Rotary machining device and machining method therefor

A technology of rotary processing and rotary device, applied in metal processing equipment, gear cutting machines, mechanical equipment, etc., can solve the problems of time-consuming, inability to improve the productivity of helical gears, and the lack of research on dressing devices, so as to reduce frequency and improve productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Hereinafter, embodiments of a rotary processing machine and a processing method thereof will be described with reference to the drawings.

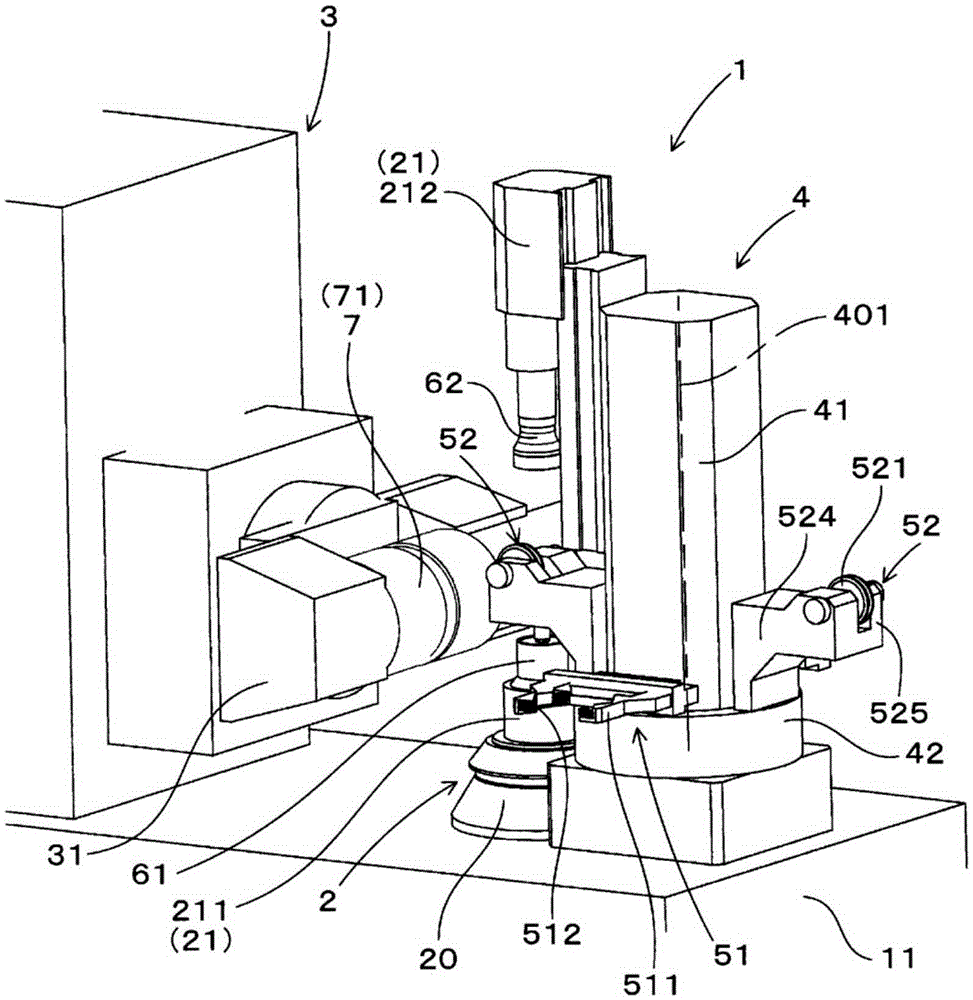

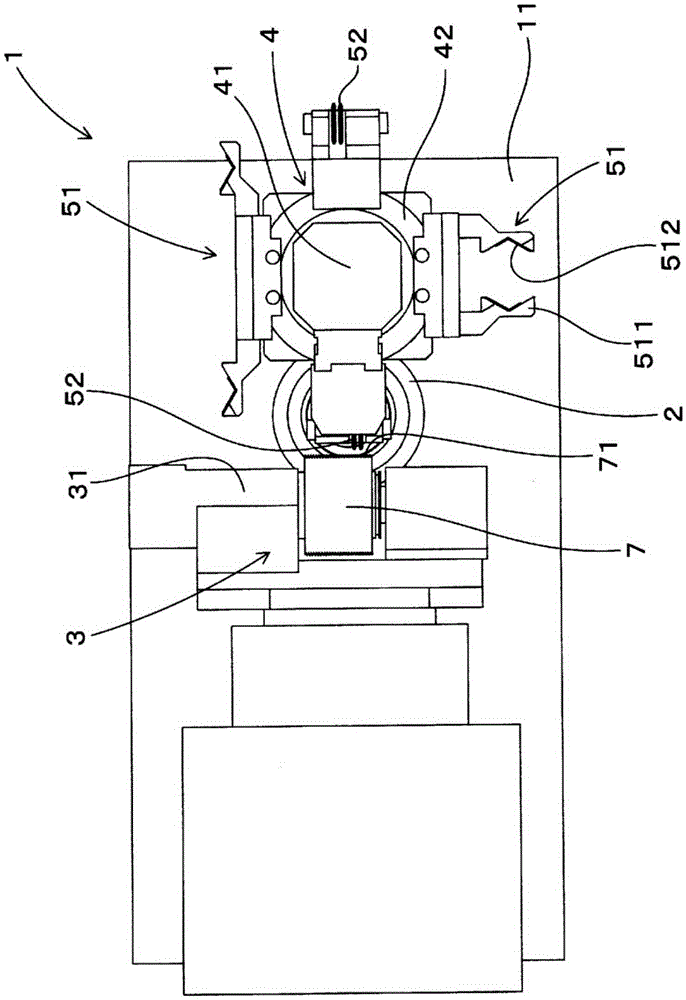

[0038] The rotary processing machine 1 of this example is as figure 1 , figure 2 As shown, it is equipped with: a rotating device 2 that supports and rotates a workpiece 8 formed with a helical tooth 81; A processing device 3 for machining, and a transfer device 4 for loading and unloading a workpiece 8 to and from the rotary device 2 .

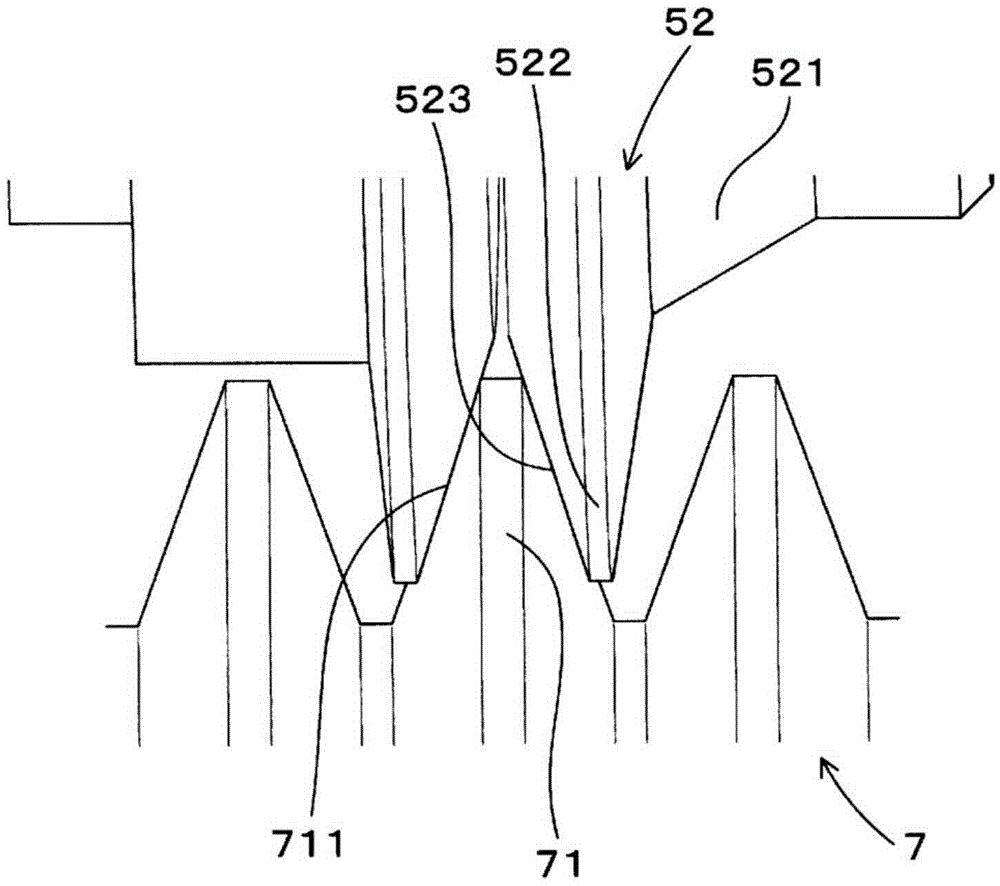

[0039] The conveyance device 4 has a plurality of clamp claws 51 for clamping the workpiece 8 and a dresser 52 for shaping the grinding teeth 71 around the rotation center axis 401 . The conveying device 4 is configured to rotate around the rotation center axis 401 to sequentially bring the gripper claws 51 closer to the rotary device 2 and to make the respective dressers 52 closer to the machining device 3 sequentially. Such as image 3 As shown, the dressing teeth 522 of the respective dress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com