Metal sheet automatic cutting production line

An automatic cutting and production line technology, applied in metal processing equipment, shearing devices, accessories of shearing machines, etc., can solve the problems of surface coating scratches, substandard products, collision deformation, etc., to avoid friction scratches, The effect of avoiding waste and preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

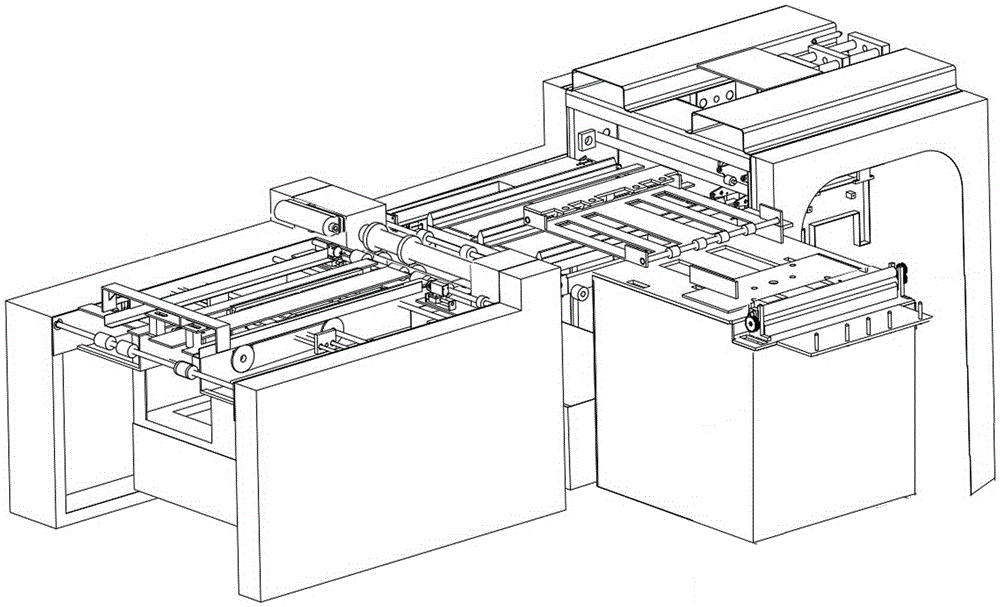

[0027] Such as figure 1 As shown, a metal sheet automatic cutting production line, which includes a conveyor with a calibration device, a compacting and cutting machine, an automatic detection machine and an adsorption blanking machine arranged in sequence, and a transfer table is set downstream of the compacting and cutting machine. The end of the table is connected to the suction blanking machine. The metal sheet is calibrated by the conveyor with the calibration device, sent to the compacting and cutting machine, cut into two parts, and then sent to the suction blanking machine through the conveyor table. The automatic detection machine is set on the conveyor. One side of the table, regularly extract the cut metal sheet for inspection.

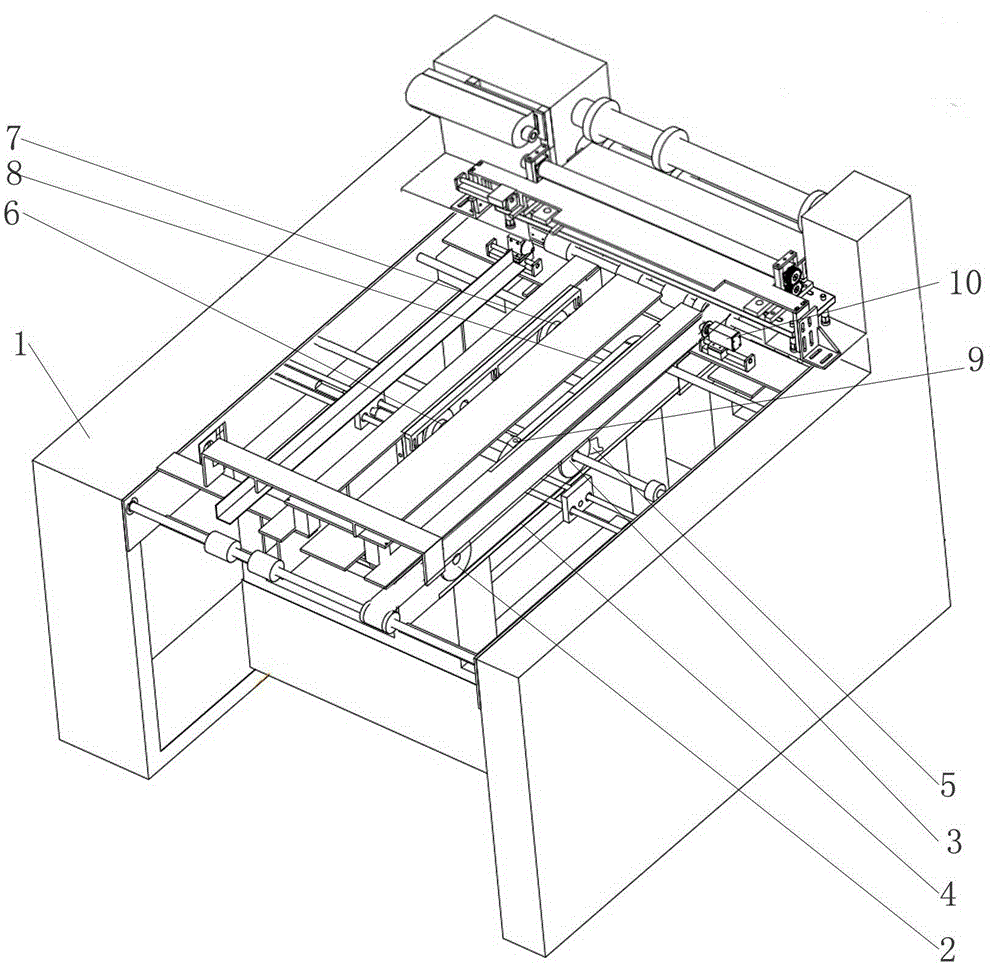

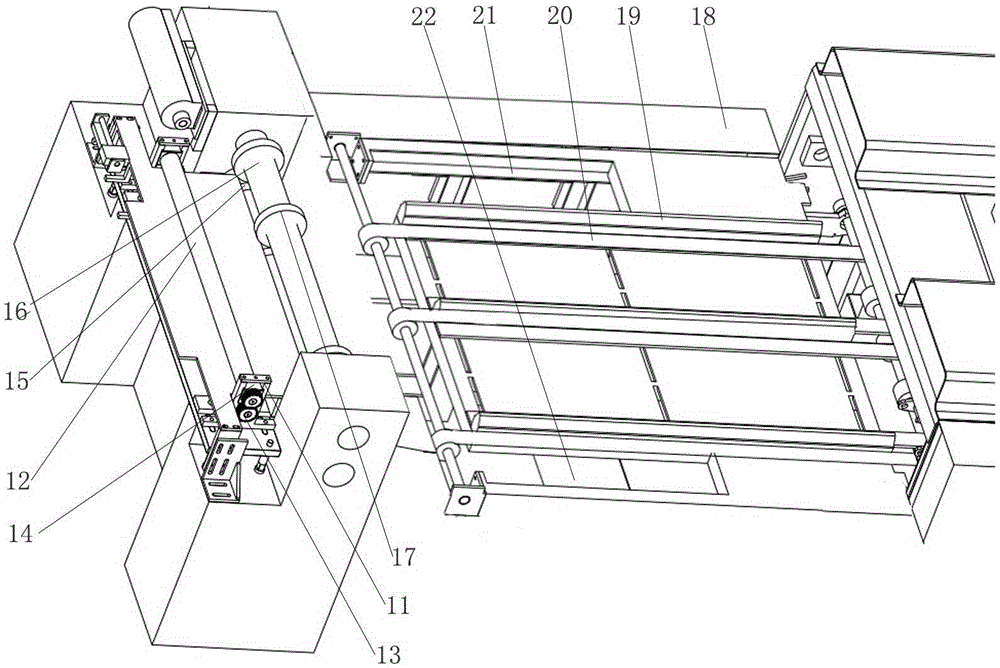

[0028] Such as figure 2 As shown, the two ends of the conveyor frame 1 with the calibration device are respectively provided with a driving shaft and a driven shaft. The driving shaft drives the driven shaft to rotate through the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com