Composite spinning forming device and process for clutch shell with internal longitudinal teeth

A clutch housing and composite spinning technology, which is applied in the field of composite spinning forming equipment and technology for inner longitudinal gear clutch housings, can solve the problems of low processing efficiency and material utilization, inability to realize non-penetrating gear processing, and fatigue impact resistance Weak performance and other problems, to achieve the effect of high material utilization, strong flexibility, and low tonnage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

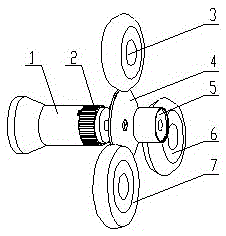

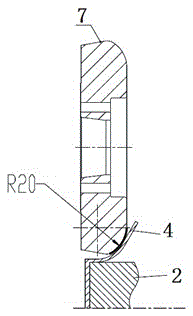

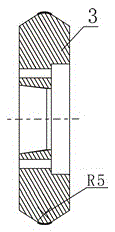

[0026] Embodiment 1: see Figure 1 to Figure 5 , a composite spinning forming equipment for a clutch housing with internal longitudinal teeth, comprising a main shaft 1, a mandrel 2, and a tail top 5 arranged coaxially in sequence, one end of the mandrel 2 is installed on the main shaft 1, and the other end is provided with The positioning shaft of the blank 4 is installed, and the outer wall of the mandrel 2 is uniformly distributed with outer longitudinal teeth along the axial direction. The mandrel 2 is provided with end face teeth on one end of the positioning shaft, and the middle part of the tail top 5 is provided with a through hole, through the through hole and The positioning shaft is detachably connected; the first rotary wheel 7, the second rotary wheel 3 and the third rotary wheel 6 are arranged on the outer side of the tail top 5, and the rotary axes of the three rotary wheels are set along the axial direction of the main shaft 1, and can be connected with the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com