Processing system having a polar structure for planar substrates

A technology for processing equipment and plane substrates, which is applied in the field of processing equipment for polar structures of plane substrates, can solve problems such as large base surface requirements, high cost and the like, and achieve the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

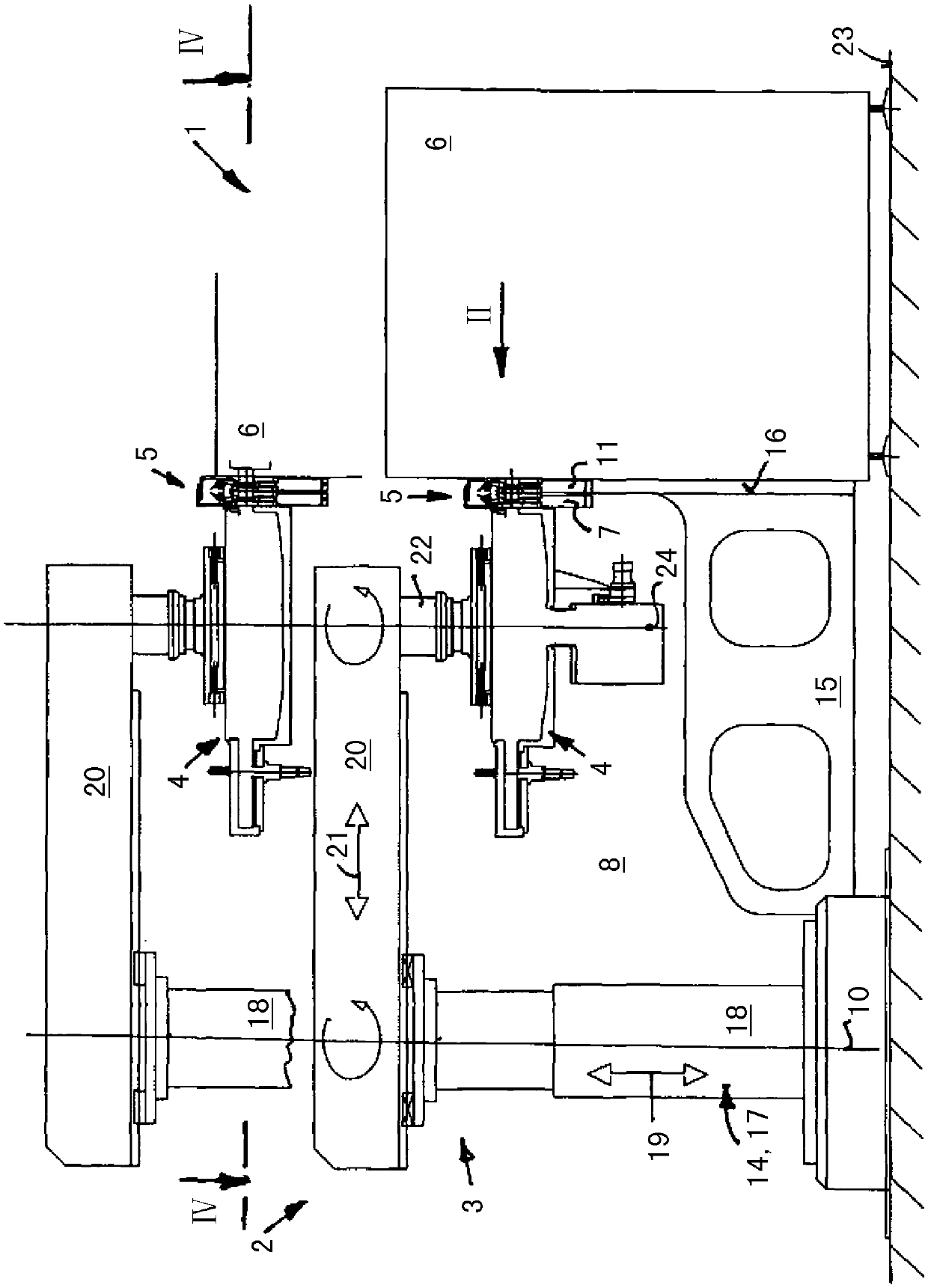

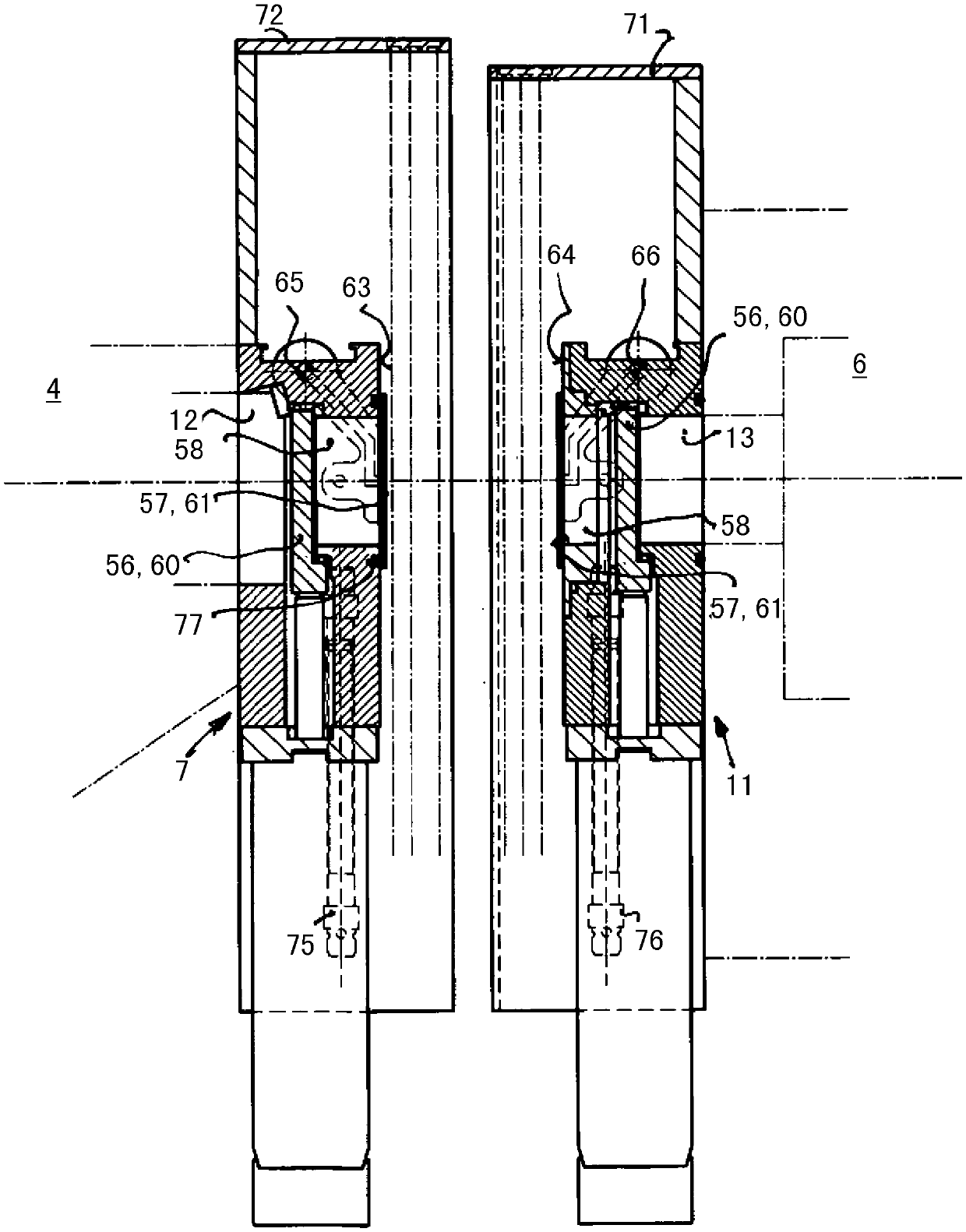

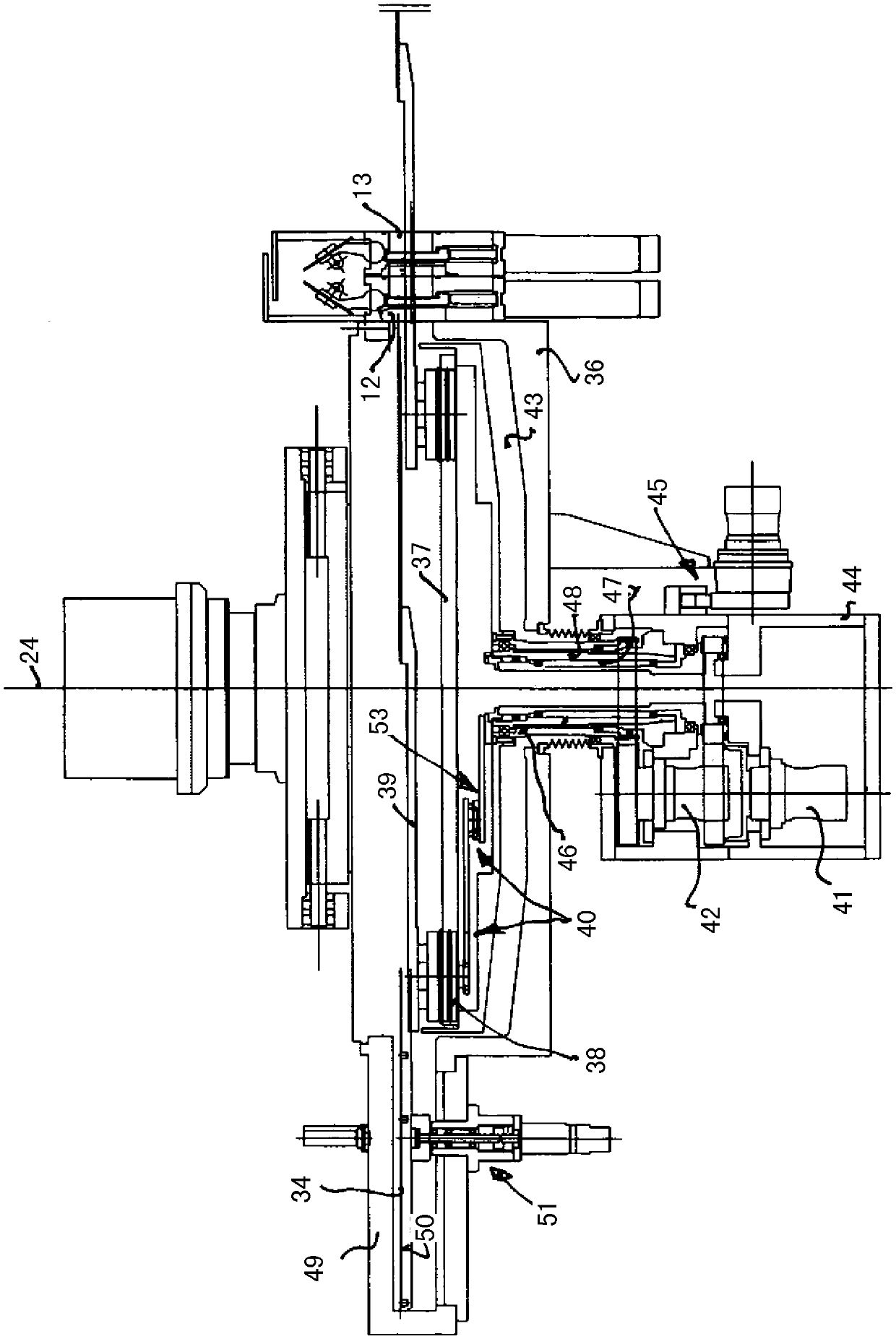

[0032] figure 1 For processing equipment with polar structures in accordance with Figure 4 The simplified sectional view of the section line I-I in shows a handling device 2 with a support device 3 and a vacuum transfer chamber 4 supported by the support device. A vacuum transfer chamber is a transfer chamber in which special conditions of the gas atmosphere can be maintained, also during the transfer (reference ambient conditions), up to the highest and highest cleanliness classes.

[0033] This transfer chamber is docked to the individual process stations 6 via a coupling device 5 , wherein the handling device 2 is coupled to the valve via a support device 3 , a vacuum transfer chamber 4 and (cf. the drawing) a coupling device 5 which is fixed in position relative to the vacuum transfer chamber 7 forms the central base module 8 of the processing plant 1 . For this base module 8 on a circle 9 around its central axis of rotation 10 (eg Figure 4 shown) is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com