Solar module rear side encapsulation element and solar module

A solar module and backside encapsulation technology, applied in the field of solar modules, can solve problems such as low mechanical stability, inability to protect solar modules for a long time, and limited UV radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

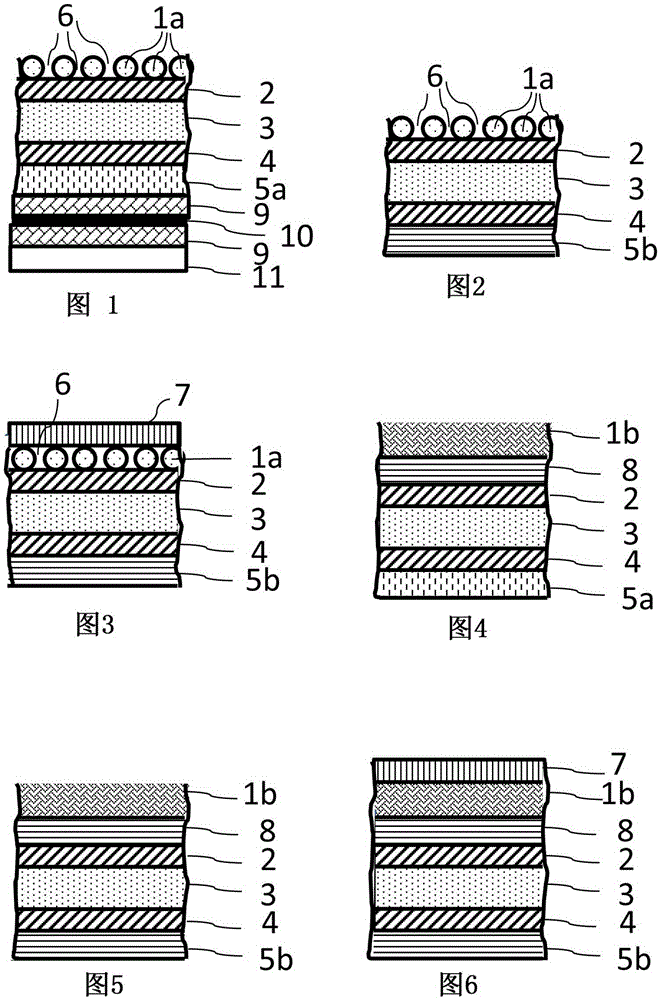

[0037] figure 1 A schematic and not to scale partial cross-sectional view of a solar module with a solar module backside encapsulation member according to a first embodiment is shown. The solar module has a front encapsulation member 11 and an encapsulation material 9 arranged on the back of the member, and the front of the front encapsulation member is the light incident surface of the solar module. In addition, the solar module includes solar cell strings 10 arranged on the back side of the front packaging member 11, the solar cell strings 10 are connected to each other and embedded in the packaging material 9, so that the solar cell strings 10 face the front packaging Both the side of the component 11 and the side of the solar cell string 10 facing away from the front-side encapsulation component 11 are surrounded by the encapsulation material 9 . In addition, the solar module has a solar module backside encapsulation component, which is arranged on the side of the solar c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com