Low-voltage wide-speed adjustment permanent magnet synchronous motor

A permanent magnet synchronous, wide speed regulation technology, applied in synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc. Poor environmental applicability and other problems, to achieve the effects of reliable performance, good low-speed stability, and small torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

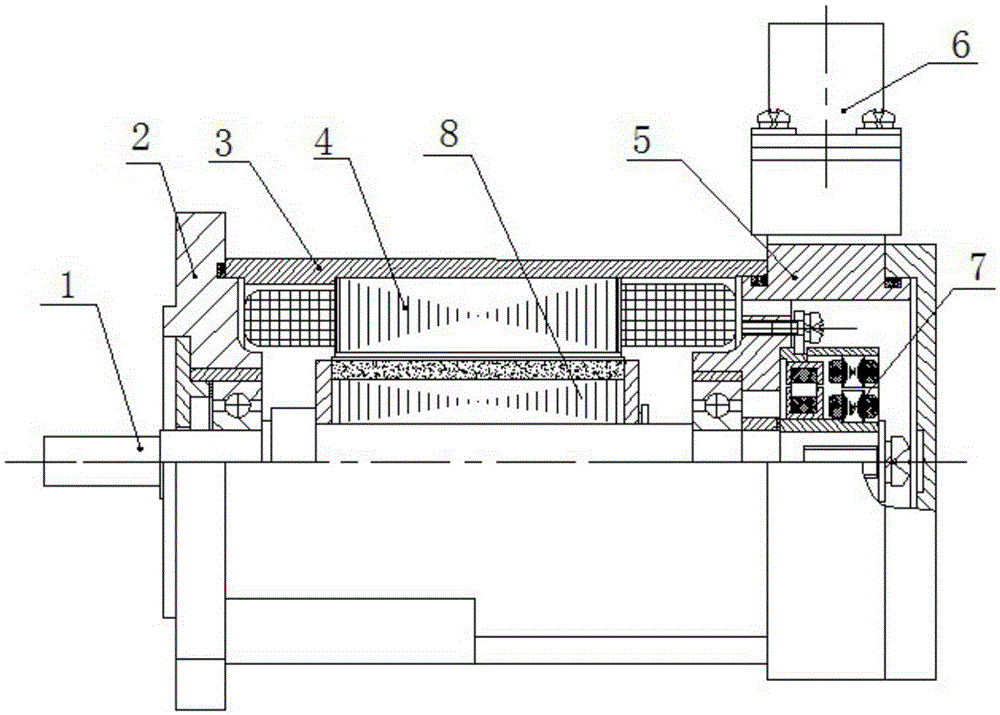

[0014] Example: figure 1 is a schematic diagram of the motor structure according to an embodiment of the present invention. This embodiment describes a low-voltage wide-speed adjustable permanent magnet synchronous motor, including: a casing 3, an armature 4, a motor rotor 8 and a feedback element 7, and a front end cover 2, The rear end cover 5, the casing 3 is provided with an output shaft 1, and the end of the output shaft 1 protrudes from the casing 3, and the feedback element 7 is in close contact with the output shaft 1, wherein, The rotor magnet of the motor is of an eccentric structure, and the generated air-gap magnetic field is sinusoidally distributed.

[0015] In this embodiment, through the eccentric design of the magnetic steel structure of the motor rotor 8, a special structure and winding form are adopted, which not only ensures that the magnetic density of the yoke is in a controlled range under rated and overload conditions, but the eccentric structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com