Device for heat treatment of coated semifinished steel products

A semi-finished and coating technology, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve problems such as stamping tool wear, impact on surface quality of parts and paint adhesion, and cracks on parts, and achieve the effect of preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

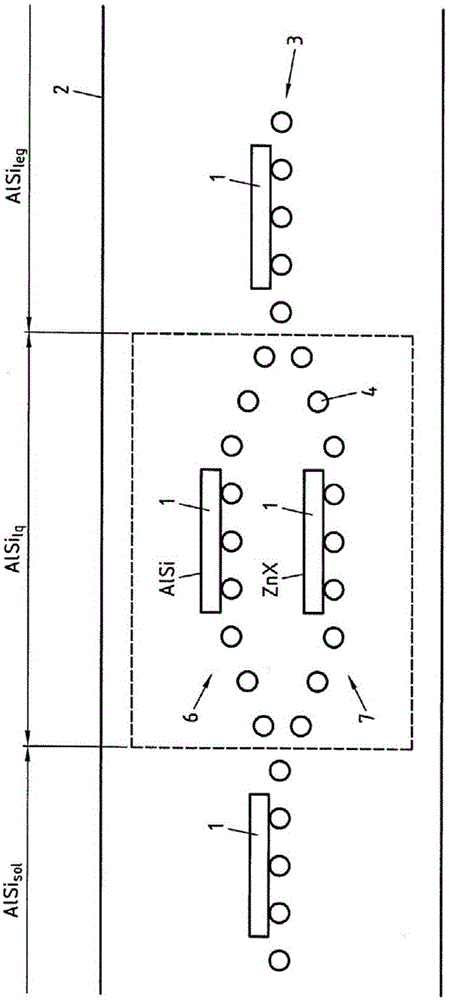

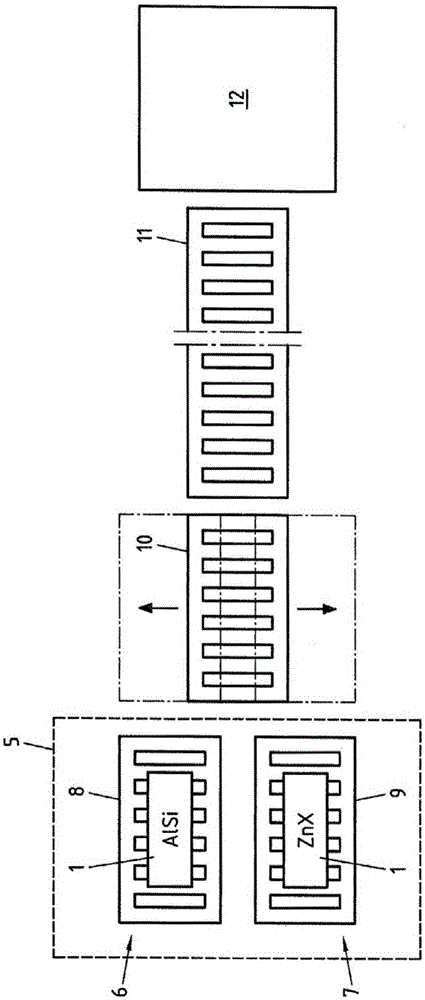

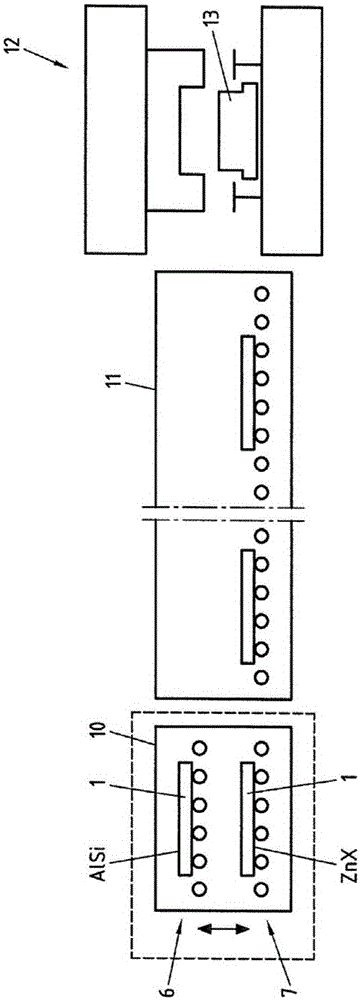

[0027] The device for heat treatment of coated steel semi-finished product 1 according to the present invention has a continuous furnace 2 (only in figure 1 Shown in). Here, a conveying device 3 for the semi-finished steel product 1 is shown, which has a roller 4 as a conveying element. As shown in the figure, the semi-finished steel product 1 is placed on the roller 4 in a continuous furnace. The semi-finished steel product 1 is to be austenitized into an intermediate product for direct pressure hardening, and has the form of a blank.

[0028] According to the invention, the branch section 5 of the continuous furnace 2 has two conveying element groups 6,7. Here, each of the conveying element groups 6, 7 has a plurality of conveying elements designed as rollers 4, and in the branch portion 5, the steel semi-finished product 1 or is placed on the conveying elements of the first conveying element group 6, Or it is placed on the conveying element of the second conveying element gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com