Surface treatment method for nanometer calcium carbonate filled with PVC plastic paste

A nano-calcium carbonate and surface treatment technology, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, coatings, etc., can solve the problems of high yield value of thixotropy, rheological stability, and poor thixotropy, and achieve good results. Economic and social benefits, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

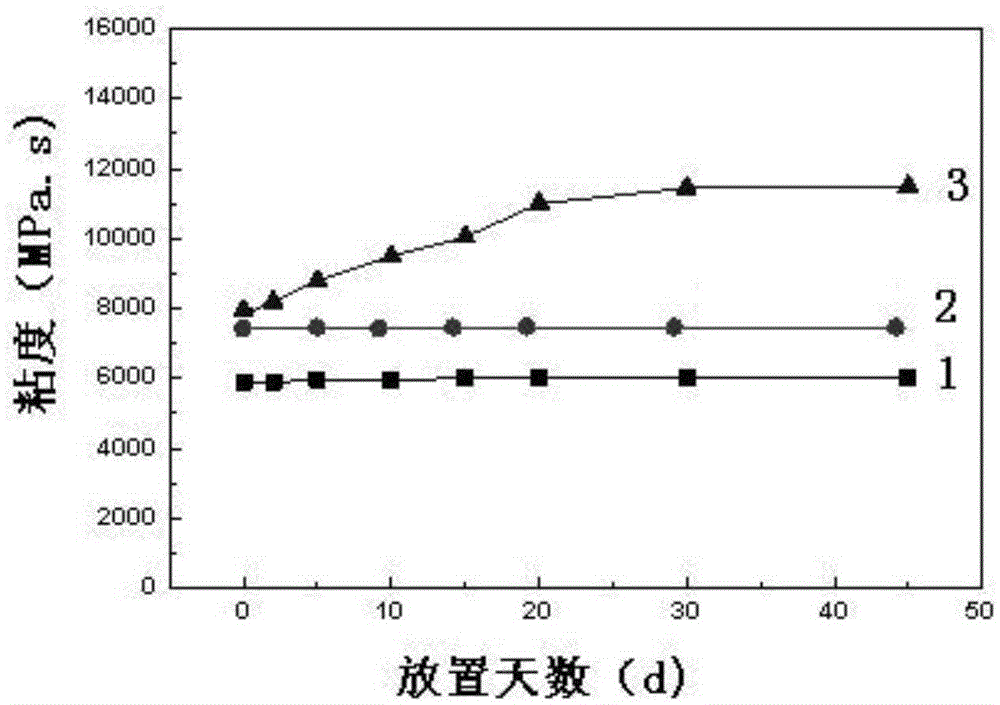

Embodiment 1

[0031] A kind of surface treatment method of the nano-calcium carbonate of filling PVC plastisol, comprises the following steps:

[0032] (1) The specific surface area after carbonation is 21.3m 2 / g of nano-calcium carbonate slurry is transported to the surface treatment tank, the temperature is controlled at 50 ° C, stirred evenly, and nano-calcium carbonate suspension slurry is obtained;

[0033] (2) Adding a surface treatment agent in a stirring state, wherein the addition amount of the surface treatment agent is 2.5% of the dry mass of calcium carbonate, and continuously stirring for 90 minutes to complete the surface modification of nano-calcium carbonate; the surface treatment agent is made of A mass ratio of 1:1 consists of stearic acid and sodium ricinoleic acid methyl sulfate;

[0034] (3) The surface-modified nano-calcium carbonate slurry is dehydrated by pressure filtration, dried with a chain-belt dryer at a drying temperature of 110°C, pulverized, and finally pa...

Embodiment 2

[0037] A kind of surface treatment method of the nano-calcium carbonate of filling PVC plastisol, comprises the following steps:

[0038] (1) The specific surface area after carbonation is 22.8m 2 / g of nano-calcium carbonate slurry is transported to the surface treatment tank, the temperature is controlled at 60 ° C, stirred evenly, and nano-calcium carbonate suspension slurry is obtained;

[0039] (2) Adding a surface treatment agent in a stirring state, wherein the addition of the surface treatment agent is 2% of the dry mass of calcium carbonate, and continuously stirring for 80 minutes to complete the surface modification of nano-calcium carbonate; the surface treatment agent is composed of The mass ratio is composed of arachidic acid and ethyl ricinoleic acid sodium sulfate of 1:2;

[0040] (3) The surface-modified nano-calcium carbonate slurry is subjected to pressure filtration dehydration treatment, dried with a chain-belt dryer at a drying temperature of 100°C, pulv...

Embodiment 3

[0043] A kind of surface treatment method of the nano-calcium carbonate of filling PVC plastisol, comprises the following steps:

[0044] (1) The specific surface area after carbonation is 21.5m 2 / g of nano-calcium carbonate slurry is transported to the surface treatment tank, the temperature is controlled at 70 ° C, stirred evenly, and nano-calcium carbonate suspension slurry is obtained;

[0045] (2) Adding a surface treatment agent in a stirring state, wherein the addition amount of the surface treatment agent is 3.5% of the dry mass of calcium carbonate, and continuously stirring for 70 minutes to complete the surface modification of nano-calcium carbonate; the surface treatment agent is composed of Behenic acid and ethyl ricinoleic acid sodium sulfate are composed of a mass ratio of 1:3;

[0046] (3) The surface-modified nano-calcium carbonate slurry is subjected to pressure filtration dehydration treatment, dried using a chain-belt dryer at a drying temperature of 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap