Cloth inspecting machine based on visual robot

A technology of robots and cloth inspection machines, applied in the field of cloth inspection machines, can solve the problems of increasing infrastructure investment, inability to store, manually filling in data, etc., and achieve the effect of large market promotion prospects, reducing the number of laborers, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

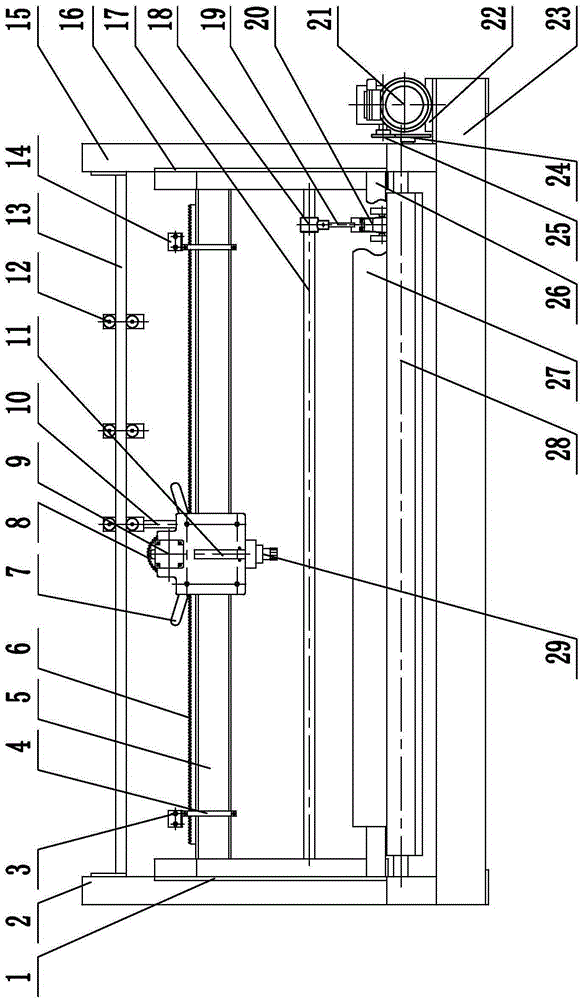

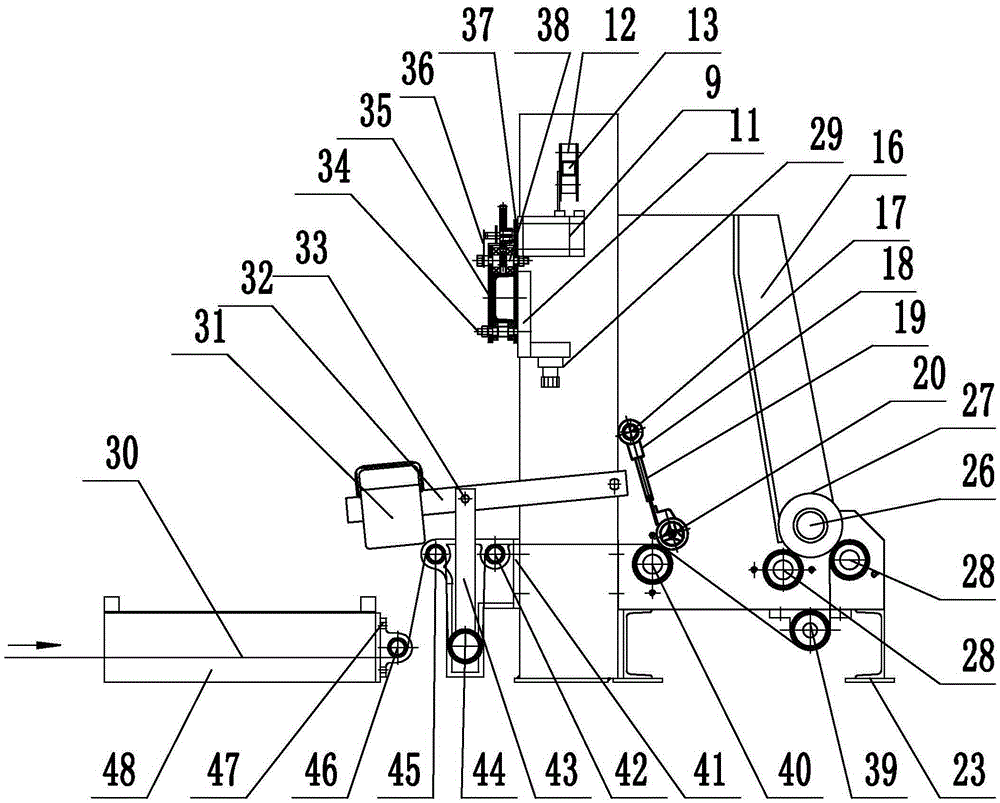

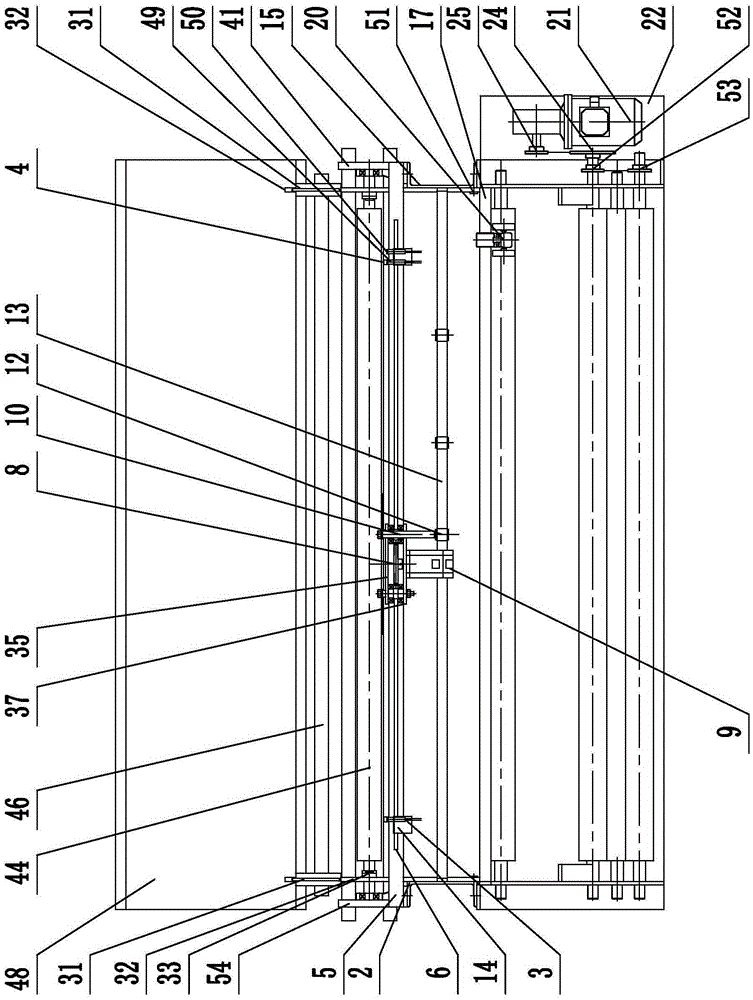

[0030] Such as Figure 1-3 As shown, the cloth inspection machine based on the visual robot of the present invention includes a tension control device, a visual robot image acquisition device, a meter counting device and a cloth rolling device, and the tension control device, the visual robot image acquisition device, the meter counting device and the cloth rolling device are mutually to cooperate in work.

[0031] Tension control device among the present invention comprises the support that is made up of left support 54 and right support 41, tension rod two 42 are connected on the right support 41, tension control device also comprises pedal 48, tension rod one 45 and tension rod two 42, pedal 48 is provided with cloth guide bar seat 47, cloth guide bar 46 is installed on the cloth guide bar seat 47, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com