Stepped coop

A step-type, chicken cage technology, applied in poultry cages or houses, applications, poultry industry, etc., can solve the problems of troublesome adjustment, high cost, cumbersome operation process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

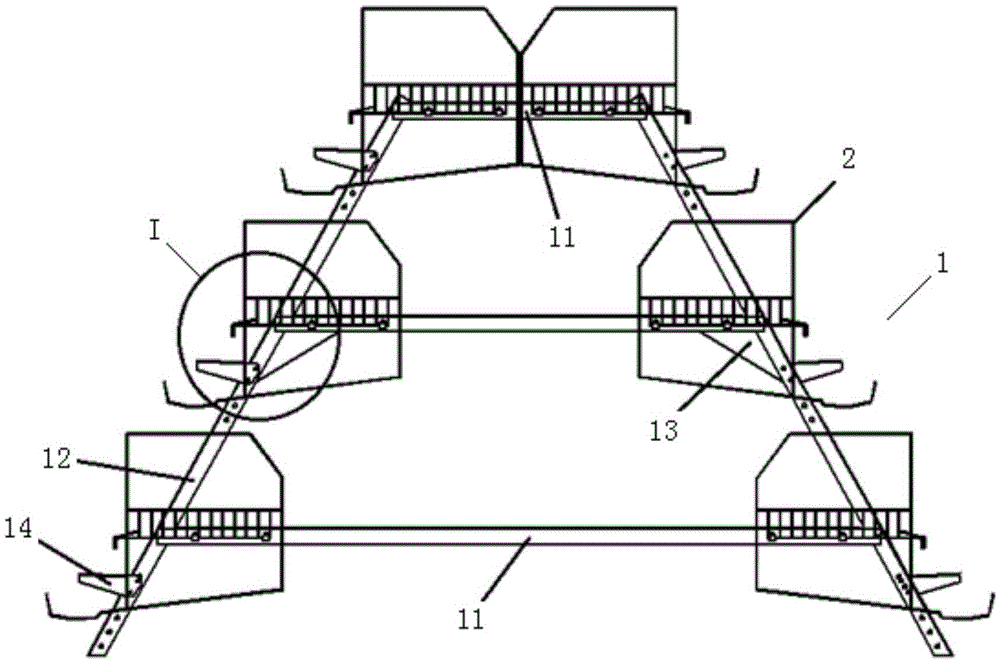

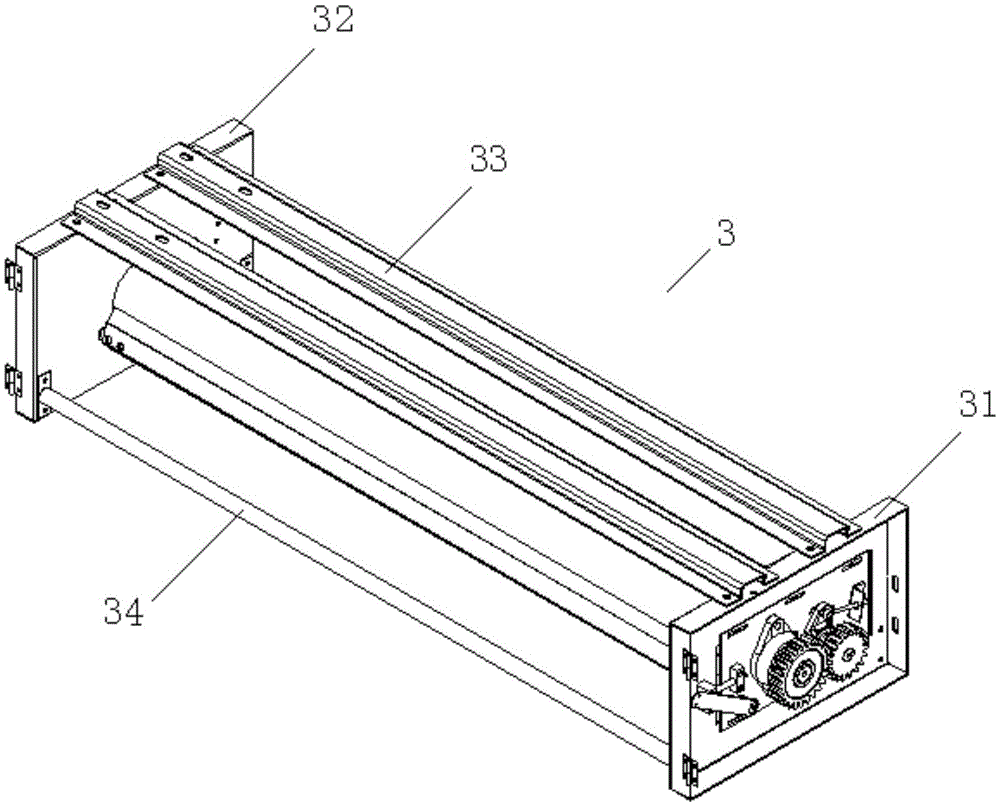

[0038] The stepped chicken cage equipment of the present invention includes a plurality of stepped disassembly and assembly cage frames 1, and adjacent stepped disassembly and assembly cage frames 1 are connected by a plurality of cage frame beams, and the cage frame beams are connected by the upper The lower part is arranged in a stepped manner, and the structure formed by the stepped disassembly and assembly cage frame 1 and the cage frame cross beam is provided with a plurality of cage nets 2; and includes a manure cleaner 3 set at one end of the chicken cage equipment, and includes A manure belt tensioning device 4 connected to the manure cleaner 3 through a manure belt 46 at the other end of the chicken cage equipment.

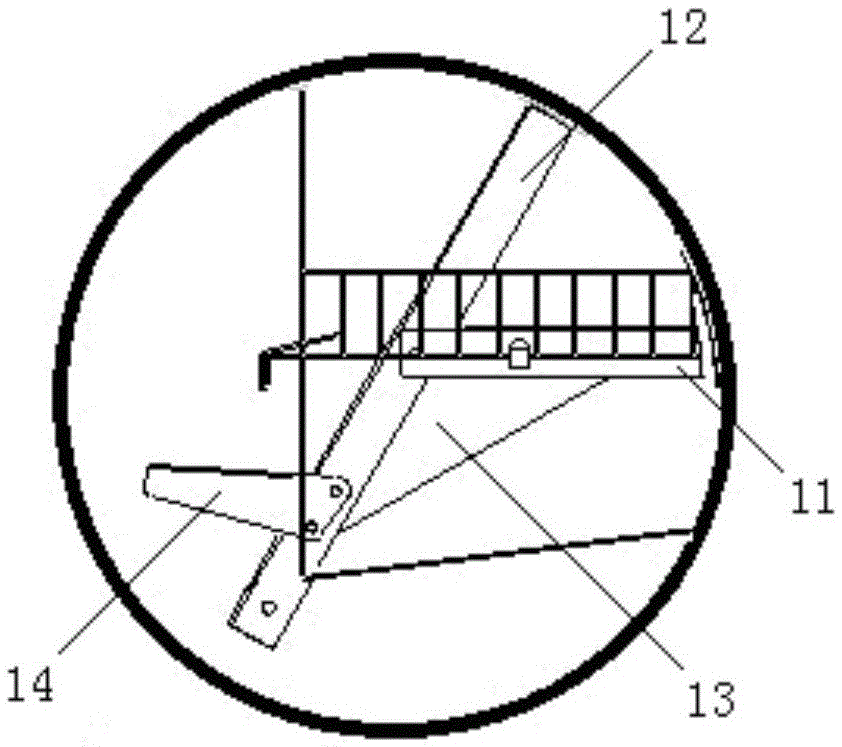

[0039] As attached figure 1 , 2 As shown, in this embodiment, the stepped disassembly and assembly cage 1 includes cage legs 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com