Antifriction device of power cable installation in pipe

A power cable and pipe threading technology, which is applied in the field of pipe laying auxiliary devices, can solve problems affecting the safety and reliability of power cable operation, damage to the cable body, cable puller, and large friction between the power cable and the pipe wall, etc., to achieve improved Safe and reliable operation, solution to excessive traction, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

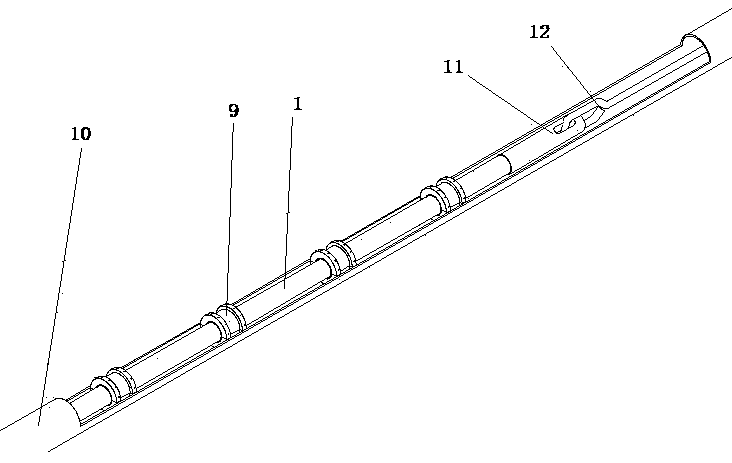

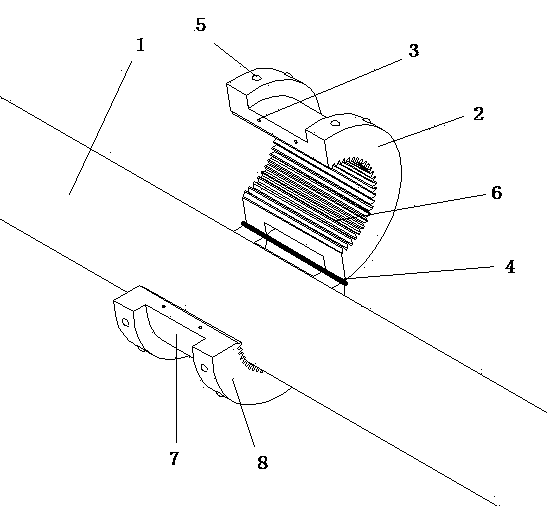

[0021] Such as figure 1 As shown, in order to change the original way that the cable 1 directly contacts the pipeline surface and reduce the frictional resistance of the pipeline when the cable 1 is laid and pulled, the device includes a cable sleeve 9 that can pass through and hold the cable, and is evenly embedded in the cable sleeve. 9. The rolling ball 5 on the side of the outer cylinder. The cable bushing 9 is provided with a rolling ball accommodation chamber, and the rolling ball accommodation chamber and the rolling ball 5 are in clearance fit so that the rolling ball 5 can roll in the rolling ball accommodation chamber. The cable bushing 9 includes an upper bushing 2 and a lower bushing 8, the upper bushing 2 and the lower bushing 8 are connected through the rotating shaft 4, and the upper bushing 2 and the lower bushing 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com