A thermal vacuum drying device and a pressure balancer provided with a pressure balancer

A drying device and thermal vacuum technology, which can be applied to the device for coating liquid on the surface, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as uneven pressure of vacuum branch pipes, uneven local pressure, and air flow disorder , to achieve the effect of reducing MURA phenomenon, improving film quality and constant airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

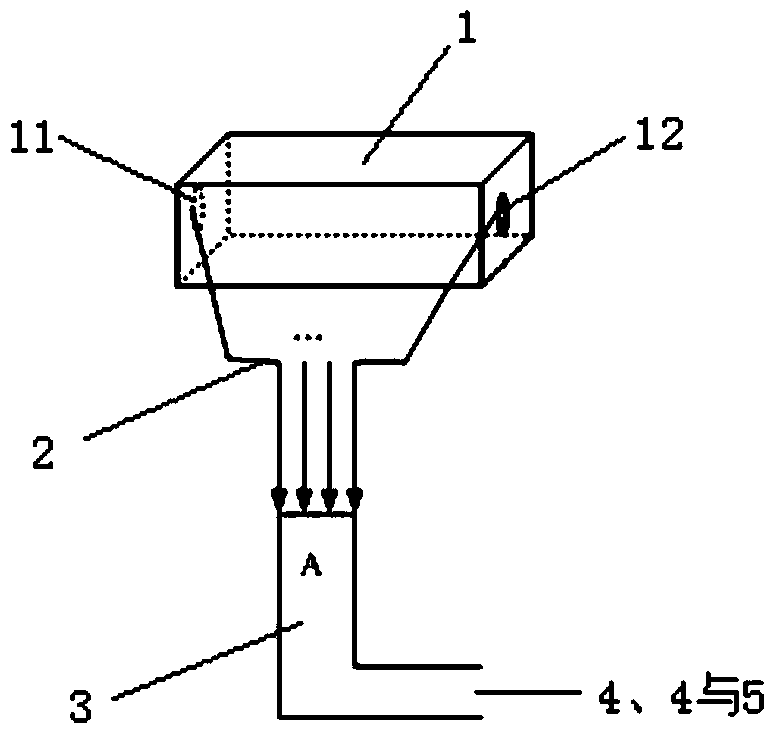

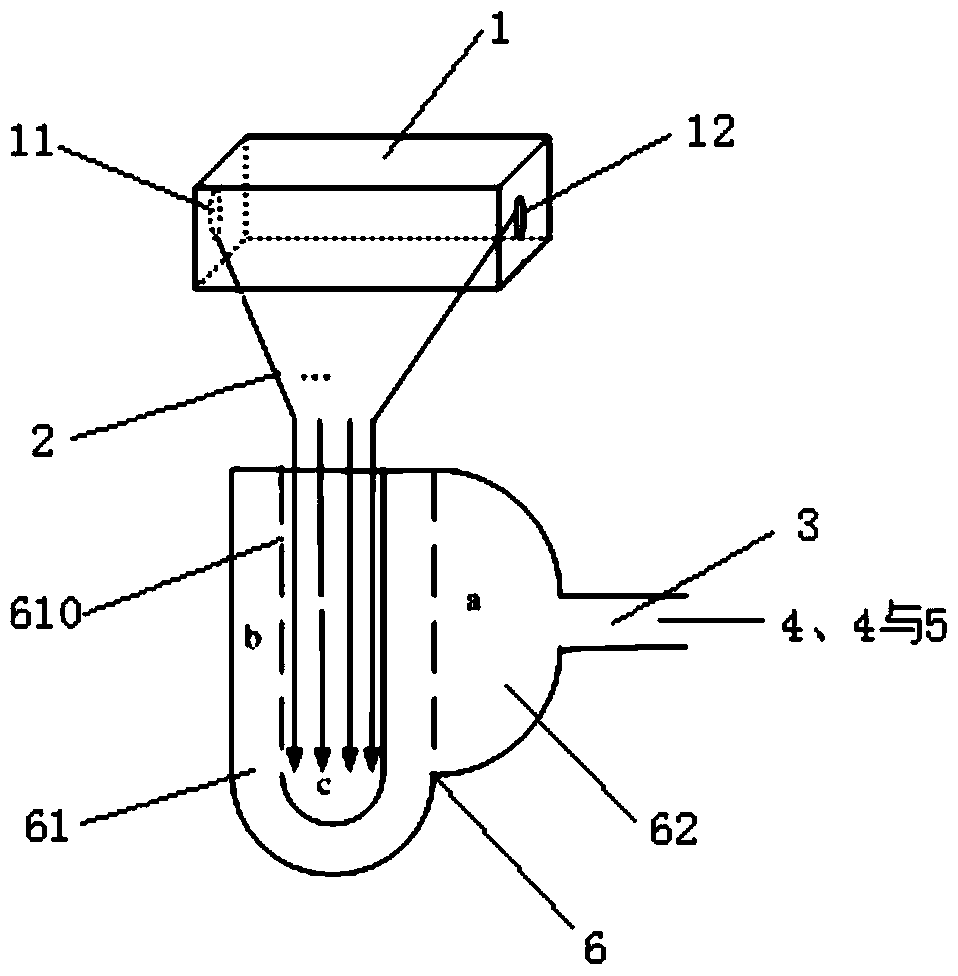

[0022] Such as figure 1 , 2 As shown, the present embodiment provides a thermal vacuum drying device, comprising a chamber 1, on both sides of the chamber 1 are provided with vacuum suction ports 11, 12, and one end of the vacuum branch pipe 2 is connected to the vacuum suction ports 11, 12 12. The other end merges with one end of the vacuum main pipeline 3, and the other end of the vacuum main pipeline 3 is connected to the vacuum pump unit 4 (not shown in the figure), or connected to the vacuum pump unit 4 and the solvent trap unit 5 (not shown in the figure). As shown in the assembly unit of ), a pressure balancer 6 is provided at the confluence of the vacuum branch pipeline 2 and the vacuum m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com