A high-speed quality inspection machine using machine vision inspection

A technology of machine vision inspection and quality inspection machine, which is applied in the direction of instruments, measuring devices, scientific instruments, etc. It can solve the problems of inability to meet the needs of automated production and low efficiency of manual inspection, shorten the focusing time, facilitate clear imaging, and improve yield. The effect of volume speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

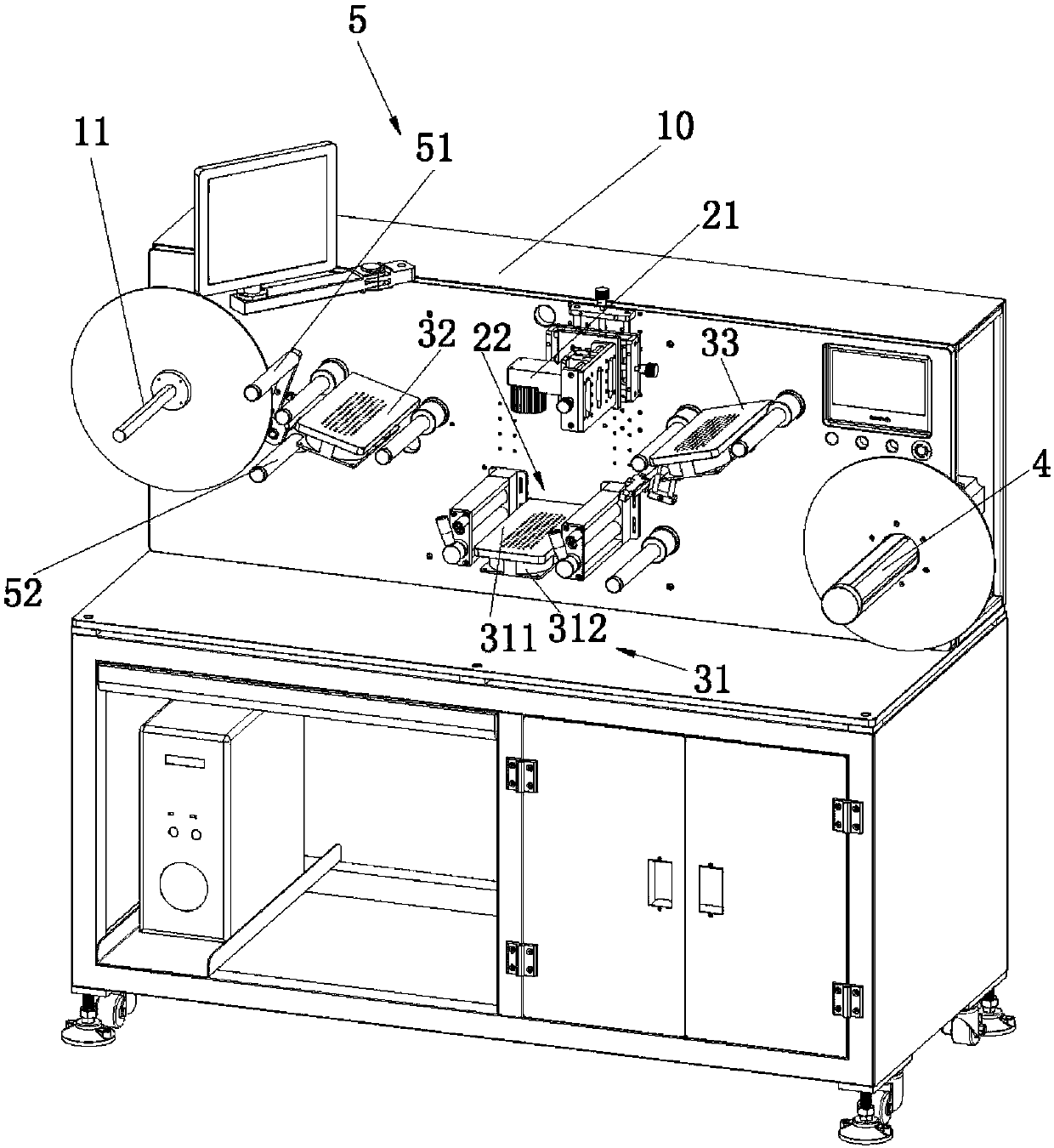

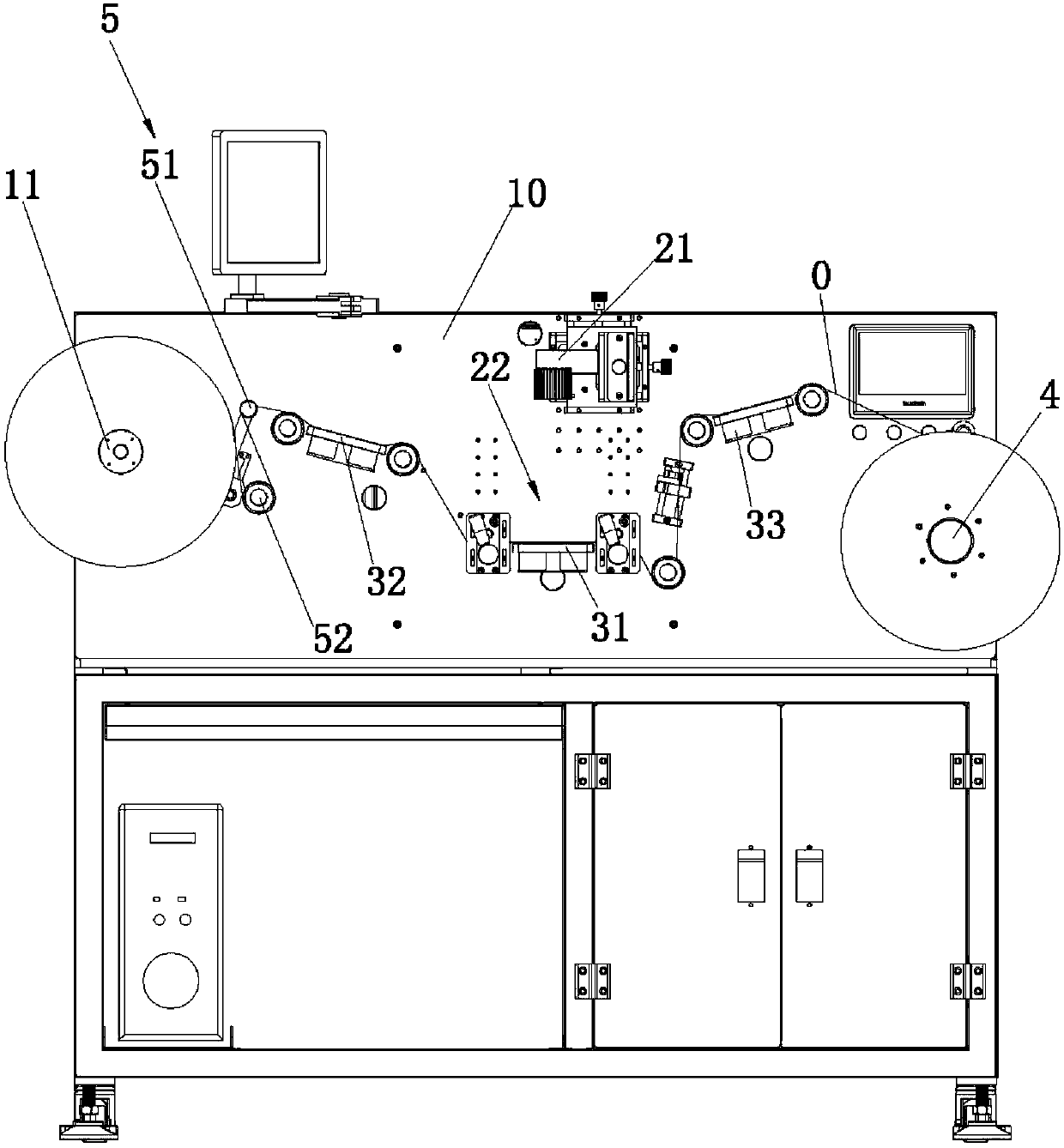

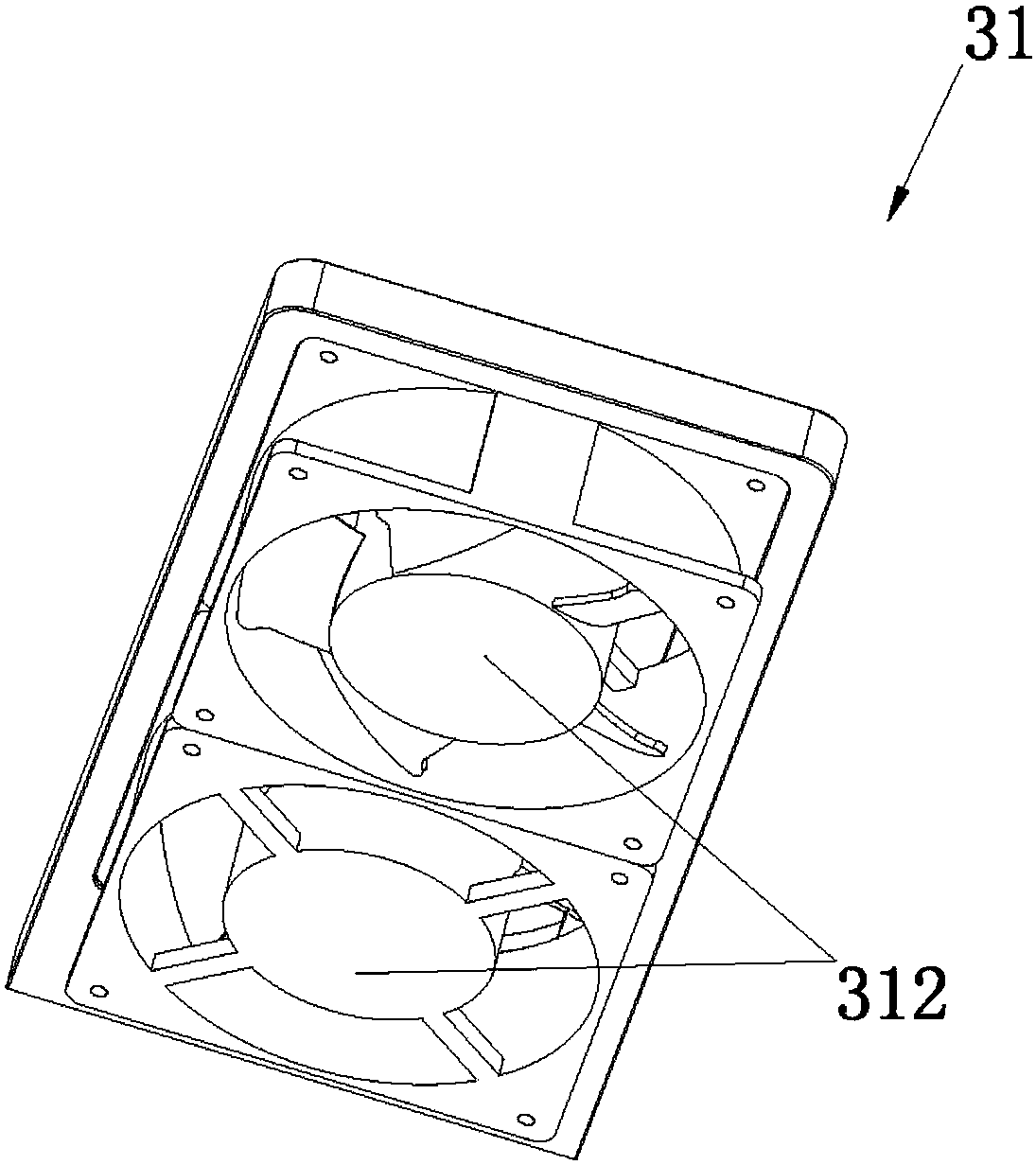

[0039] like figure 1 , 2 As shown, a high-speed quality inspection machine utilizing machine vision detection according to the present invention includes a base frame assembly 10 and an imaging lens 21, and the imaging lens 21 is arranged on the base frame assembly 10, and also includes an imaging station 22 for supporting coil materials The material roll 11, the first material tape suction station 31 and the material receiving roller 4, the imaging lens 21 is arranged on one side of the imaging station 22, and the first material tape suction station 31 is arranged on the other side of the imaging station 22 On the other hand, the winding roller 11 is arranged at one end of the base frame assembly 10 , and the receiving roller 4 is arranged at the other end of the base frame assembly 10 . The code to be detected is attached to the bottom film to form a tape 0, which is wound into a roll and placed on the coil roll 11, and the take-up roll 4 rotates under the drive of an exter...

Embodiment 2

[0049] like figure 1 , 2 , 6, the difference between this embodiment and the first embodiment is that the swing arm assembly 54 includes a long arm 541 and a short arm 542, one end of the short arm 542 is rotatably arranged on the base assembly 10, and the brake band 55 One end of the short arm 542 is fixed to one end of the short arm 542, the other end of the short arm 542 is close to the long arm 541, the pendulum roller 51 is rotatably arranged on one end of the long arm 541, and the other end of the long arm 541 is rotatably arranged on the base frame assembly 10 And arranged between the short arm 542 and the winding roller 11 . When the material belt 0 is pulled by the traction device, under the action of the material belt 0, the long arm 541 swings, and the long arm 541 pushes the short arm 542 to swing, and one end of the short arm 542 loosens the braking band 55, and the winding roller 11 Losing the function of the braking band 55, the winding roller 11 rotates under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com