Load sensing multi-way reversing valve and loader hydraulic control system

A multi-way reversing valve and load sensing technology, which is applied in the field of hydraulic components, can solve the problems of complex structure and high cost of the load sensing multi-way reversing valve, and achieve the goals of improved work efficiency, small pressure loss, and reduced pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation will be described below in conjunction with the accompanying drawings.

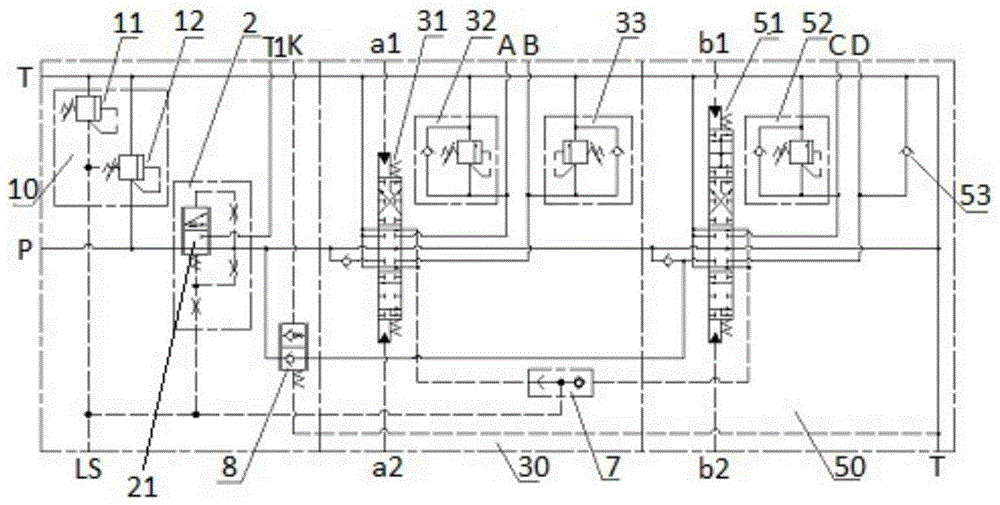

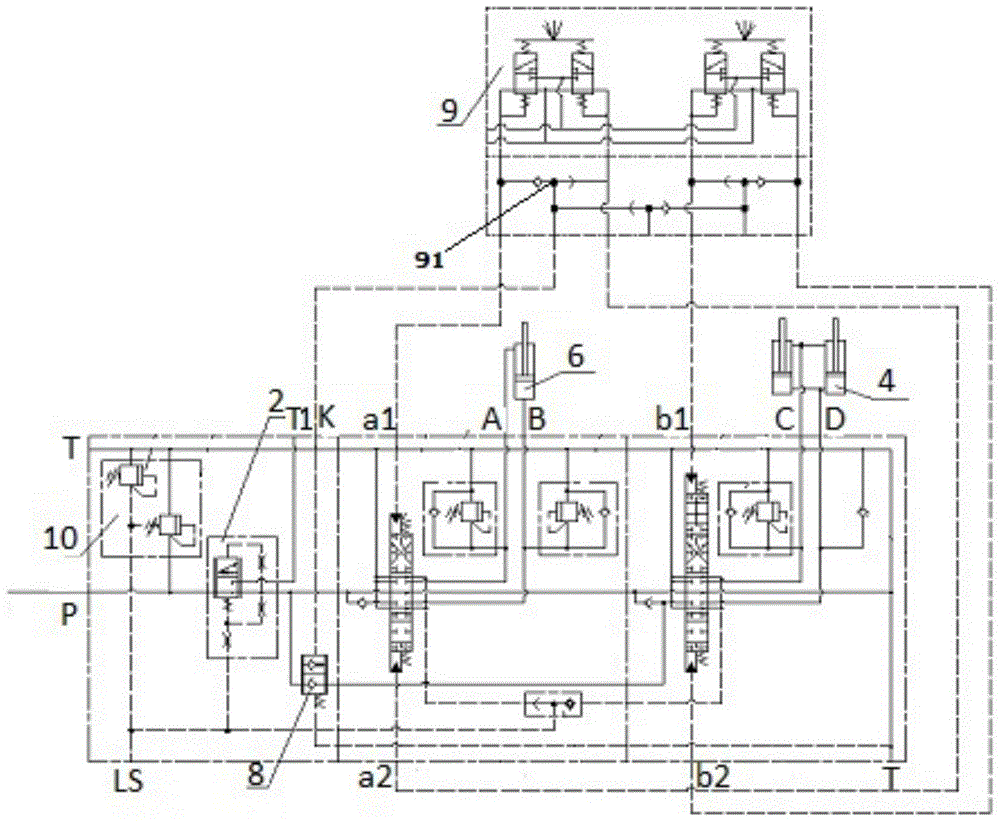

[0024] The load sensing multi-way reversing valve in this embodiment is as figure 1 As shown, it has oil inlet P port, oil return T port, oil return port T1, load signal output LS port, external control K port for communicating with the external oil circuit, and includes pressure compensator 10, pre-valve compensation valve 2 , the flow control valve 8 , the first reversing unit 30 and the second reversing unit 50 . The pressure compensator, pre-valve compensation valve and flow control valve are connected between the first reversing unit, the second reversing unit and the oil inlet port P of the reversing valve;

[0025] The pressure compensator 10 is composed of a relief valve 11 and a differential relief valve 12. The oil inlet of the pressure compensator 10, that is, the oil inlet of the differential relief valve 12 communicates with the oil inlet P port. The oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com