Installation method of anti-jamming optical fiber perimeter guard detector

An installation method and optical fiber perimeter technology, applied in the direction of alarms by breaking/disturbing the straightened rope/metal wire, mechanical activation of anti-theft alarms, etc., can solve the problem of increasing the false alarm rate of the detector and affecting the detection of the detector. , security accuracy and poor accuracy, etc., to increase the anti-interference factor, increase the sensing area, and overcome the effects of their own errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

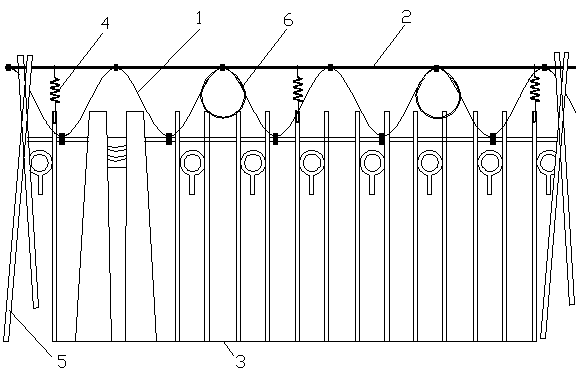

[0040] A method for installing an anti-interference optical fiber perimeter protection detector, comprising the following steps:

[0041] a. According to the form of the surrounding wall of the factory area, select the spring for laying the fixed linear vibration detector 1, and install it along the surrounding wall of the factory area;

[0042] b. The linear vibration detector 1 is laid sinusoidally through the spring support. According to the requirements of the linear vibration detector 1 on the strength and flexibility of the straight spring steel wire above the spring, the steel wire is selected as galvanized round steel 2;

[0043] c. In combination with the requirements of the size of the defense zone, determine the length of the linear vibration detector 1 within the unit length;

[0044] d. Test whether the position of the defense zone is consistent with the actual position according to the defense zone segment, and adjust the sensitivity of the linear vibration detec...

Embodiment 2

[0047] A method for installing an anti-interference optical fiber perimeter protection detector, comprising the following steps:

[0048] a. According to the form of the surrounding wall of the factory area, select the spring for laying the fixed linear vibration detector 1, and install it along the surrounding wall of the factory area;

[0049] b. The linear vibration detector 1 is laid sinusoidally through the spring support. According to the requirements of the linear vibration detector 1 on the strength and flexibility of the straight spring steel wire above the spring, the steel wire is selected as galvanized round steel 2;

[0050] c. In combination with the requirements of the size of the defense zone, determine the length of the linear vibration detector 1 within the unit length;

[0051] d. Test whether the position of the defense zone is consistent with the actual position according to the defense zone segment, and adjust the sensitivity of the linear vibration detec...

Embodiment 3

[0057] A method for installing an anti-interference optical fiber perimeter protection detector, comprising the following steps:

[0058] a. According to the form of the surrounding wall of the factory area, select the spring for laying the fixed linear vibration detector 1, and install it along the surrounding wall of the factory area;

[0059] b. The linear vibration detector 1 is laid sinusoidally through the spring support. According to the requirements of the linear vibration detector 1 on the strength and flexibility of the straight spring steel wire above the spring, the steel wire is selected as galvanized round steel 2;

[0060] c. In combination with the requirements of the size of the defense zone, determine the length of the linear vibration detector 1 within the unit length;

[0061] d. Test whether the position of the defense zone is consistent with the actual position according to the defense zone segment, and adjust the sensitivity of the linear vibration detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com