A kind of hot rolling processing method of titanium and titanium alloy seamless oil pipe

The technology of a seamless oil pipe and a processing method is applied in the field of hot rolling processing of titanium and titanium alloy seamless oil pipes, which can solve the problems of increased processing cost, fast consumption of tools and molds, and insufficient power of titanium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

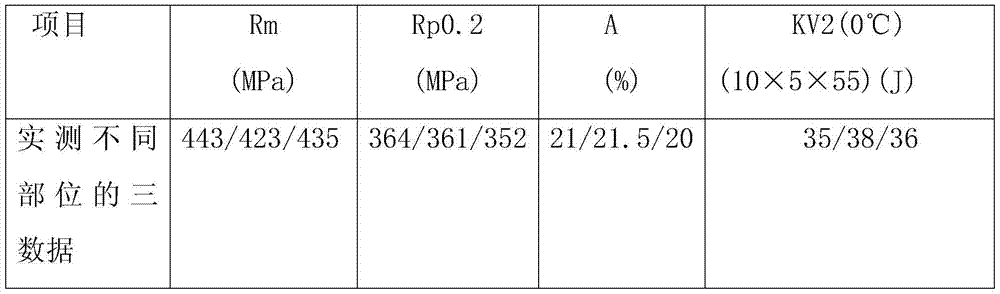

Embodiment 1

[0067] Embodiment 1: adopt TA2 alloy bar, specification is After the anti-oxidation lubricating coating is applied, it is heated to 950°C, and the cross-rolling and piercing is carried out with the above-mentioned setting parameters. The tube blank, preheated spare Mandrel, the surface is coated with SM-B mandrel lubricant and penetrated into the tube blank, and the pressure head is then jacked to prepare the tube There are 8 tube-jacking roll racks, which are coated with anti-oxidation lubricating paint after loosening and stripping, and then heated to 850°C for a second time and kept for 30 minutes. Out of the oven, it is prepared by 6 sets of stretching and reducing frame combination molds Ultrasonic flaw detection of the seamless oil pipe, determine the position of the head defect of the seamless oil pipe and cut the head, after heat treatment at 720°C, straighten after cooling to a temperature below 80°C, and test the mechanical properties of the seamless oil pipe ...

Embodiment 2

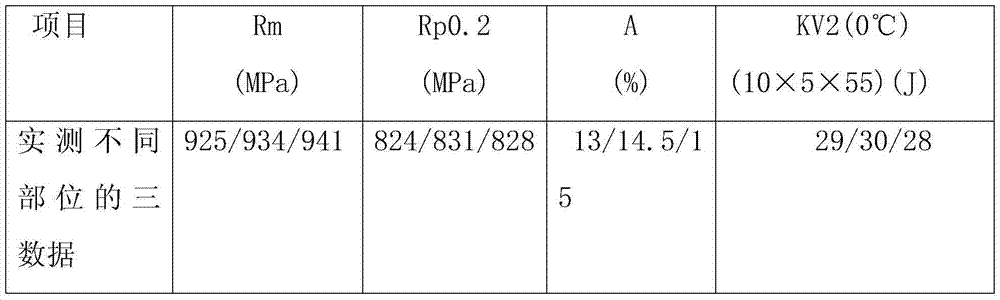

[0071] Embodiment 2: adopt TC4 alloy bar, specification is Heating to 1100°C, using the above set parameters for cross-rolling and piercing to prepare The tube blank, preheated spare Mandrel, the surface is coated with SM-B mandrel lubricant and penetrated into the tube blank, and the pressure head is then jacked to prepare the tube There are 10 pipe rolling and pipe jacking roll stands. After the tube blank is loosened and stripped, it is heated to 950°C for the second time and kept for 30 minutes. The furnace is prepared by 4 tensioning and reducing racks Ultrasonic flaw detection of the seamless oil pipe, determine the defect position of the pipe head and cut the head, heat treatment at 850°C and straighten at 450°C, test the mechanical properties of the seamless oil pipe, and pack it after passing the test.

[0072] The reference mechanical properties of the above TC4 alloy seamless tubing are shown in the table below.

[0073]

[0074] The average value of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com