Main bearing reduced scale performance test bench of large wind turbine

A technology for wind turbines and main bearings, applied in the direction of mechanical bearing testing, etc., can solve the problems of high test cost, inability to meet the bearing measurement, poor generality of the test device, etc., and achieve the effect of reducing the test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

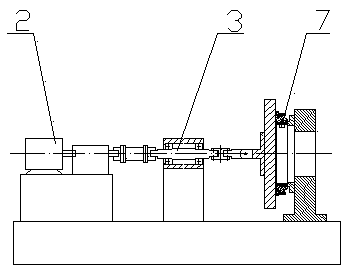

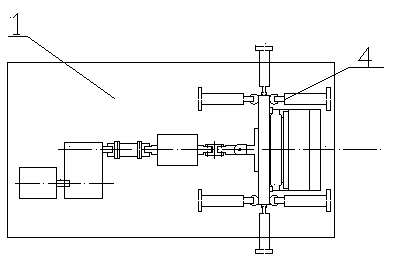

[0020] Such as Figure 1 to Figure 8As shown, the scaled-scale performance test bench of the main bearing of a large wind turbine includes a fixed platform 1, a driving device 2, a rotor device 3, a loading device 4, a hydraulic system 5, a control device 6 and a test system 7, a driving device 2, and a rotor device 3 and the loading device 4 are sequentially connected and fixed on the fixed platform 1. The test system 7 is installed between the outer ring transition plate 22 and the inner ring transition plate 23 of the loading device 4. The fixed platform 1 includes a large platform 8, a fixed motor platform 9, a rotor The device installation platform 13 and the small platform 15, the fixed motor platform 9 and the rotor device installation platform 13 are respectively installed on the large platform 8, the drive device 2 includes a drive motor 10, a reducer 11 and a diaphragm coupling 12, and the drive motor 10 and the speed reducer The reducer 11 is connected with the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com