An intelligent vacuum suction device

A vacuum suction cup, intelligent technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of high cost and long cycle, and achieve the effect of strong applicability, energy saving and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

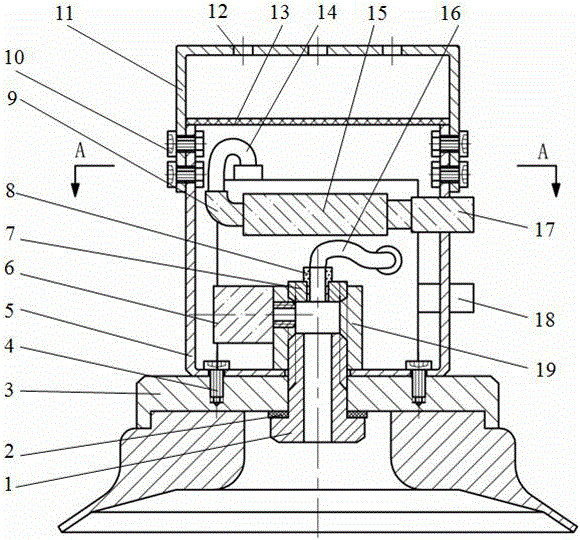

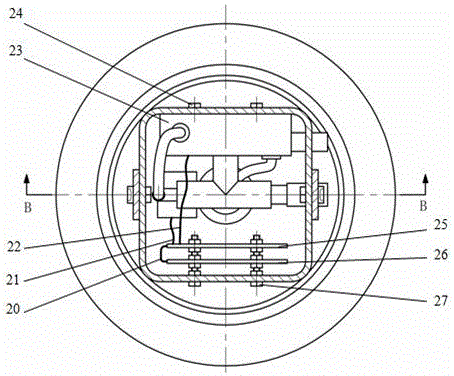

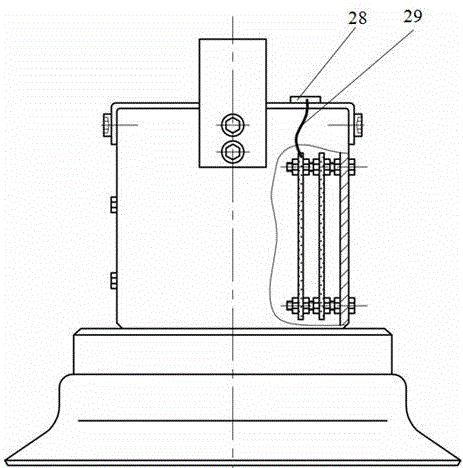

[0021] see figure 1 , an intelligent vacuum chuck device in the present invention includes a vacuum chuck and a control unit, the control unit includes a control box body and three groups of six-position four-way integrated valves, a vacuum generator, and a control circuit module accommodated and fixed in the control box body and a communication module, the control box body includes a metal box body and a non-metal box cover, and the metal box body is fixed on a vacuum suction cup. Three groups of six-position four-way integrated valves include compressed air inlet, air outlet, negative pressure air inlet 31, suction cup interface, and three two-position two-way electromagnetic reversing valves D3, D1 and D2 through the air pipe such as Figure 4 The pneumatic circuit is connected in series in sequence. The compressed air inlet is connected to the air pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com