Single-winding bearingless motor torque and suspension force direct controller and construction method

A bearingless motor and suspension force technology, which is applied in the direction of motor generator control, electronic commutation motor control, electromechanical brake control, etc., can solve the problems of current fluctuation, complicated switching tube control process, and large power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

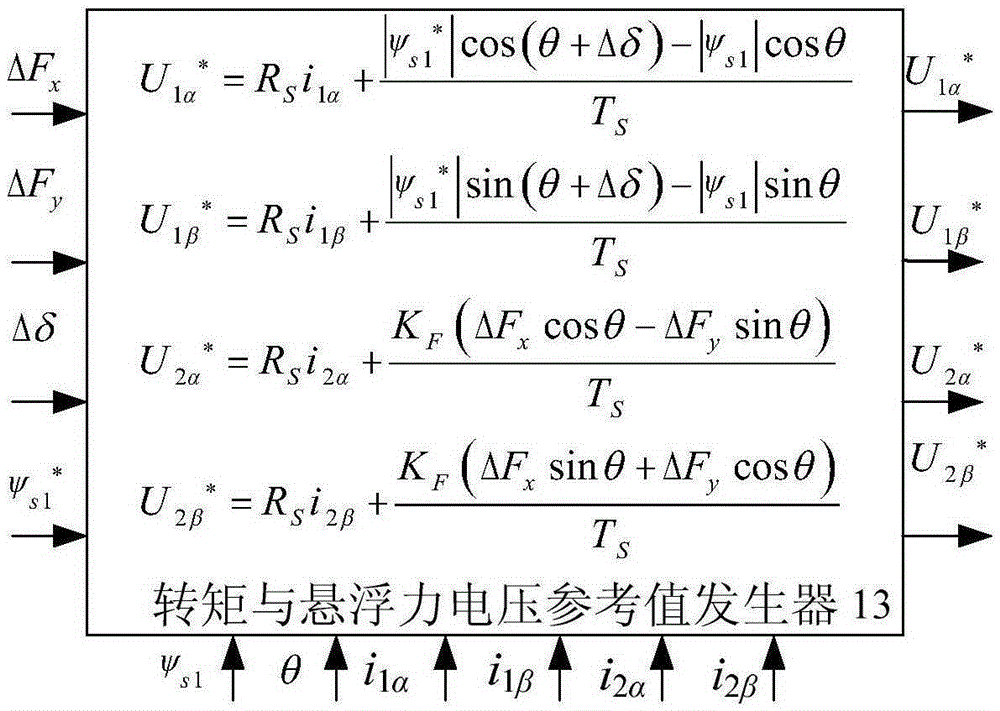

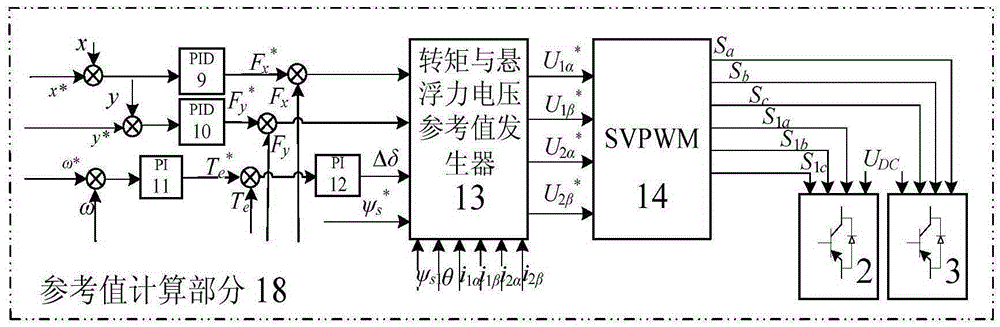

[0031] Figure 7 What is shown is a schematic diagram of the composition of the direct controller 20 of torque and levitation force of a complete single-winding double-three-phase bearingless permanent magnet motor. The torque and suspension force direct controller 20 is composed of a reference value calculation part 18 and an observed value calculation part 19 .

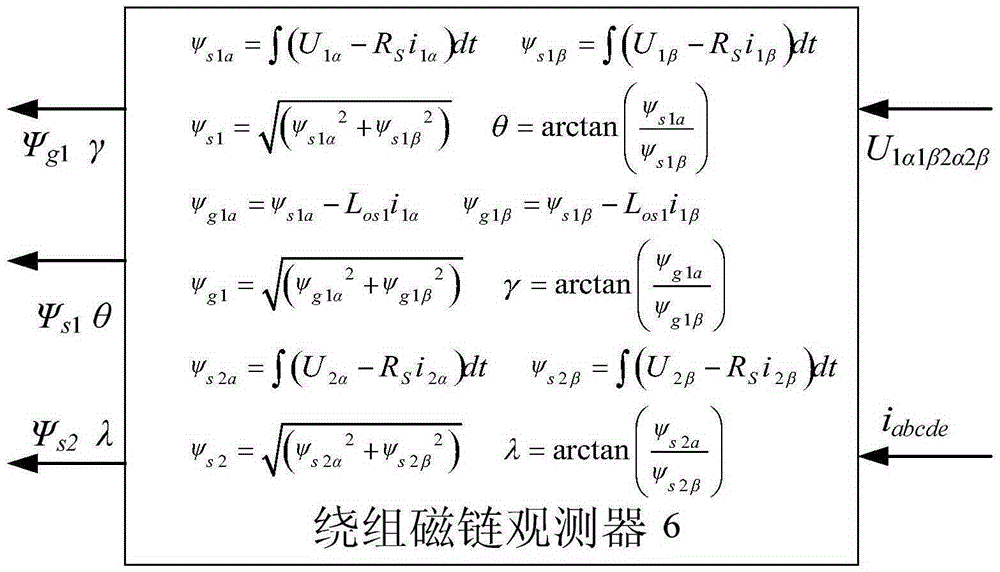

[0032] The observed value calculation part 19 is composed of a winding flux observer 6, a levitation force observer 7, a torque observer 8 and two matrix transformation modules 4, 5, wherein the output of the matrix transformation module 4 is connected to the winding flux linkage The input of the observer 6 and the output of the winding flux observer 6 are respectively connected to the levitation force observer 7 and the torque observer 8, and the output of the matrix transformation module 5 is respectively connected to the winding flux observer 6 and the torque observer 8. Suspension force observer 7 respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com