Five-step iodometric method

A technology of iodometric method and potassium iodide, which is applied in the field of disinfectant detection, can solve the problems of less risk, inconvenience to carry, and long process time for nitrogen gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

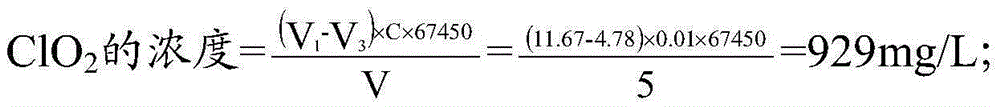

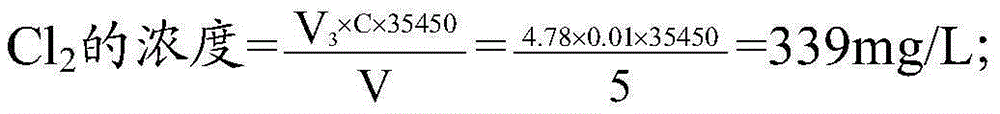

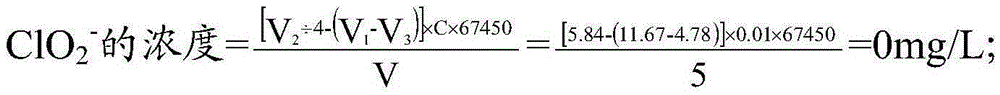

Embodiment 1

[0025] Present embodiment provides a kind of five-step iodometric method, and it comprises the steps:

[0026] 1) Mix 5ml of the sample to be tested with 200ml of water and adjust the pH to 7 with an appropriate amount of phosphate buffer solution (if the pH of the sample is less than 3, first adjust the pH to greater than 3 with sodium hydroxide solution), add 10ml of 100g / L After the potassium iodide solution, titrate with a sodium thiosulfate standard solution with a concentration of 0.01mol / L until the mixed solution turns light yellow, add 1ml of a starch solution with a concentration of 5g / L, the solution turns blue, continue to titrate thiosulfuric acid Sodium standard solution until the blue color disappears, the volume of the added sodium thiosulfate standard solution is recorded as V1, and V1 is 11.67ml in the present embodiment;

[0027] 2) Gradually add 2ml of hydrochloric acid solution with a concentration of 2.5N to the solution obtained in step 1), adjust the mi...

Embodiment 2

[0053] Present embodiment provides a kind of five-step iodometric method, and it comprises the steps:

[0054] 1) Mix 2ml of the sample to be tested with 50ml of water and adjust the pH to 7 with an appropriate amount of phosphate buffer solution (if the pH of the sample is less than 3, first adjust the pH to greater than 3 with sodium hydroxide solution), add 8ml of 100g / L After the potassium iodide solution, titrate with a standard solution of sodium thiosulfate with a concentration of 0.01mol / L until the mixed solution turns light yellow, add 0.8ml of a starch solution with a concentration of 5g / L, the solution turns blue, and continue to titrate the thiosulfate solution. Sodium sulfate standard solution until the blue color disappears, the volume of the added sodium thiosulfate standard solution is recorded as V1, and V1 is 4.67ml in the present embodiment;

[0055] 2) Gradually add 2ml of hydrochloric acid solution with a concentration of 2.5N to the solution obtained in ...

Embodiment 3

[0067] Present embodiment provides a kind of five-step iodometric method, and it comprises the steps:

[0068] 1) Mix 5ml of the sample to be tested with 300ml of water and adjust the pH to 7 with an appropriate amount of phosphate buffer solution (if the pH of the sample is less than 3, first adjust the pH to greater than 3 with sodium hydroxide solution), add 20ml of 100g / L After the potassium iodide solution, titrate with a standard solution of sodium thiosulfate with a concentration of 0.1mol / L until the mixed solution turns light yellow, add 1.5ml of starch solution with a concentration of 5g / L, the solution turns blue, and continue to titrate the thiosulfate solution. Sodium sulfate standard solution until the blue color disappears, the volume of the added sodium thiosulfate standard solution is recorded as V1, and V1 is 1.17ml in the present embodiment;

[0069] 2) Gradually add 5ml of hydrochloric acid solution with a concentration of 2.5N to the solution obtained in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com