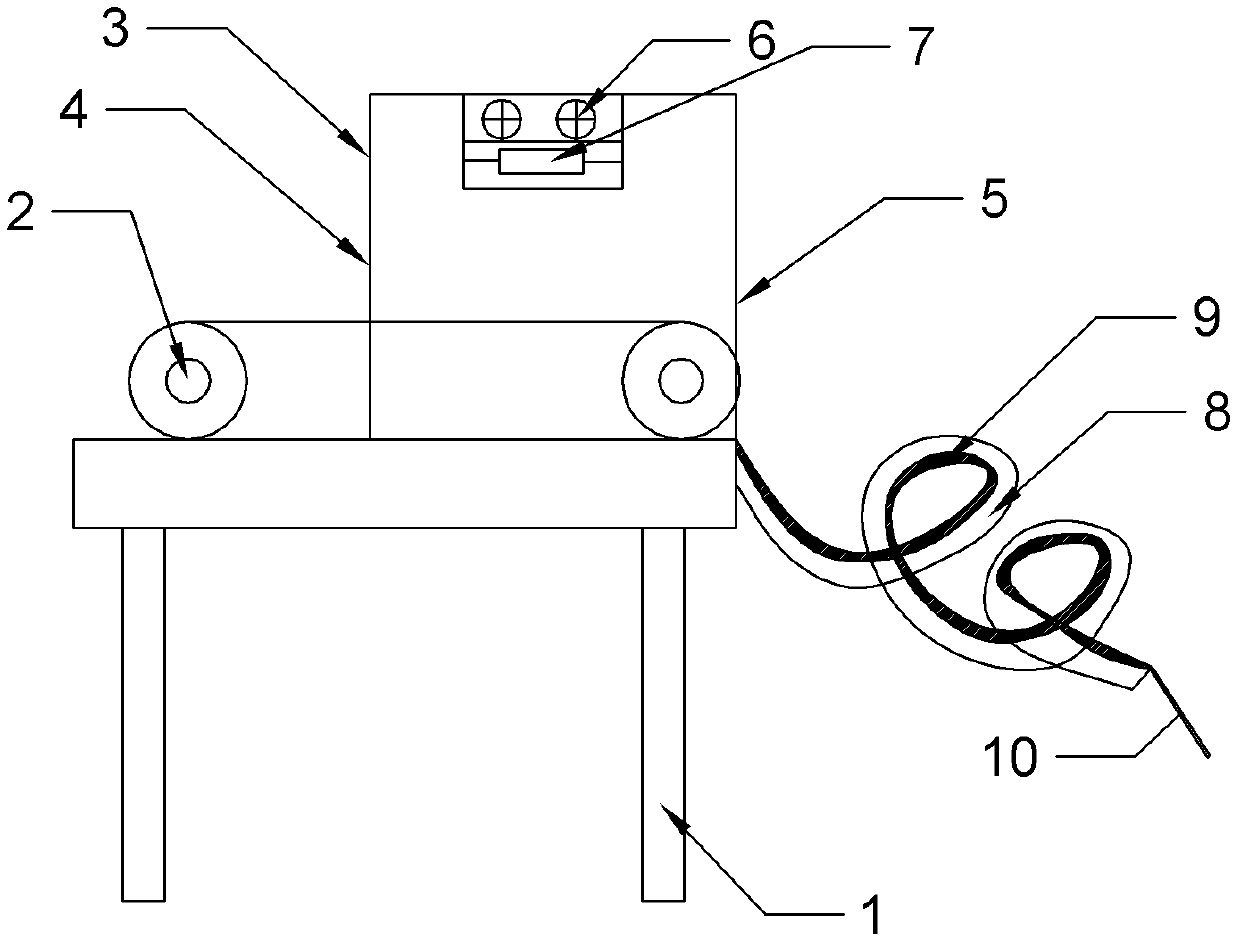

[0015] Example 1, such as figure 1 As shown, the electroplating dryer includes a frame 1 and a transmission mechanism 2, the transmission mechanism 2 is fixed on the frame 1, and the transmission mechanism 2 is a chain drive, which facilitates the contact of air with auto parts and increases the drying effect. A sealing cover 3 is arranged above the conveying mechanism 2 , and an inlet 4 and an outlet 5 are respectively arranged on both sides of the sealing cover 3 , and the conveying mechanism 2 passes through the sealing cover 3 and is flush with the outlet 5 . A fan 6 and an electric heating tube 7 are sequentially arranged in the sealing cover 3 from top to bottom, and the electric heating tube 7 is located directly above the transmission mechanism 2 to facilitate drying of auto parts by hot air. The outlet end of the conveying mechanism 2 is provided with a spiral pipe 8, and the pipe 8 is inclined downward, and the angle between the pipe 8 and the horizontal plane is 30°...

Embodiment 2

[0016] Embodiment 2 is different from Embodiment 1 in that the angle between the pipeline 8 and the horizontal plane is 40°, and the temperature of the cold water layer 9 is 10°.

Embodiment 3

[0017] Embodiment 3 differs from Embodiment 1 in that the angle between the pipeline 8 and the horizontal plane is 50°, and the temperature of the cold water layer 9 is 20°.

[0018] Firstly, the cleaned auto parts are placed on the transmission mechanism 2, and the auto parts are brought into the sealing cover 3 along with the transmission of the transmission mechanism 2, and the electric heating tube 7 generates heat after being energized, and the fan 6 transfers the heat of the electric heating tube 7 along the Blow in a downward direction to the surface of auto parts, which is convenient for drying auto parts. After drying, the auto parts enter the pipe 8 along with the transmission mechanism 2. Under the gravity of the auto parts, the auto parts move downward along the spiral pipe 8. The cold water layer 9 in the pipe 8 can absorb the heat on the auto parts. Let it cool down and cool down. The cooled car parts thus go directly into the tray for collection.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap