Roller frame, automatic spinning equipment and the application of the equipment

A technology of spinning equipment and roller frame, which is applied in the field of spinning equipment, can solve the problems of blackened spinning of collar parts, product scrapping, difficulties, etc., and achieve the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

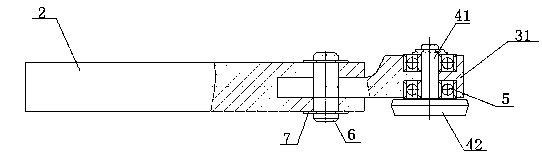

[0037] This embodiment provides a roller frame, such as image 3 and Figure 4 As shown, the roller frame 3 is a "Y"-shaped structure with two symmetrical protrusions 31, and angular contact bearings 5 and rolling wheels 4 are respectively installed in the protrusions 31; the rolling wheels 4 include rollers 41 and roller 42; the angular contact bearing 5 is installed in the roller frame 3, the rolling wheel 4 is installed in the inner hole of the angular contact bearing 5, and the roller 42 extends out of the roller frame 3.

[0038]Two angular contact bearings 5 are installed in each of the protrusions 31 .

[0039] Each of the angular contact bearings 5 can move up and down along the axis of rotation of the workpiece in the roller frame 3, and the setting of the movement gap is less than 0.03mm.

[0040] During spinning, the two rolling wheels 4 are symmetrical with respect to the rotation axis of the workpiece, and the axis of the roller 41 deviates from the rotati...

Embodiment 2

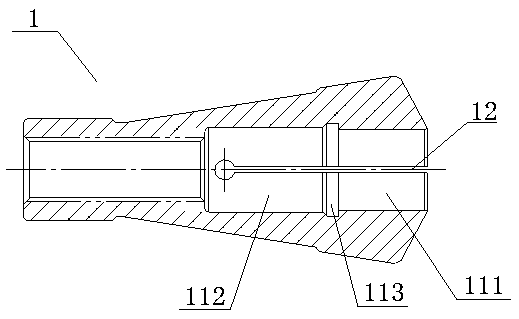

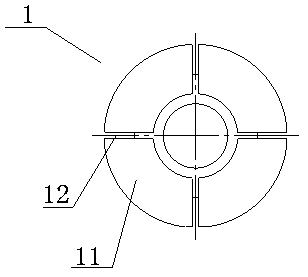

[0043] This embodiment provides an automatic spinning equipment, such as Figure 1~5 As shown, the spinning equipment includes an elastic bushing 1, a knife seat, a knife bar 2, a roller frame 3 and a rolling wheel 4 described in Embodiment 1; the elastic bushing 1 includes a blade 11, and the blade 11 An elastic groove 12 is arranged between them, and a clamping hole 111, an elastic cavity 112, and a transition zone 113 connecting the clamping hole 111 and the elastic cavity 112 are opened in the blade 11; the rolling wheel 4 includes a roller 41 and a roller 42 ; One end of the knife bar 2 is connected with the knife seat, and the other end of the knife bar 2 is connected with a roller frame 3; Angular contact bearing 5 and described rolling wheel 4 are installed respectively; Described angular contact bearing 5 is installed in the roller frame 3, as figure 2 and Figure 5 as shown, Figure 5 Among them, 8 is a bearing installation hole, and 9 is a pin installation hole;...

Embodiment 3

[0058] This embodiment provides a preferred application of the automatic spinning equipment described in the present invention. This embodiment uses the automatic spinning equipment described in the embodiment to spin the collar on the gear shaft of the casing in the column power steering gear on, such as Figure 6 The schematic diagram of the combined structure of the middle shell is shown. Figure 6 Among them, the middle housing assembly includes the middle housing 100, the bearing 101, the collar 102 and the gear shaft 103. The spinning equipment of the present invention can solve the problem of the middle housing assembly, and the bearing 101 tightly clamps the gear shaft 103. It lives on the installation end face of the middle casing 100, so that the gear shaft combination is in the working state, and there is no axial movement and dislocation between the gear shaft and the middle casing 100, so as to avoid abnormal noise and failure of the column booster. The spinning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com