Production technology for non-woven-fabric dining table pad

A production process and non-woven technology, applied in the production process of non-woven table mats, can solve the problems of easy rolling, twisting, high cost, inconvenient use, etc., and achieve clear and clear patterns, increased toughness, and not easy to shift. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

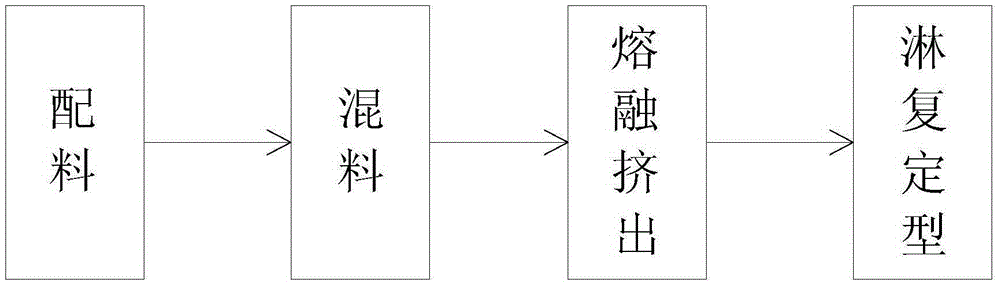

[0013] refer to figure 1 , the production process of a kind of non-woven table mat of the present invention, comprises the following steps: the first step, batching, the following raw material granules are made into mixture according to respective weight ratios: PE704240%, PPT30s10%, ground calcium carbonate 36 %, PE wax 9%, zinc stearate 3%, coupling agent 2%; the second step, mixing, the mixture obtained in the first step is run and stirred evenly in a high-speed mixer; the third step, melt extrusion , feeding the homogeneously mixed mixture in the second step into a melt extruder, and gradually controlling the temperature of the melt extruder to a temperature of 170-220 degrees Celsius, so that the mixture is melted and extruded and drawn into sheets; The fourth step, drenching and shaping, pass the pull piece obtained in the third step through the shaping cooling roller, and pad the front of the pulling piece with BOPP printing film, and the back pad with non-woven fabric,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com