Composite material of high-ductility die-reinforced fiber and aluminum alloy and preparation method thereof

A composite material and preparation technology, which is applied in the direction of metal layered products, synthetic resin layered products, lamination, etc., can solve the problems of high quality and poor corrosion resistance of aluminum alloy photovoltaic brackets, and achieve large market value and economy Prospect, good corrosion resistance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

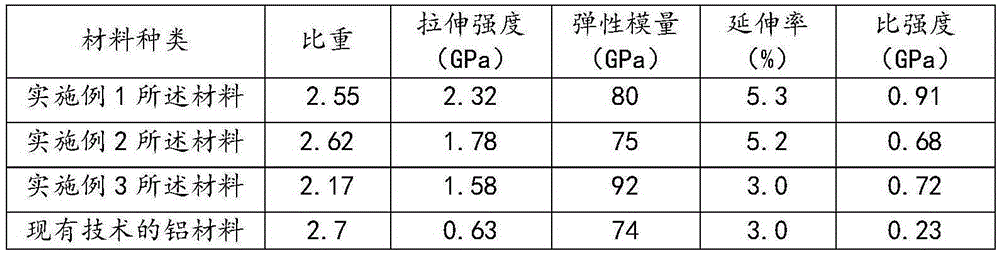

Embodiment 1

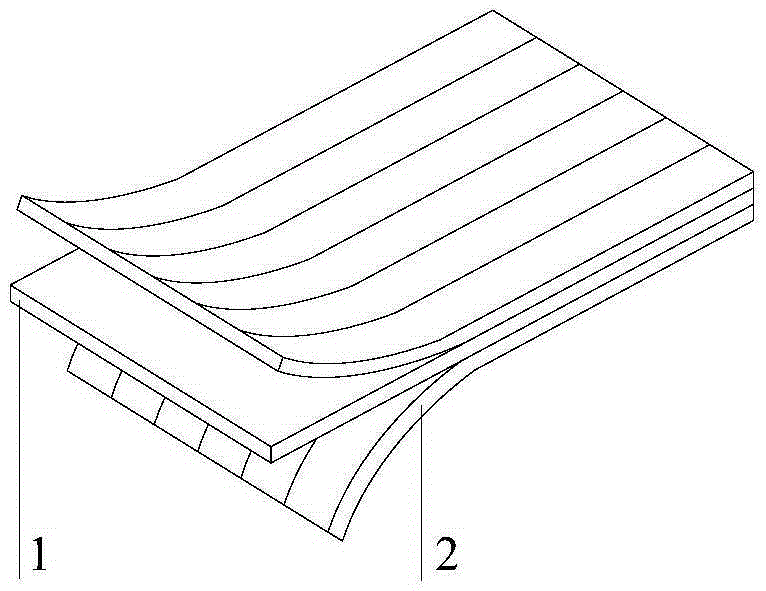

[0023] Example 1 This example discloses a high ductility mold reinforced fiber and aluminum alloy composite material, including:

[0024] A mandrel 1 and a high-ductility fiber-reinforced layer 2 wrapped on the outer surface of the mandrel; the mandrel 1 is aluminum alloy; the fiber-reinforced material of the high-ductility fiber-reinforced layer 2 is glass fiber or basalt fiber or aramid fiber.

[0025] The material of the glass fiber, basalt fiber or aramid fiber can be fiber cloth.

Embodiment 2

[0026] Example 2 This example discloses a high ductility mold reinforced fiber and aluminum alloy composite material, including:

[0027] The core mold 1 and the high ductility fiber reinforced layer 2 wrapped on the outer surface of the core mold; the core mold 1 is aluminum alloy; the fiber material of the high ductility fiber reinforced layer 2 is aramid fiber.

[0028] The material of the aramid fiber is fiber yarn.

Embodiment 3

[0029] Example 3 This example discloses a high ductility mold reinforced fiber and aluminum alloy composite material, including:

[0030] The core mold 1 and the high ductility fiber reinforced layer 2 wrapped on the outer surface of the core mold; the core mold 1 is aluminum alloy; the fiber material of the high ductility fiber reinforced layer 2 is basalt fiber.

[0031] The material of the basalt fiber is fiber mat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com