Printed battery production line

A technology for printing batteries and production lines, applied in the field of printing production lines, can solve the problems of large space occupation, increased cost, unfavorable production workshop layout, etc., and achieves the effects of low cost, avoiding high cost and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

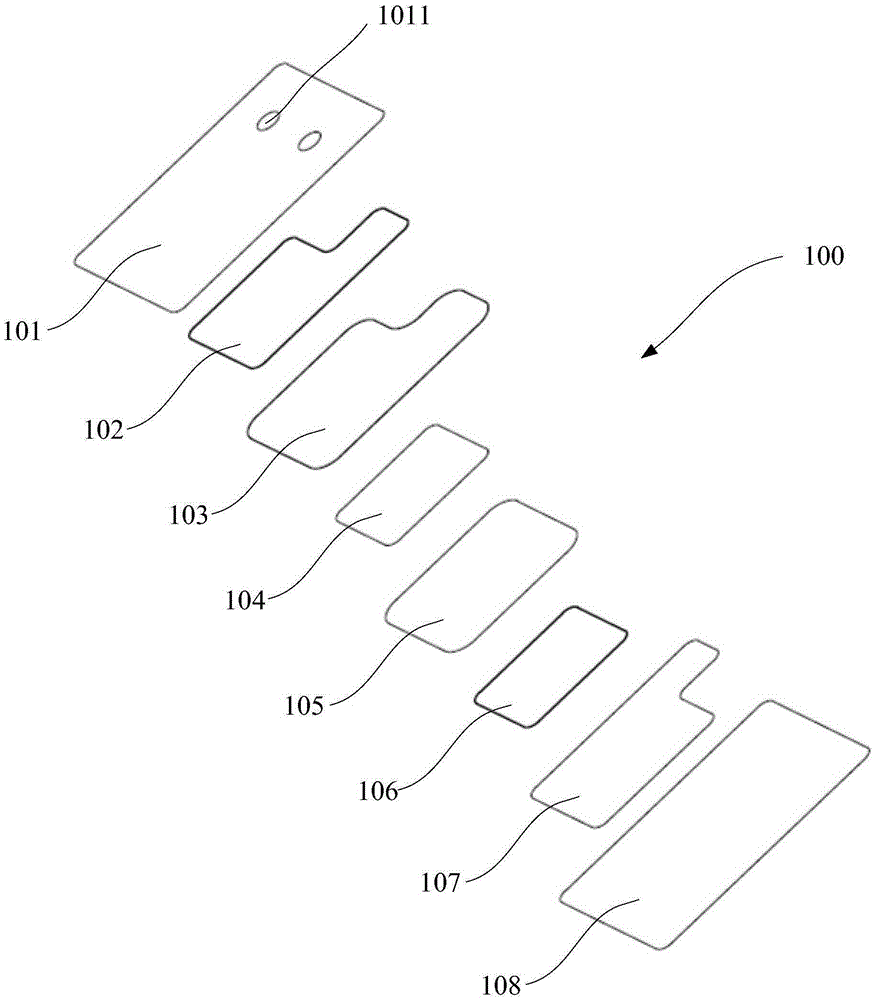

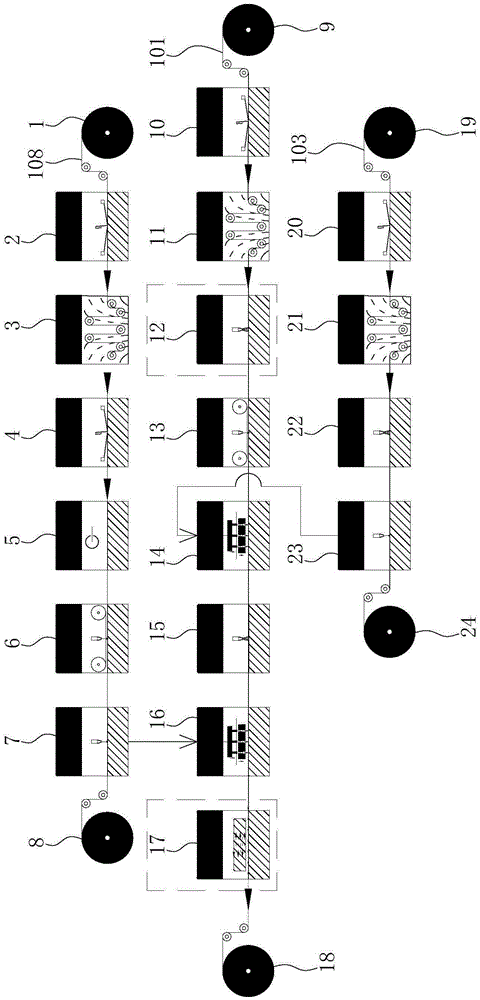

[0028] Attached below Figures 1 to 5 The technical solutions of the present invention are further described through specific implementation methods.

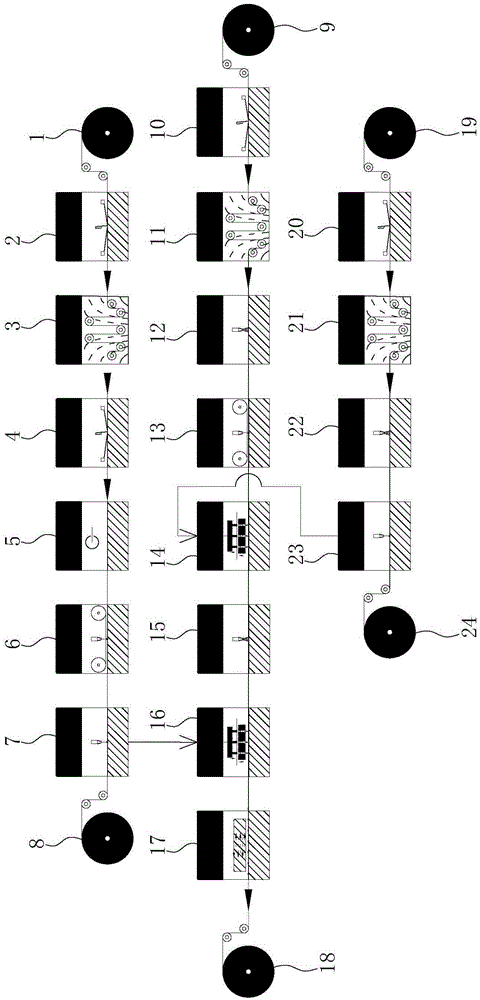

[0029] Such as figure 1 As shown, a printed battery production line includes a main production line, a first auxiliary production line and a second auxiliary production line located on both sides of the main production line, and the intermediate products produced in the first auxiliary production line and the second auxiliary production line are combined with the main production line , to produce paper batteries or smart labels;

[0030] The main production line includes self-adhesive printing equipment 10, second drying equipment 11, first electrolyte adding equipment 12, third laser die-cutting equipment 13, first laminating equipment 14, second electrolyte Adding device 15, second bonding device 16, battery and antenna connection device 17;

[0031] The first auxiliary production line includes collector printing equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com