A Cutting Tool for Machining Right Angle and Obtuse Angle Edge in Shallow Blind Hole

An edge processing and right-angle technology, which is used in the processing of right-angled and obtuse-angled edges in shallow blind holes, can solve the problems of design and processing difficulties, and achieve the effect of simple processing, enriching machine tool processing technology, and dispelling concerns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further describe the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

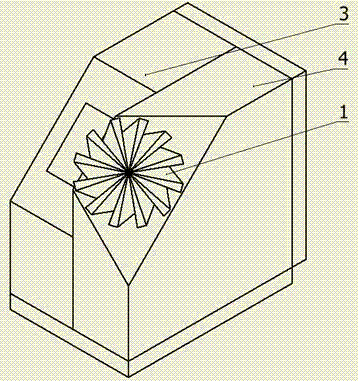

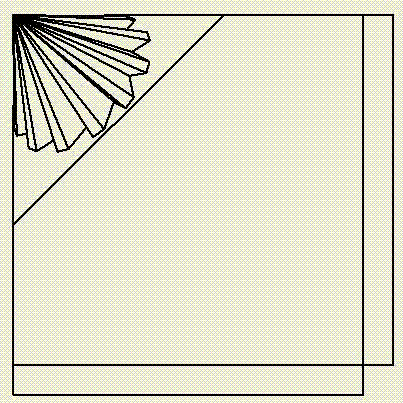

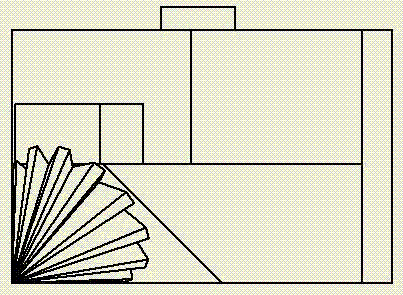

[0016] Such as Figure 1-Figure 5 As shown, a tool for processing right angles and obtuse edges in shallow blind holes includes a conical cutter head 1, a pair of helical gears 2, an upper cover 3 and a lower seat 4, and is characterized in that: the conical cutter head 1 It has a cone angle of 68°-72° and can be tangent to three mutually perpendicular planes at the same time. It can cut and process right-angled edges at the junction of the surfaces by rotation. When the angle between the two sides is greater than 90°, just let the tapered knife The obtuse edge can be processed by head 1 being tangent to the two surfaces twice; for example Figure 5 As shown, the pair of helical gears 2 have an included angle of 53 degrees to 57 degrees, so that the vertical rotation of the milling machine head become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com