Arrangement for capturing image of printing substrate web

A technology for printing materials and formats, applied in the field of image devices, can solve problems such as the inability to achieve uniform illumination in the image area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

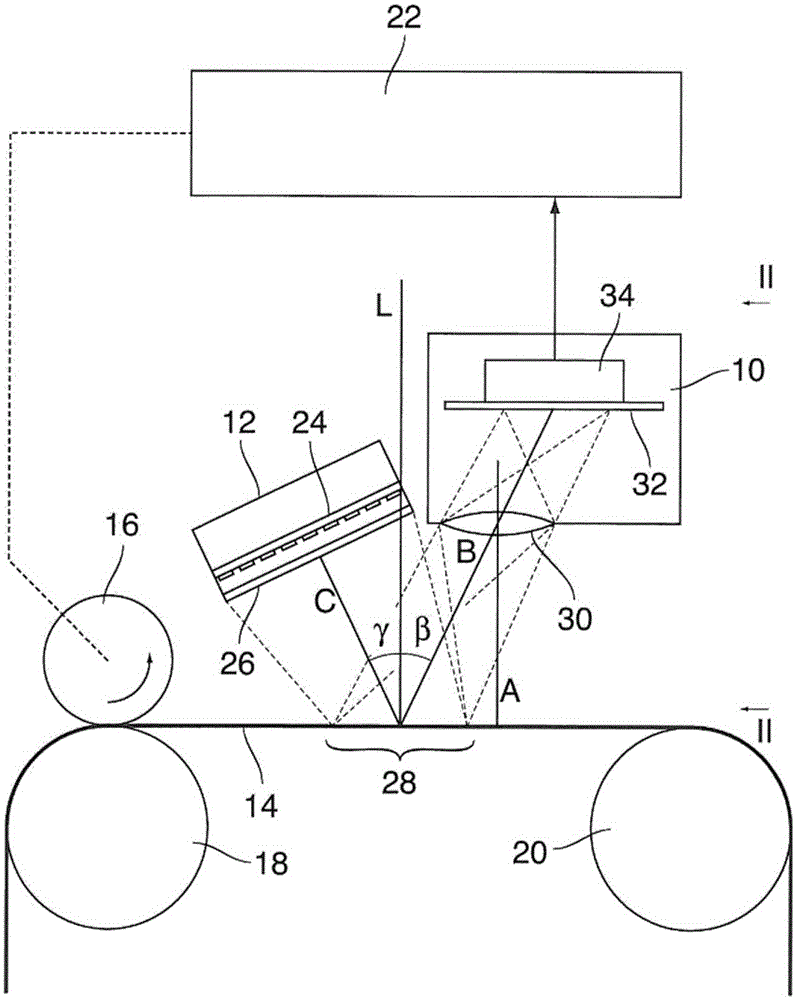

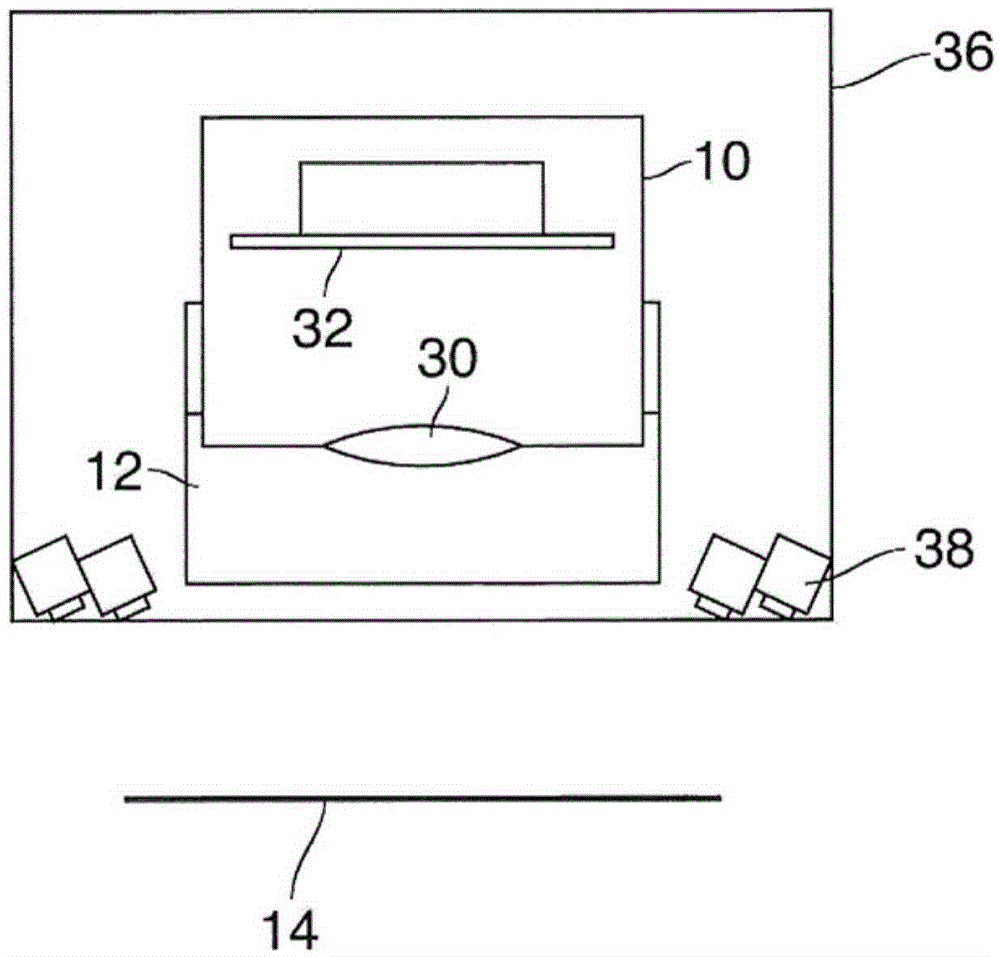

[0013] exist figure 1 The image recording device shown in FIG. 2 includes a camera 10 and a light source 12 , which are arranged in the printing press in such a way that images printed on a printing material web 14 can be recorded and electronically processed. In this respect, only the printing cylinder 16 , the pressure cylinder 18 and the guide cylinder 20 , through which the printing material web 14 is drawn off from the pressure cylinder, are shown in the printing press. The registration control device 22 processes the image captured by the camera 10 and controls the drive and lateral position of the printing cylinder 16 in such a way that the color component images printed by the printing cylinder 16 are compared with other, not shown, images. The other color component images printed by the printing equipment on the printing material web are accurately overlapped.

[0014] The light source 12 comprises a circuit board 24 equipped with light-emitting diodes, in front of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com