Sampler and method for measuring multi-phase-flow phase holdup distribution

A sampler and multiphase flow technology, applied in sampling devices and other directions, can solve the problems of unpredictable flow direction of sampling points, complicated flow of multiphase reactors, affecting the accuracy of sampling results, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

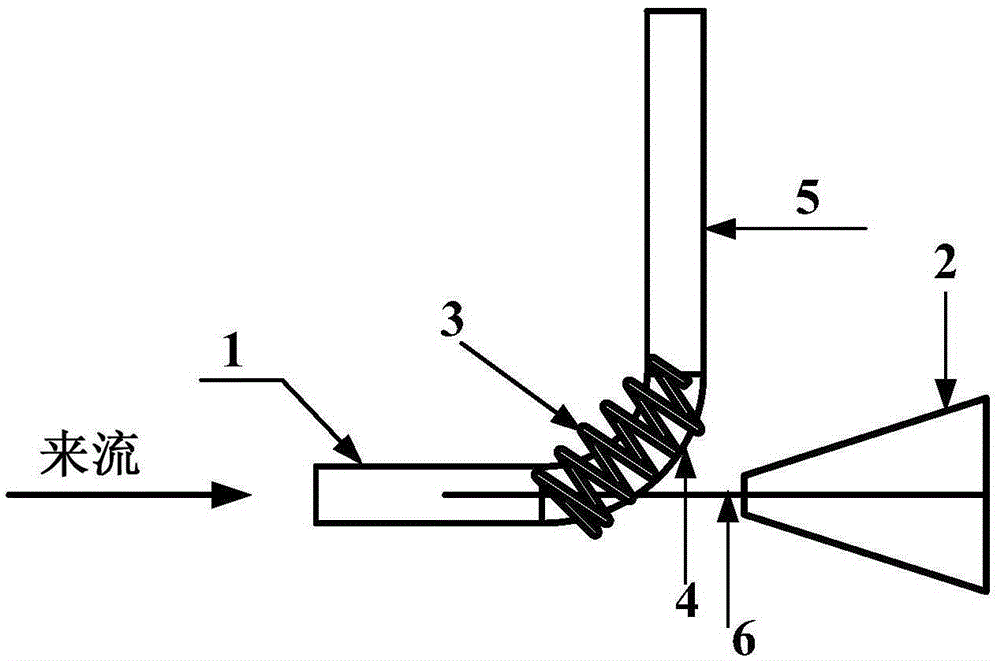

[0048] A sampler for measuring holdup distributions of multiphase fluid phases, such as figure 1 shown. The sampler comprises a front-end sampling tube 1, a freely turning connecting tube, a rear-end sampling tube 5 and a regulator for adjusting the direction of the front-end sampling tube 1 nozzle, and the front-end sampling tube 1 is connected to the rear-end sampling tube through the connecting tube. tube 5 is connected, the regulator includes an adjustment rod 6 and an adjustment piece 2 installed on one end of the adjustment rod 6, the other end of the adjustment rod 6 is connected with the front sampling tube 1, and the number of the adjustment pieces 2 is four , the spacing between the regulating pieces 2 is the same, the shape of the regulating pieces 2 is trapezoidal, and the sides of the trapezoid facing the incoming flow are two parallel sides.

[0049] The front end sampling tube 1 of the sampler is a plexiglass tube material, its inner diameter is 6mm, the wall t...

Embodiment 2

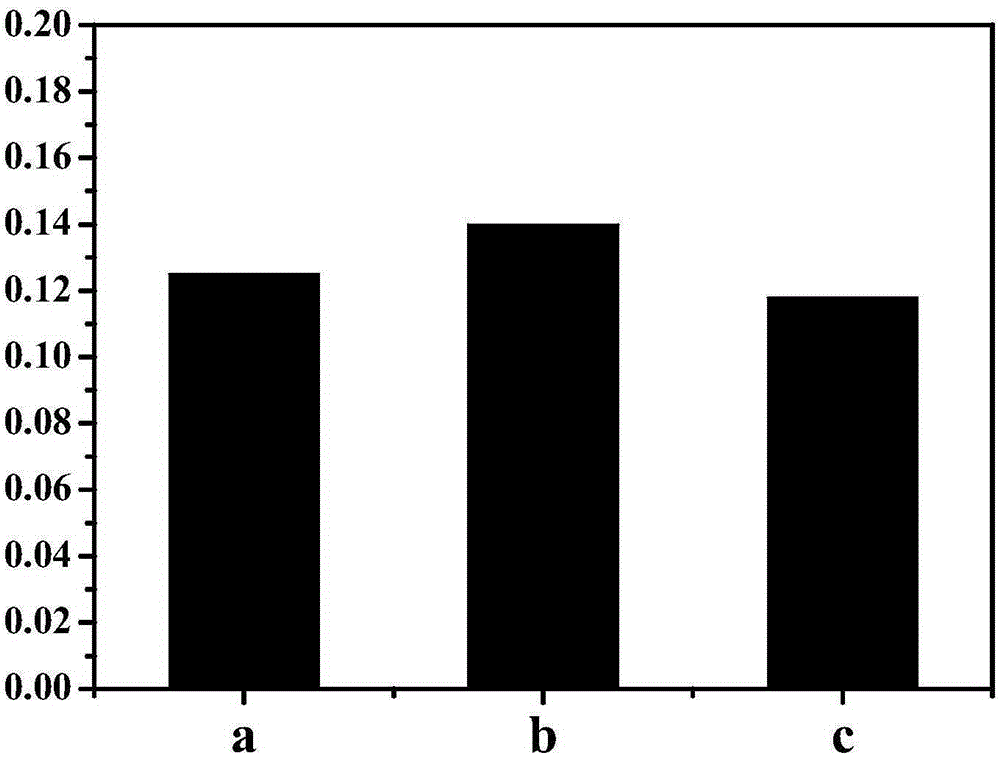

[0052] The sampler described in Example 1 was used to measure the local solid phase holdup in the liquid-solid stirred tank reactor.

[0053] Experiment is carried out in the plexiglass stirring tank of diameter T=380mm, and experiment system is quartz sand (200 orders) and deionized water, and average solid content rate is 5wt% (mass ratio); Static liquid level height H=T, liquid The phase temperature is 22°C; the impeller is a 45° push-down six-fold open turbine impeller, the diameter of the impeller is D=T / 3, the height of the impeller from the bottom is C=T / 3, the bottom of the elliptical tank, the ratio of the major axis to the minor axis It is 2:1; Taking the lowest point of the center of the elliptical bottom of the stirred tank as the coordinate origin, the sampler described in Example 1 was adopted to measure the solid holdup at the position of (r / R, z / H)=(0.8,0.34) , wherein, r / R and z / H respectively represent the center of the bottom of the stirred tank as the origi...

Embodiment 3

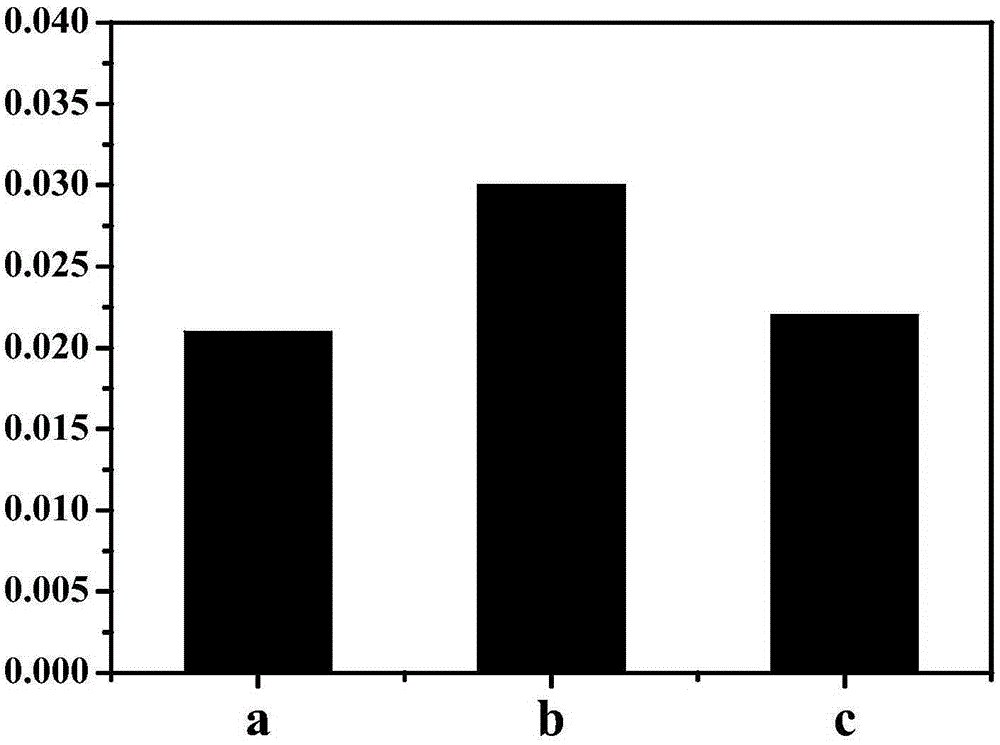

[0055] The sampler described in Example 1 was used to measure the local gas phase holdup in the gas-liquid stirred tank reactor.

[0056] The experiment was carried out in a flat-bottomed plexiglass stirring tank with a diameter of T=380mm. The experimental system was air and deionized water; the height of the static liquid level was H=T, and the liquidus temperature was 22°C; the stirring paddle was a standard Rushton paddle, and the diameter of the paddle was D= T / 3, paddle height C=T / 3 from the bottom; Taking the lowest point of the center of the elliptical bottom of the stirred tank as the coordinate origin, the sampler described in Embodiment 1 was used to measure (r / R, z / H) in the gas-liquid stirred tank )=(0.8, 0.34) position gas holdup, and compared with the measurement results of the traditional sampler with the conductivity probe and the sampling nozzle placed horizontally, the results are as follows image 3 As shown, the samplers of the present invention all obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com