Receiver and manufacturing method

A receiver and shell technology, which is applied in the manufacture/assembly of earphones, receivers/earphone accessories, etc., can solve the problems of simplifying the manufacturing process and unfavorable receivers, and achieve the effects of simplifying the manufacturing process, reducing volume, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

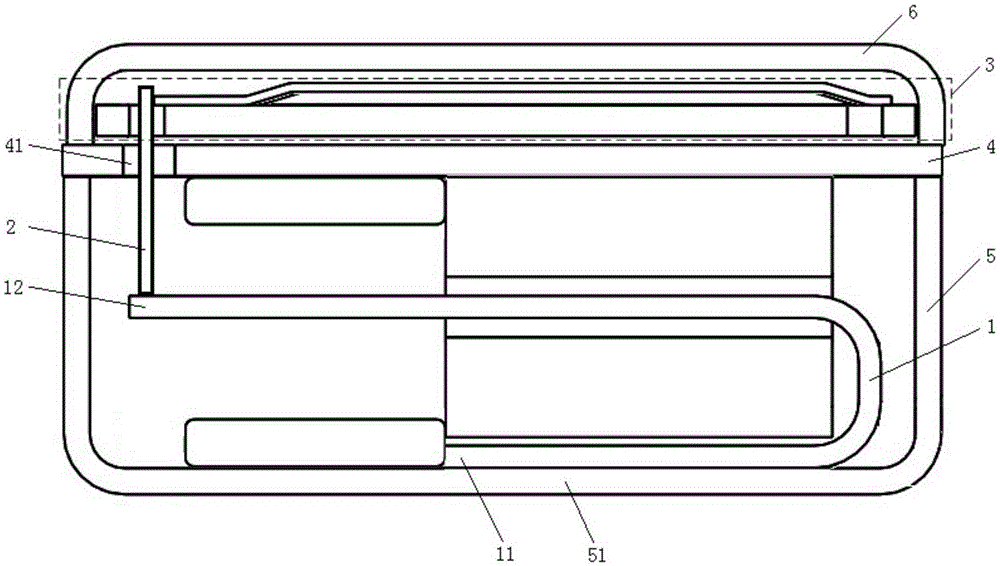

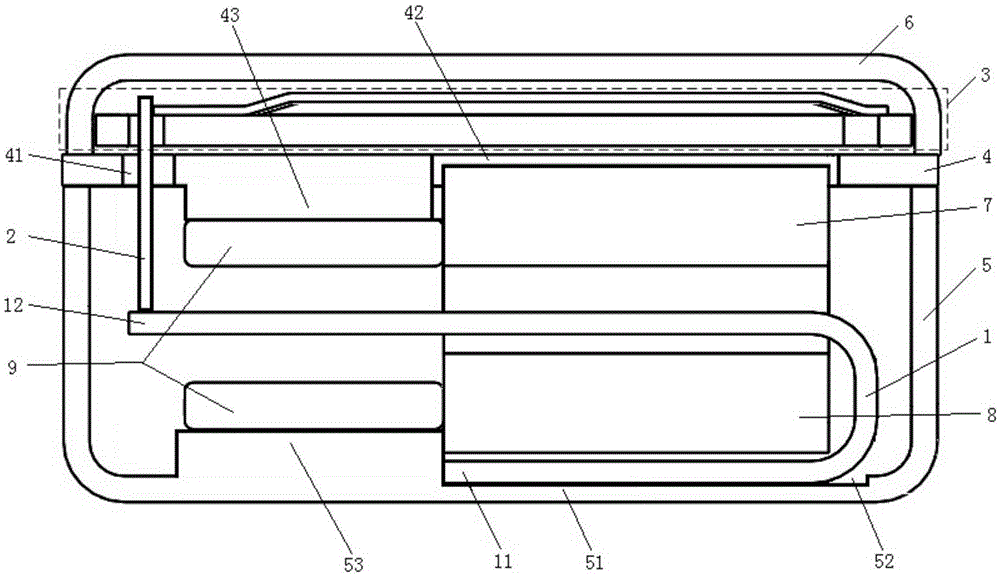

[0046] This embodiment provides a receiver, such as figure 1 As shown, it includes a U-shaped balanced armature 1 , a power transmission rod 2 , a diaphragm mechanism 3 , a middle-layer partition 4 , a lower shell 5 and an upper shell 6 .

[0047] The upper surface of the middle-layer partition 4 is sealedly connected with the upper shell 6 of the outer shell, and the lower surface of the middle-layer partition 4 is sealed with the lower shell 5 of the outer shell; Closed loop, can also be used as the iron core in the magnetic drive mechanism. Preferably, the materials of the above-mentioned middle-layer separator 4 and the lower shell 5 are soft magnetic materials, such as silicon steel sheet, soft ferrite, amorphous alloy, permalloy and other materials.

[0048] The U-shaped balance armature 1 includes two parallel arms. The first parallel arm 11 is fixedly connected to the bottom 51 of the lower shell 5 of the outer shell. The second parallel arm 12 of the U-shaped balance...

Embodiment 2

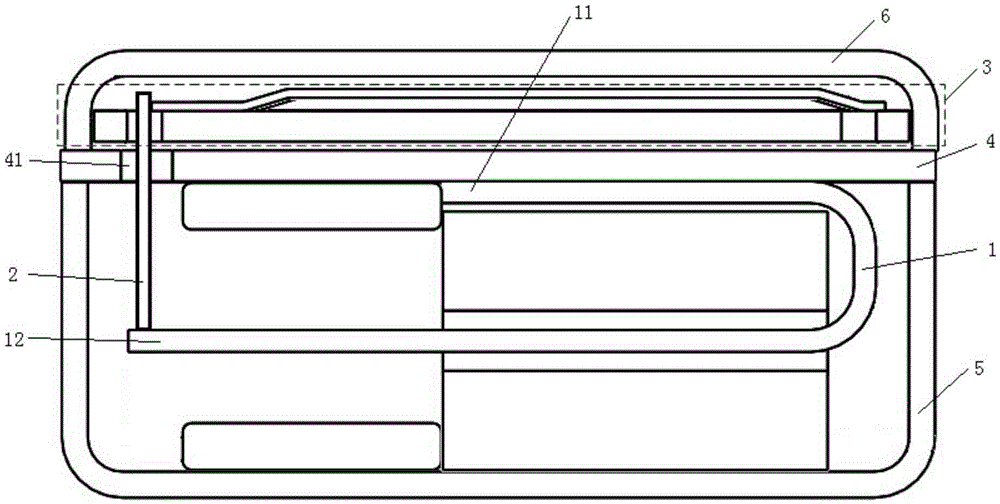

[0062] This embodiment provides a receiver, such as image 3 As shown, it includes a U-shaped balanced armature 1 , a power transmission rod 2 , a diaphragm mechanism 3 , a middle-layer partition 4 , a lower shell 5 and an upper shell 6 .

[0063] The upper surface of the middle-layer partition 4 is sealedly connected with the upper shell 6 of the outer shell, and the lower surface of the middle-layer partition 4 is sealed with the lower shell 5 of the outer shell; Closed loop, can also be used as the iron core in the magnetic drive mechanism.

[0064] The U-shaped balance armature 1 includes two parallel arms, the first parallel arm 11 is fixedly connected to the middle partition 4 , and the second parallel arm 12 of the U-shaped balance armature 1 is suspended in the middle partition 4 and the lower shell 5 of the outer shell. The enclosed first hollow cavity.

[0065] The diaphragm mechanism 3 is located in the second hollow cavity enclosed by the middle-layer partition p...

Embodiment 3

[0074] This embodiment provides a method for making a receiver, and the method is applied to, for example, making a receiver such as figure 1 and 2 receivers shown, such as Image 6 As shown, the method includes the following steps:

[0075] S1, including:

[0076] S1-1: Position and install the first parallel arm 11 of the U-shaped balance armature 1 on the bottom 51 of the lower casing 5 of the outer casing.

[0077] S1-2: Then, one end of the power transmission rod 2 is positioned and installed on the end of the second parallel arm 12 of the U-shaped balance armature 1 .

[0078] S1-3: Then, cover the opening of the lower shell 5 with the middle-layer partition 4, and seal the connection with the lower shell 5 of the outer shell.

[0079] S1-4: The lower part of the receiver is then finished.

[0080] S2, including:

[0081] S2-1: Position and install the diaphragm mechanism 3 in the upper casing 6 of the outer casing.

[0082] S2-2: The fabrication of the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com